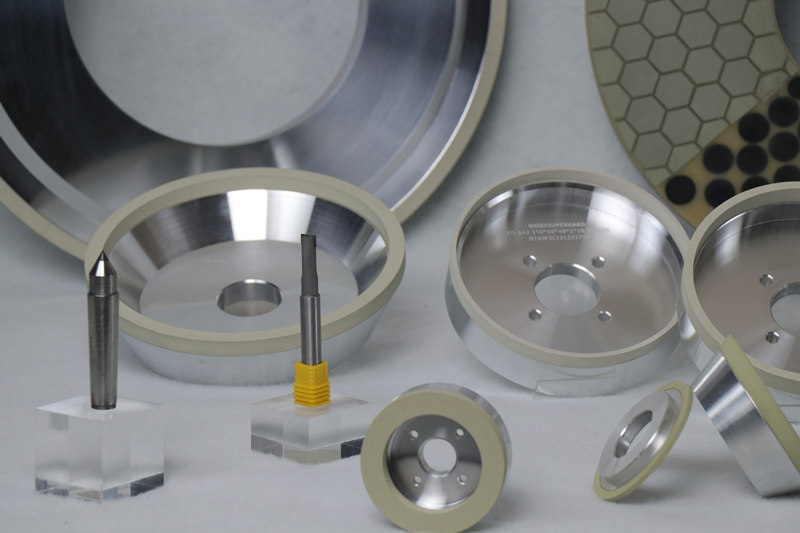

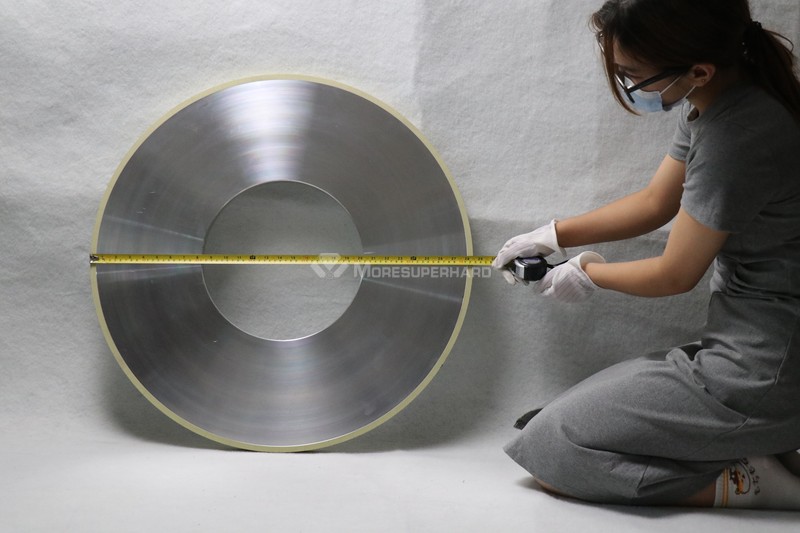

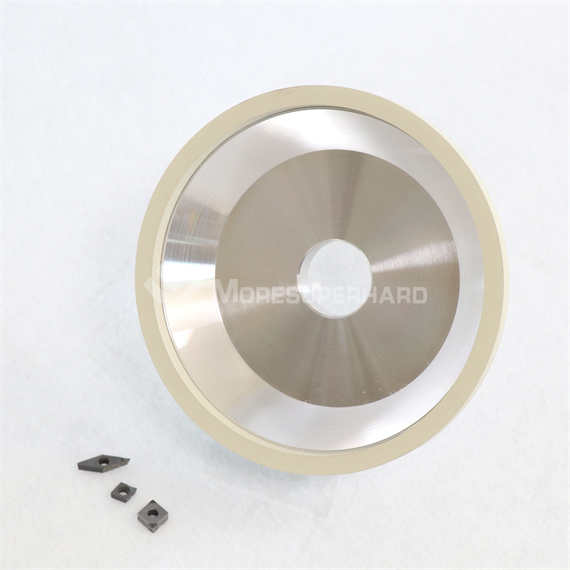

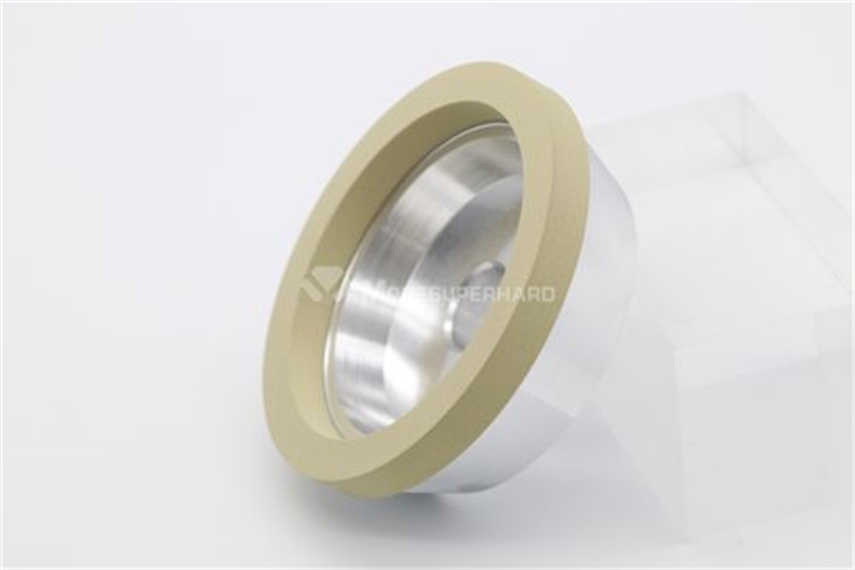

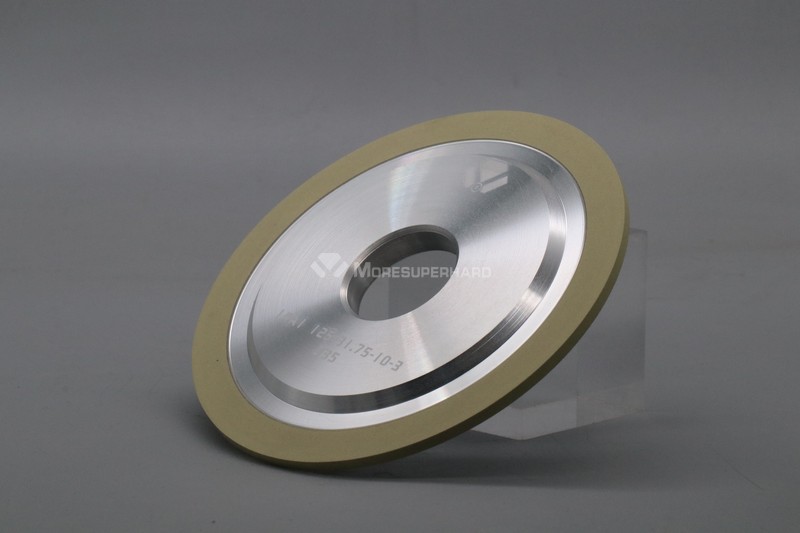

14A1 Vitrified diamond wheels manufacturer

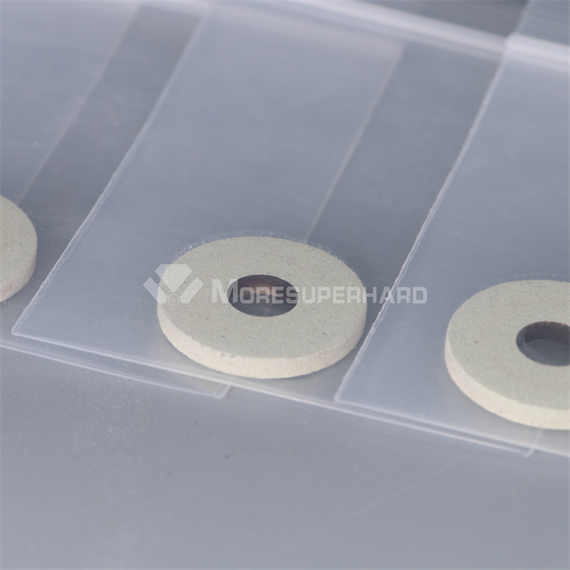

Vitrified diamond wheels widely used in wafers (semiconductor wafers and solar wafers), diamond composite wafers, diamond polycrystalline, diamond tools, cubic nitriding in developed countries in Europe and America. Boron, tungsten steel (hard alloy), new engineering structural ceramics, gemstones, crystals, rare earth materials (magnetic materials) and other high-hardness and brittle materials are machined, and good economic benefits have been achieved.

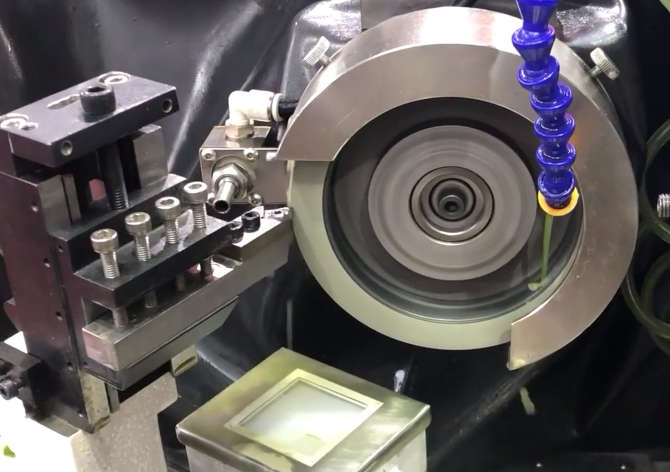

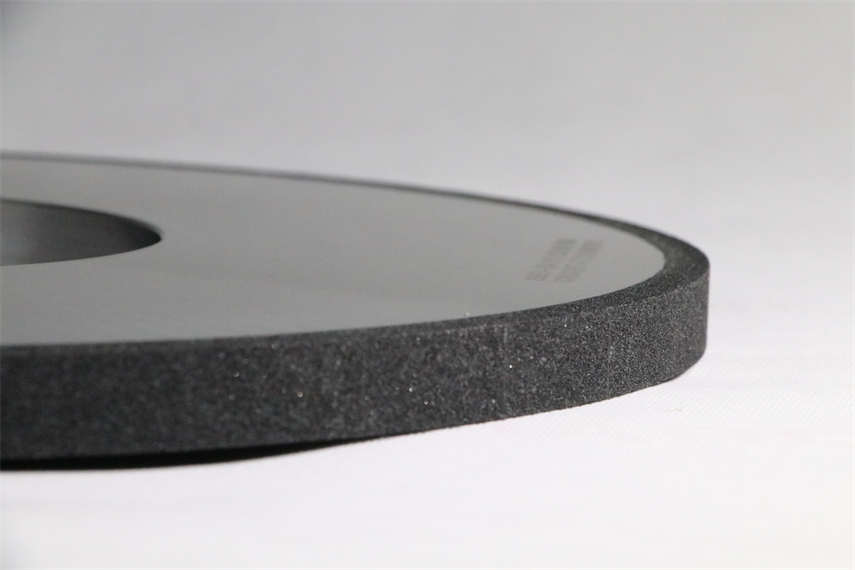

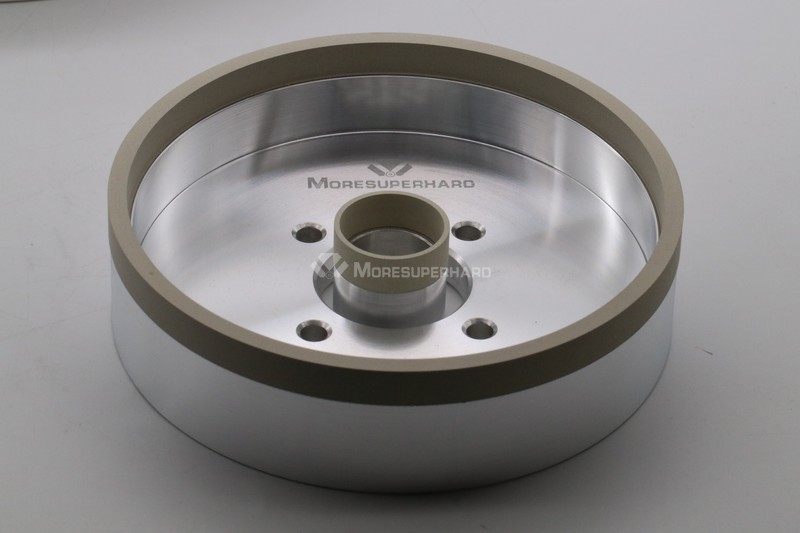

The vitrified bond diamond grinding wheel has high strength, good heat resistance, sharp cutting, high grinding efficiency, not easy to generate heat and blockage during the grinding process, and small thermal expansion to control the machining accuracy.

Compared with the resin bond grinding wheel, he solved the problem of the resin diamond grinding wheel’s low life, low grinding efficiency, and the variability of the grinding tool itself during the grinding process.

Based on the above-mentioned advantages of the vitrified grinding wheel bond diamond grinding wheel, its appearance was immediately widely used in

wafers (semiconductor wafers and solar wafers), diamond composite wafers, diamond polycrystalline, diamond tools, cubic nitriding in developed countries in Europe and America. Boron, tungsten steel (hard alloy), new engineering structural ceramics, gemstones, crystals, rare earth materials (magnetic materials) and other high-hardness and brittle materials are machined, and good economic benefits have been achieved.