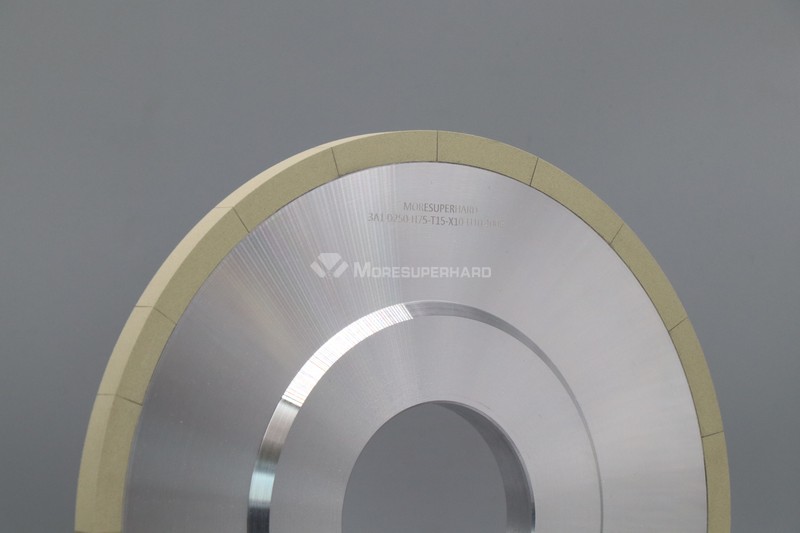

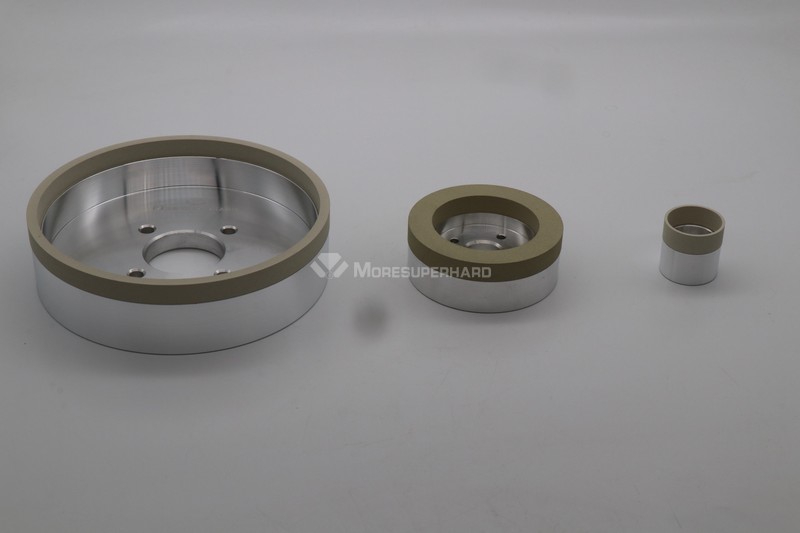

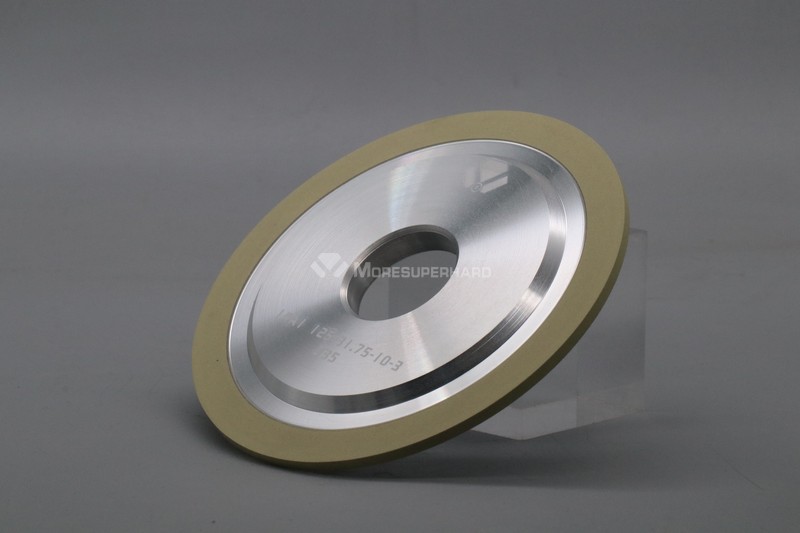

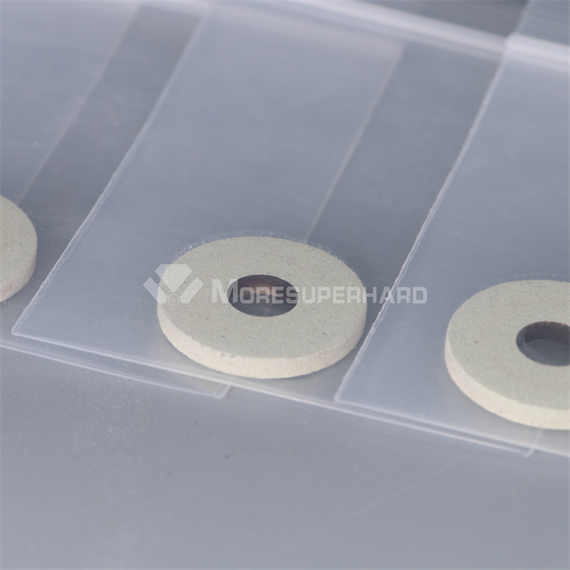

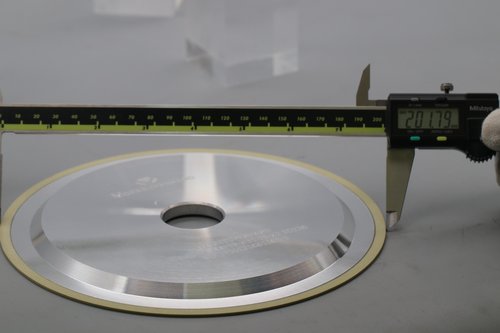

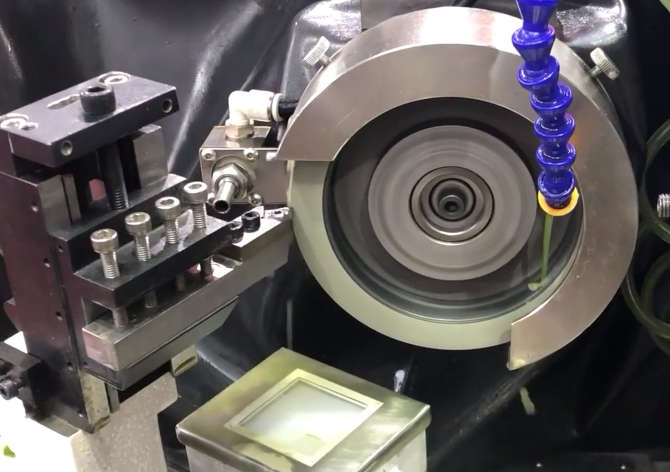

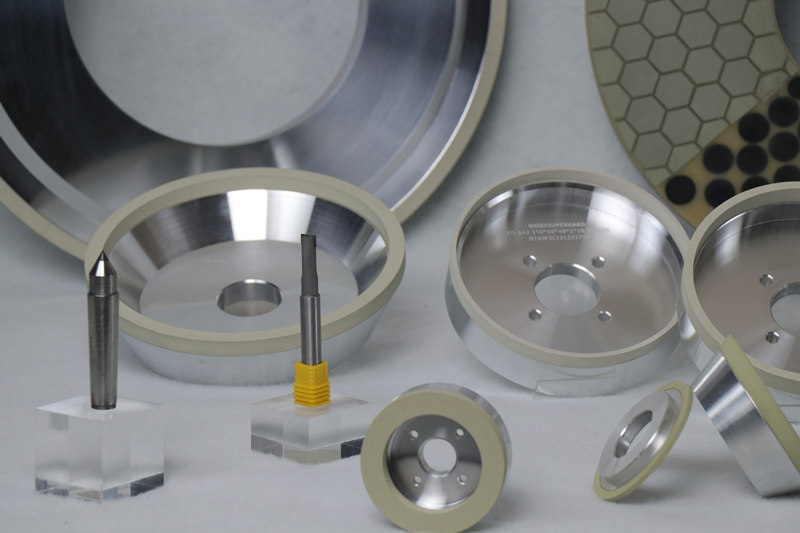

Ceramic diamond wheels, cylindrical grinding PCD bearing

Ceramic bond diamond grinding wheel has the characteristics of high temperature resistance, high efficiency, good rigidity, and good shape retention.

Used for processing PCD bearing, it can sharpen the surface quality to the maximum. Its grinding efficiency is twice that of resin bond, and its wear resistance is high, the grinding ratio is small, and the service life of the grinding wheel is as long as 4 times.

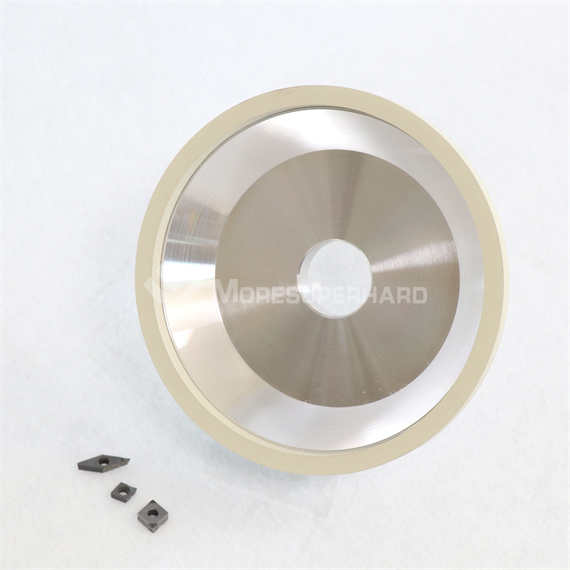

More Superhard company specializes in the production of PCD tool special ceramic bond diamond grinding wheels, which are mainly used for the sharpening of the front angle, back angle and side of the circular saw blade of cemented carbide, high-speed steel, cermet, PCD and other materials, and the band saw. The product has excellent performance and low price, welcome friends in the industry to buy.

The advantages of ceramic bond diamond wheels (compared with resin diamond grinding wheel)

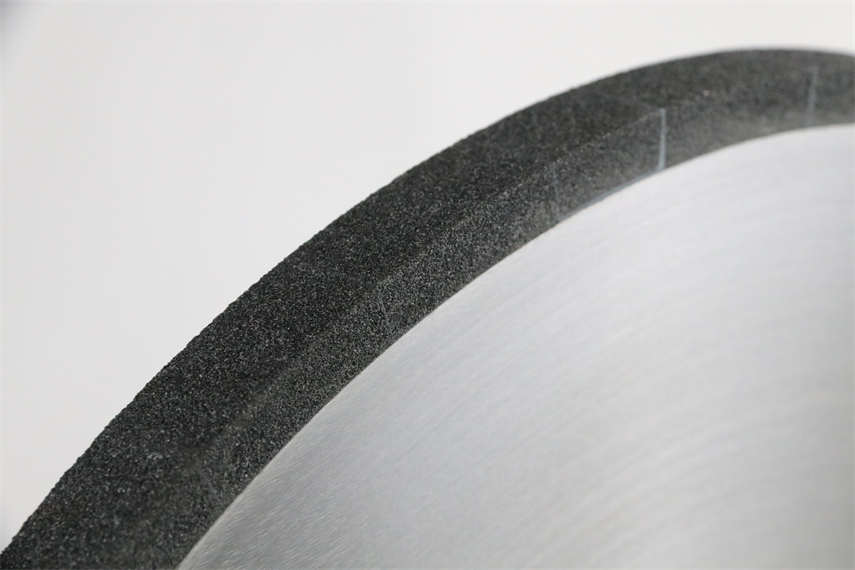

1. High durability and good shape retention: its durability is 2-3 times that of resin grinding wheels under the same grinding conditions. The grinding wheel has strong abrasive grain binding force, uniform and stable wear, and the shape of the grinding wheel is not easy to change;

2. Good sharpness: its grinding efficiency is about twice that of resin grinding wheels;

3. Good repairability: it has the same repairability as ordinary ceramic corundum and silicon carbide grinding wheels;

4. It is superior in the production of grinding wheels with a particle size of 0-5μm for superfinishing, which is the bottleneck of resin grinding wheels;