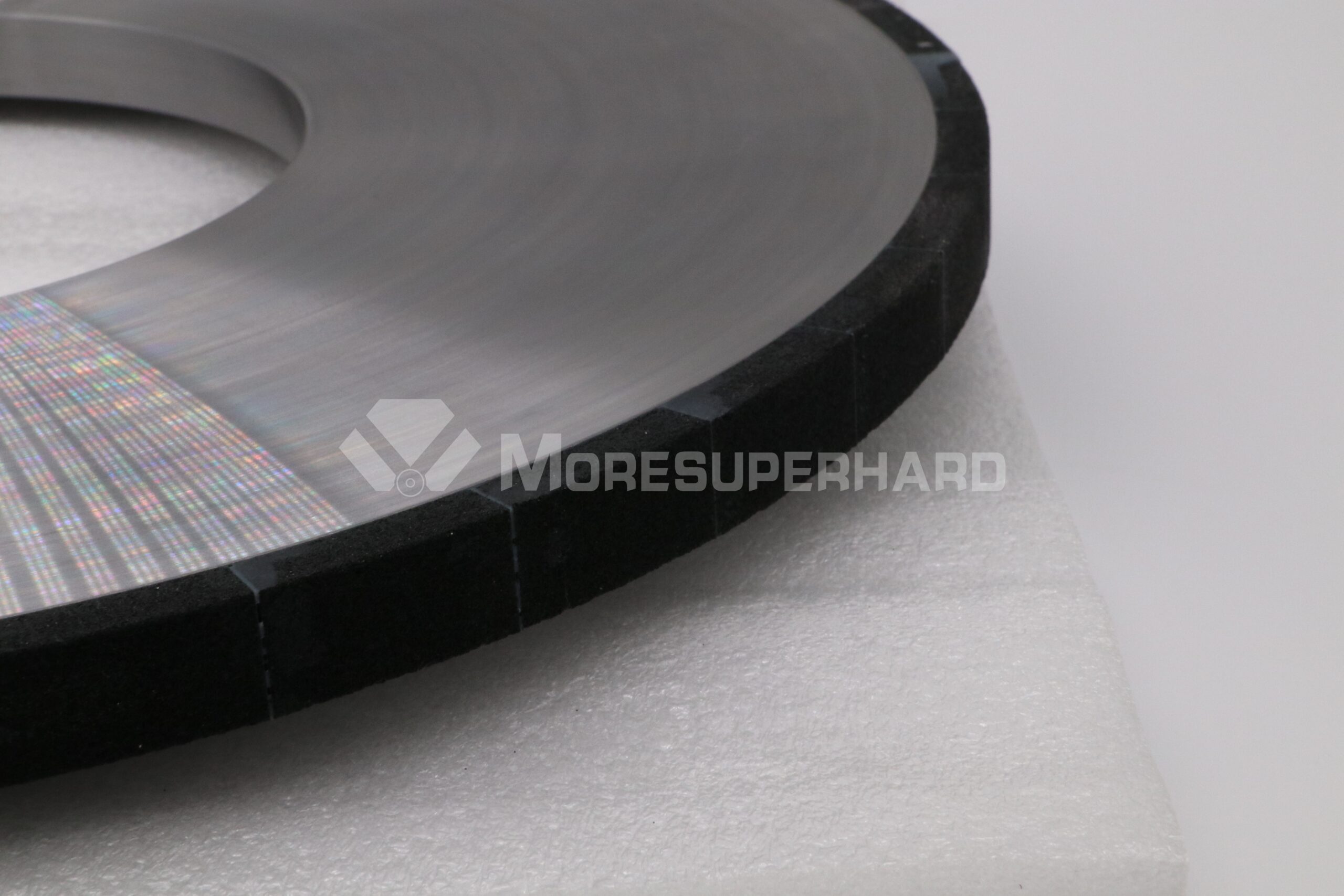

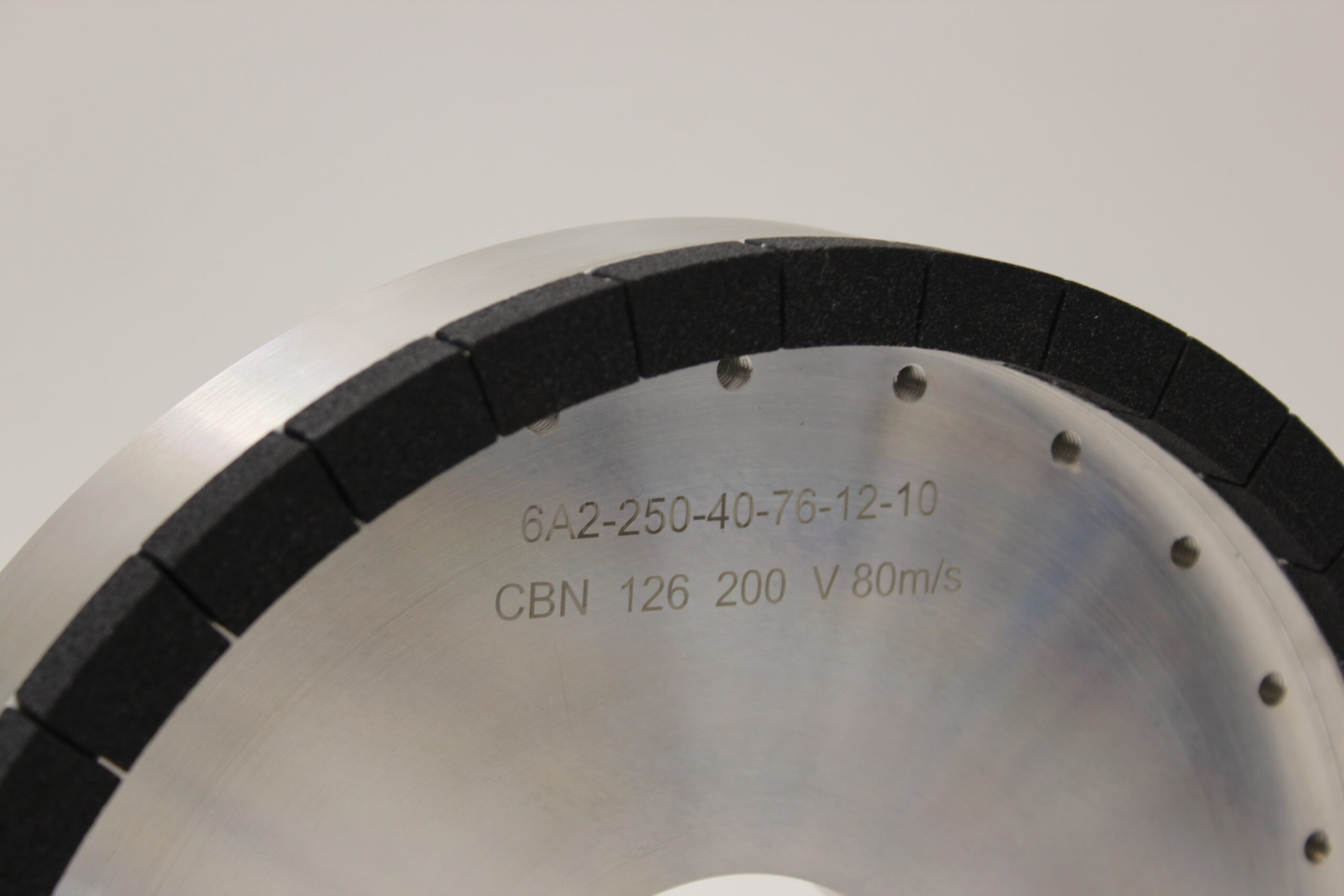

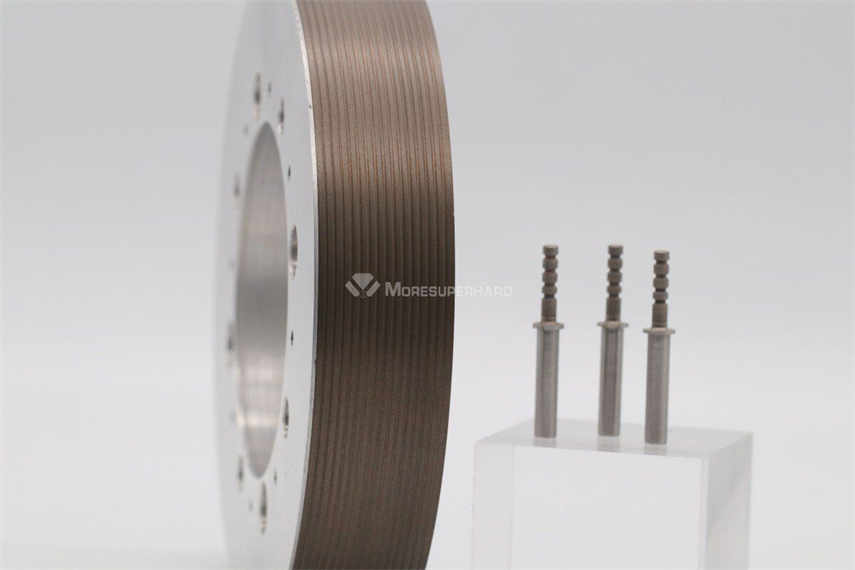

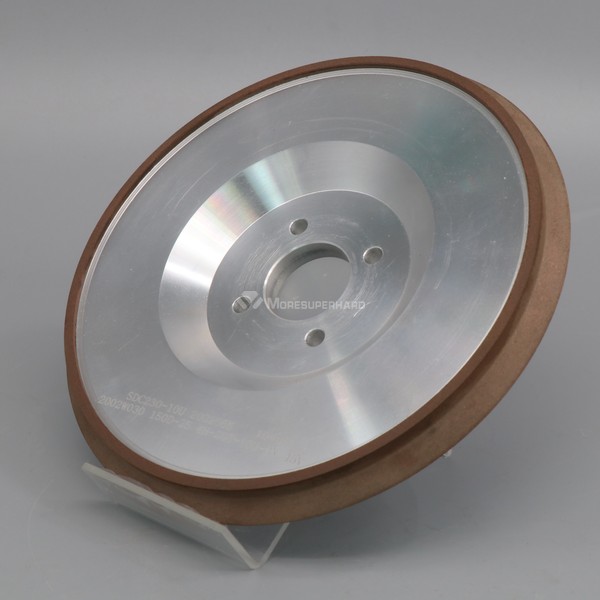

Vitrified Diamond Grinding Wheel for PCD Milling Cutter

Advantages of vitrified diamond wheels for PCD and PCBN tools :

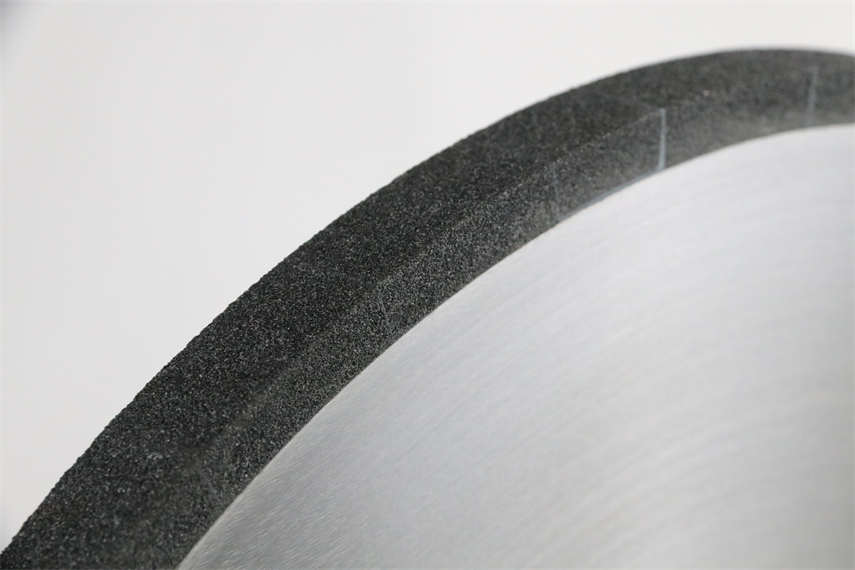

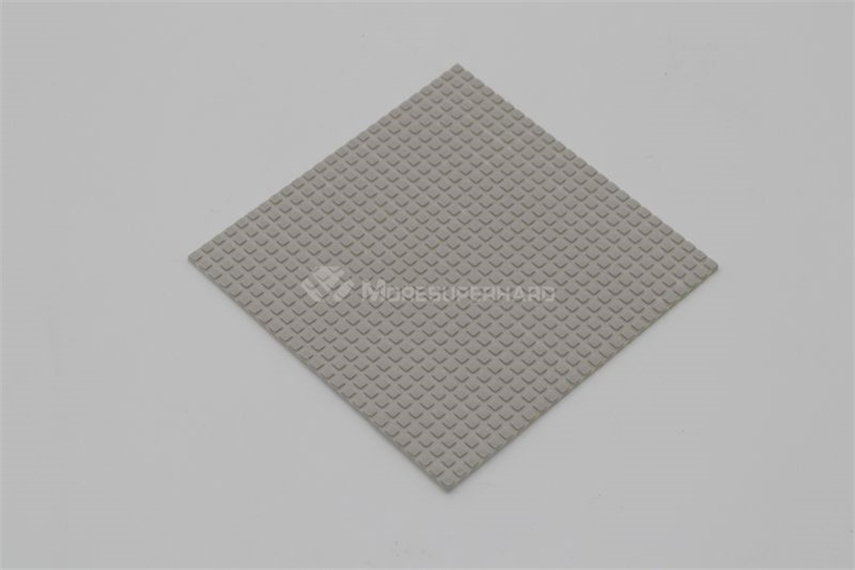

* The porous structure of the abrasive improved diamond exposure and Can Prevent Vertical Streaks On Workpiece And Improve Surface Quality

* Accurately control geometric tolerances to make a good abrasive layer

* Good Self-Sharpening, High Grinding Efficiency, High Wear Resistance And Less Abrasive Grain Consumption

* High Precision Workpiece. PCD Tools Can Reach High Efficiency, Good Surface Finish And Edge No Chipping

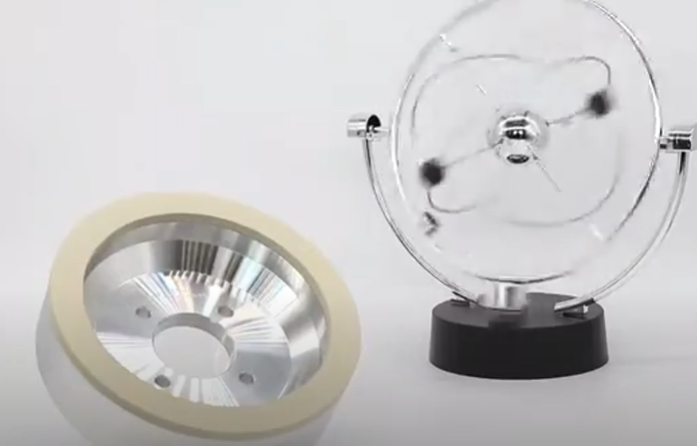

* Vitrified Bond Wheels Offer Tool Life Greater Than 150 Times That Of A Resin Bond Wheel And Can Be Easily Trued And Dressed On The Machine

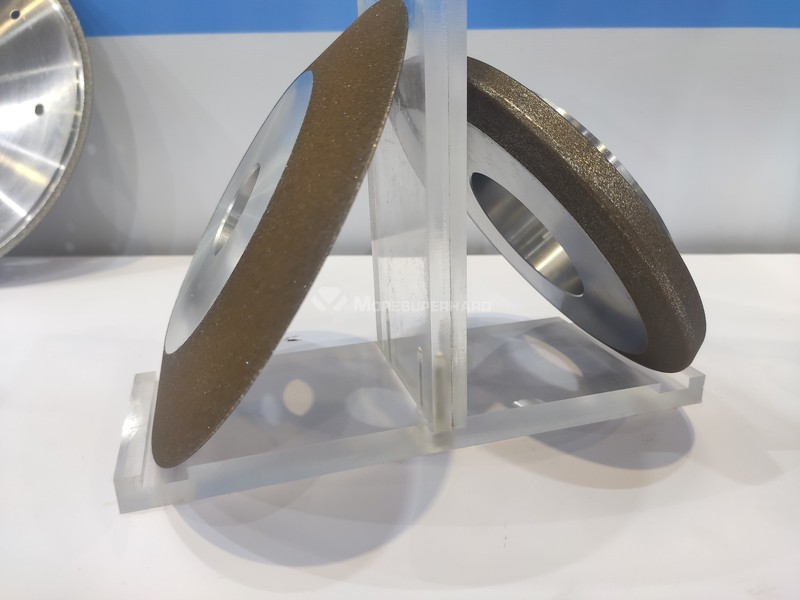

3A1 D 300 Vitrified Diamond Grinding Wheel for PCD Tools

Vitrified diamond grinding wheels possess pretty high abrasive resistance, especially in polishing hard and brittle workpieces. It has many advantages like small grinding force, low operating temperature, high grinding precision, excellent workpiece surface grinding, etc. Therefore, vitrified bond diamond grinding wheel will express better advantages in the future. It is recognized as a high-performance grinding wheel with a higher speed, higher efficiency, higher precision, lower abrading cost and lower pollution. Based on these superiorities, the vitrified bond diamond bruting wheel is widely used in wafers, PDC, PDC, diamond cutter, CBN, cemented carbide, new engineering structural ceramic, diamond, jewel, crystal, rare earth materials and other hard-brittle materials’ machining operation.

What are the applications of Moresuperhard’s vitrified diamond grinding wheels?

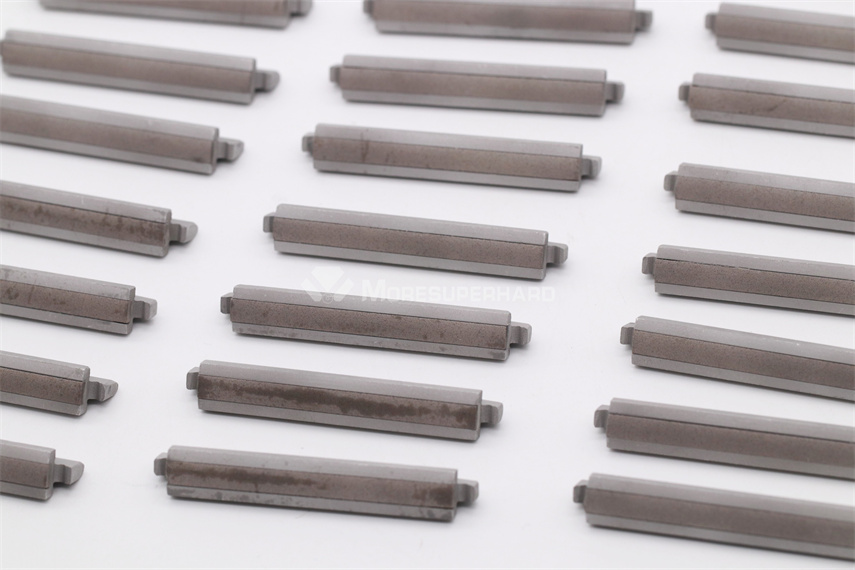

Mainly used for machining tungsten carbide, ceramic, cermets, optical glass, PCD, PCBN, CVD, natural diamond, stones and so on.

Features:

1. high speed,

2. high efficiency,

3. high precision.

4. long lifespan and easy to dress