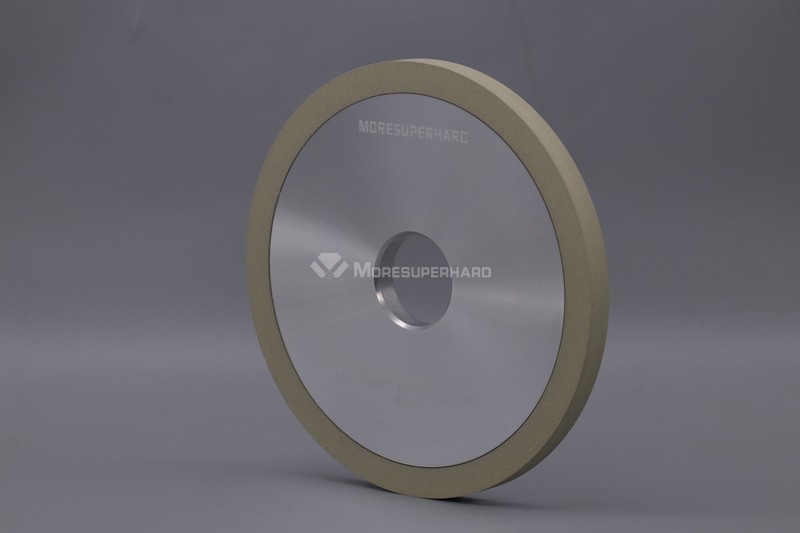

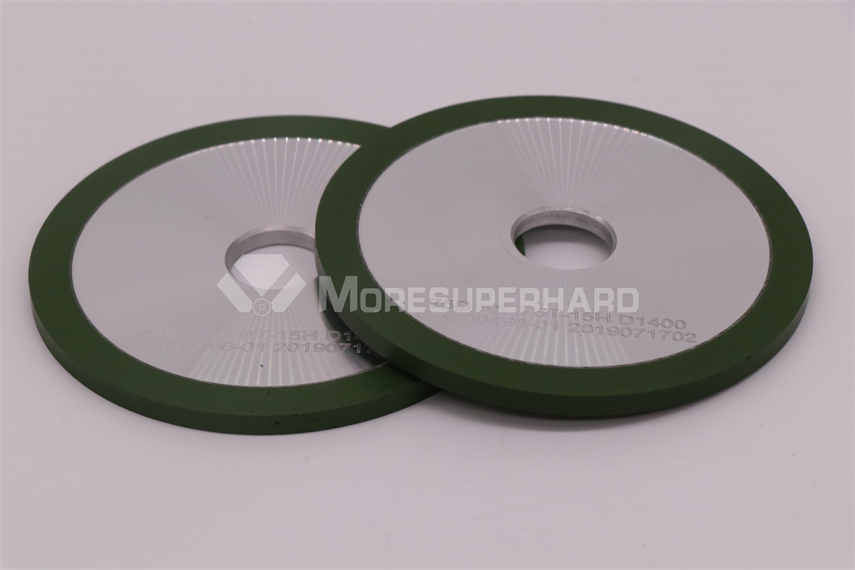

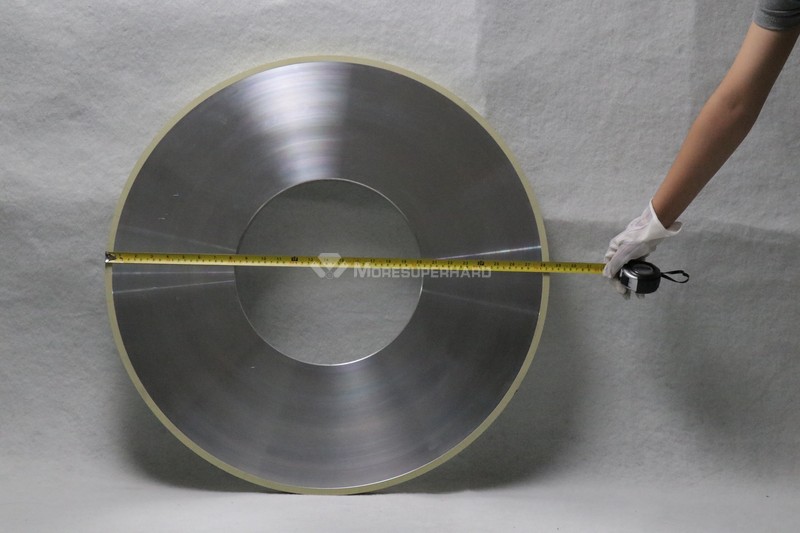

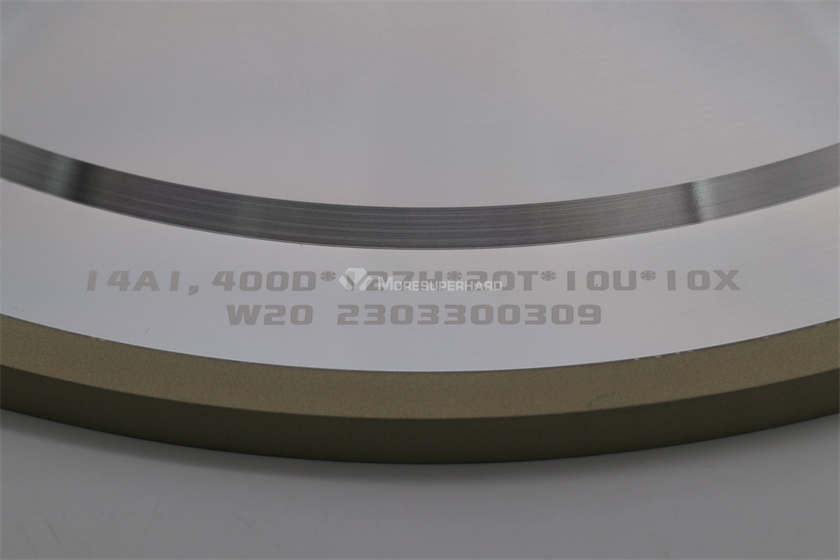

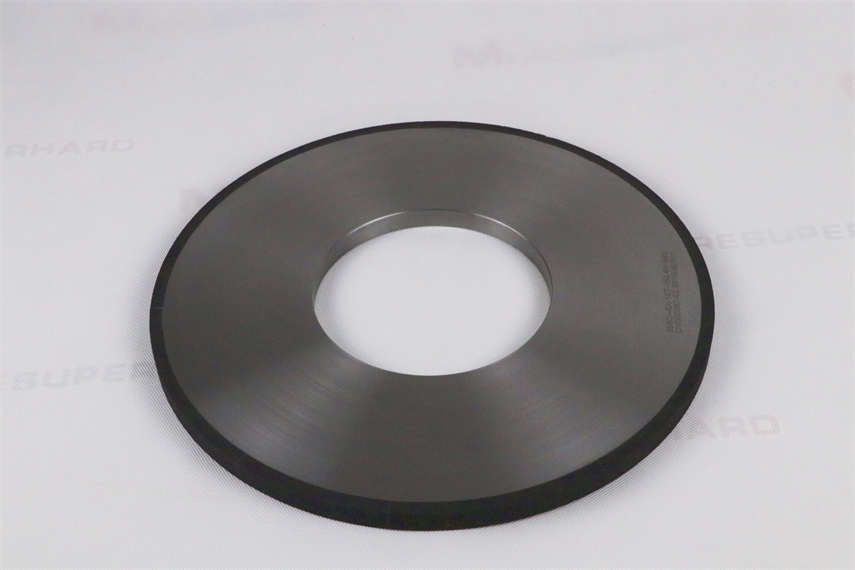

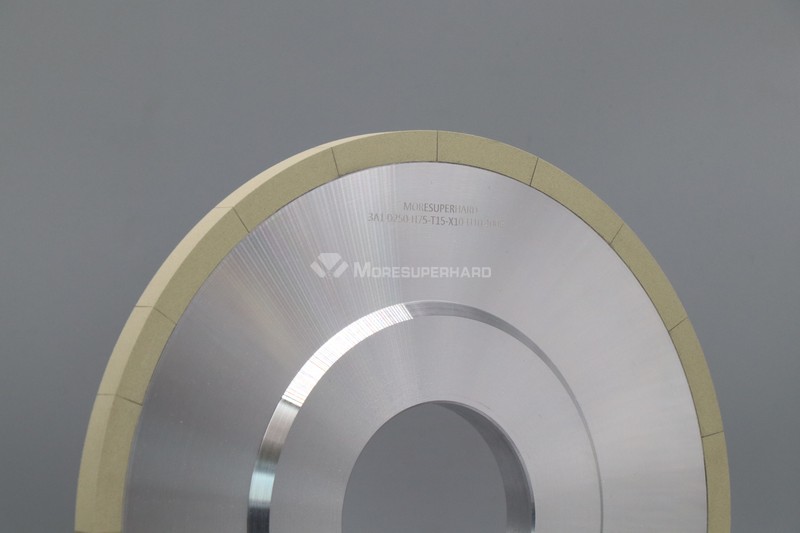

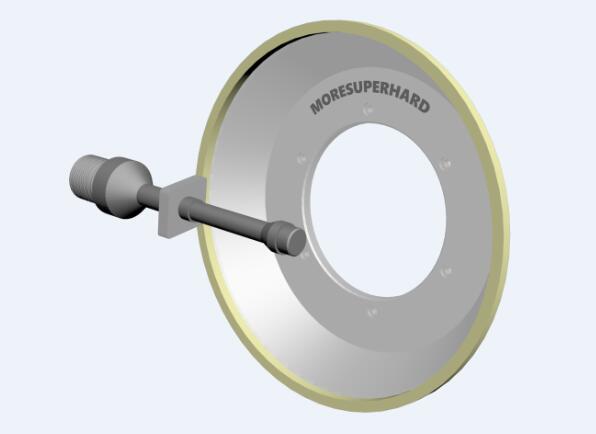

Vitrified grinding wheel abrasive diamond manufacturer

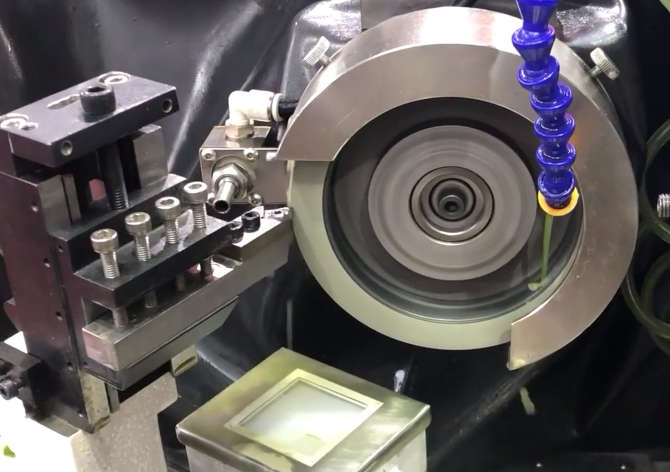

Vitrified grinding wheel abrasive diamond can be utilized in numerous grinding applications. These include but are not limited to:

Medical Device and Instrument Manufacturing

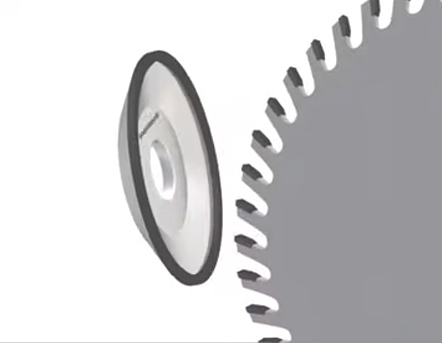

PCD & PCBN Tool Grinding

Ball Screw Grinding

Automotive Manufacturing

Aerospace Parts

Wind Turbine Manufacturing

Cutting tools manufacturing

Advanced Moresuperhard vitrified grinding wheels abrasive diamond are manufactured to create higher levels of porosity.

The vitrified grinding wheel abrasive diamond has high strength, good heat resistance, sharp cutting, high grinding efficiency, not easy to generate heat and blockage during the grinding process, small thermal expansion, and easy to control the machining accuracy. Compared with the resin bond diamond grinding wheel, it solves the low life of the resin diamond grinding wheel, the grinding efficiency is low, and the grinding tool itself is in the grinding process.

Applications of Vitrified grinding wheel abrasive diamond

Mainly used in silicon wafer, Led wafer, polycrystalline diamond compact PDC, diamond polycrystalline (PCD), diamond cutting tools, cubic boron nitride (CBN), tungsten carbide, cemented carbide, new engineering structural ceramics, crystals, magnetic materials, optical glass and other high hard brittle materials machining.