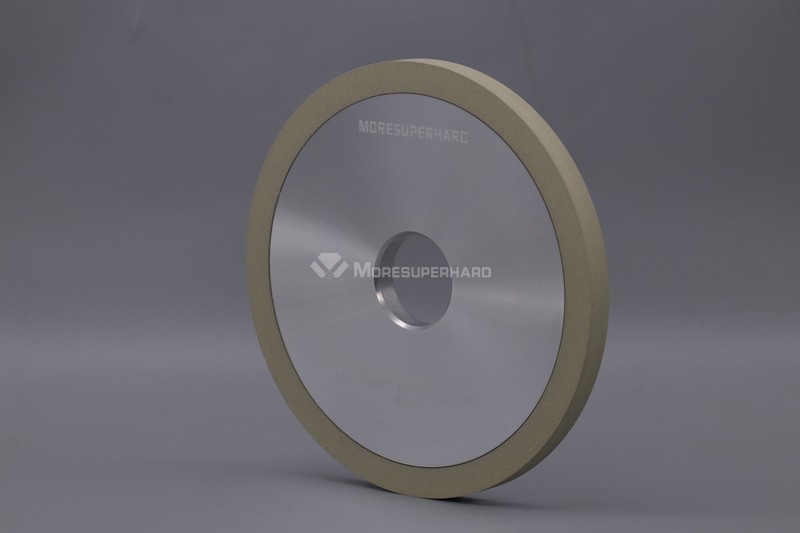

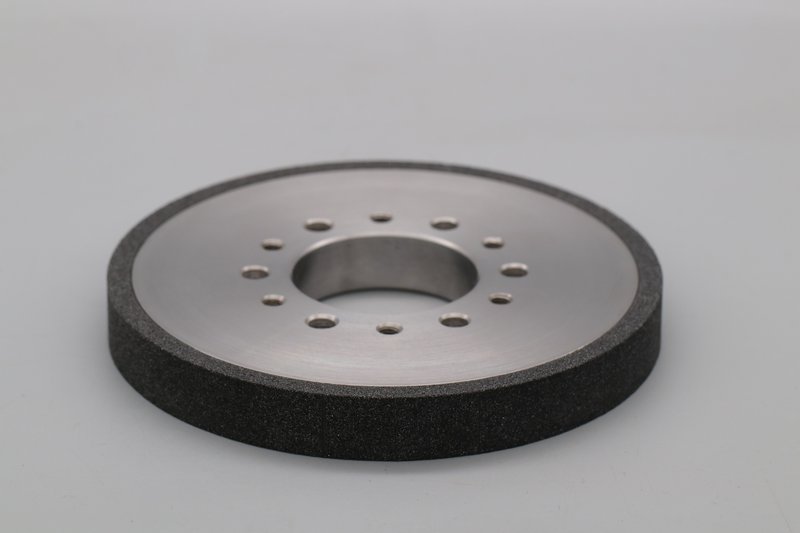

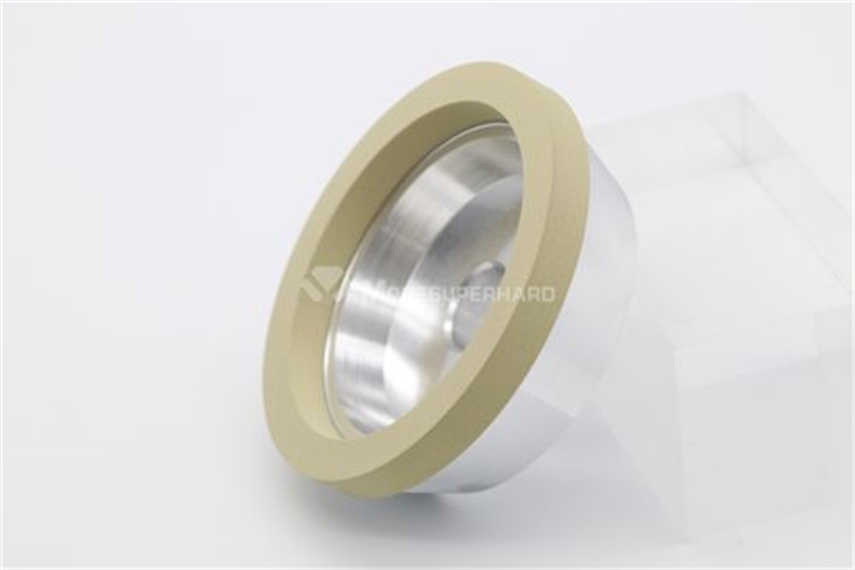

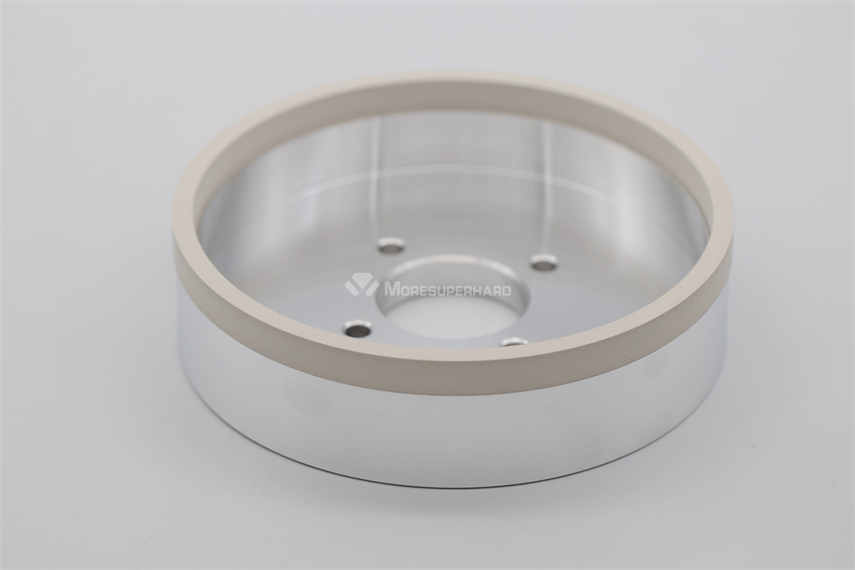

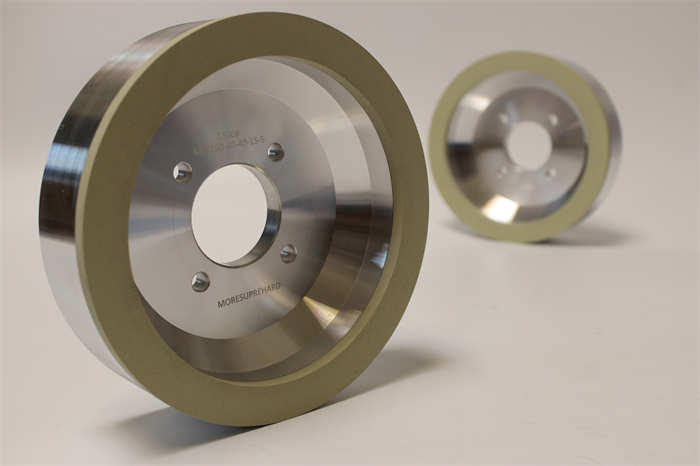

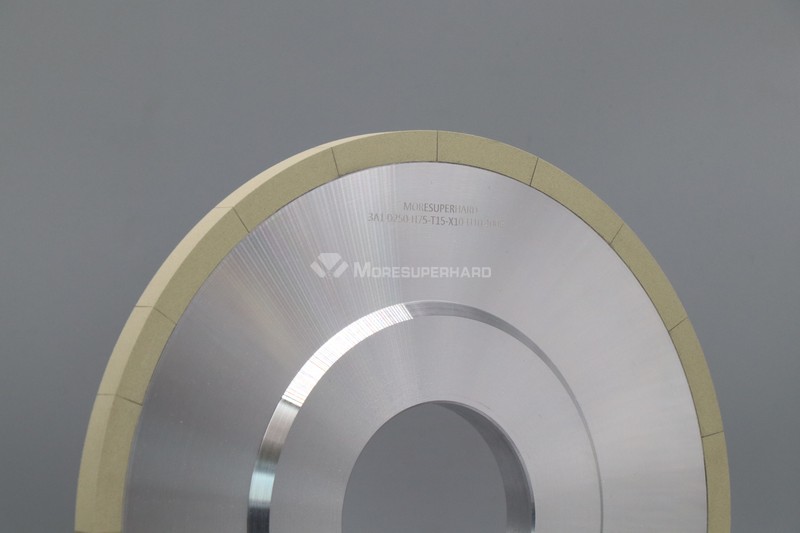

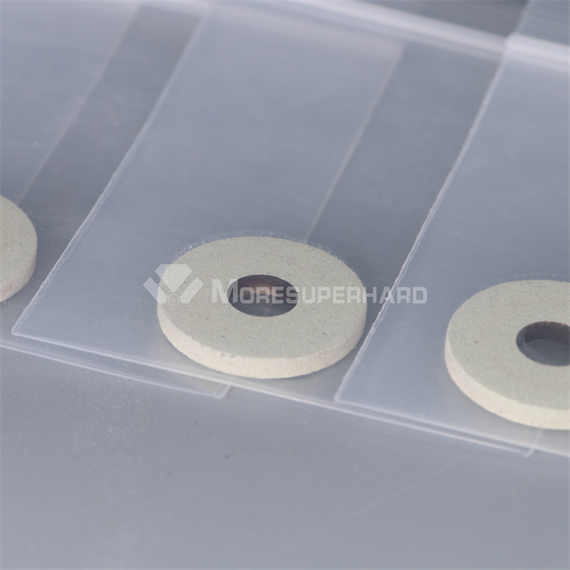

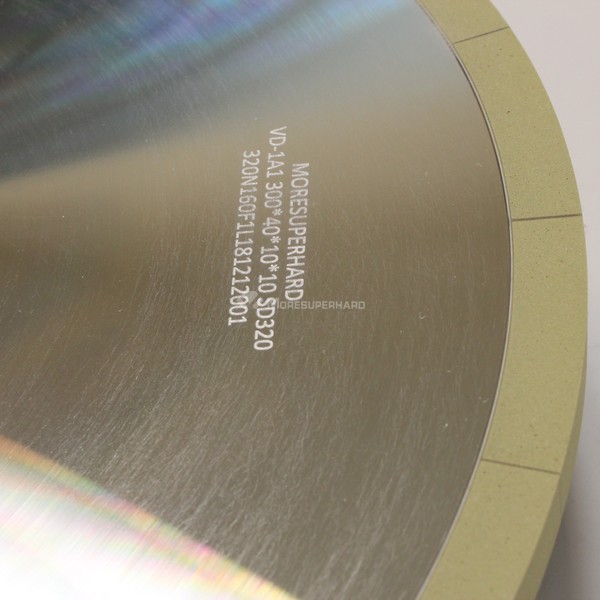

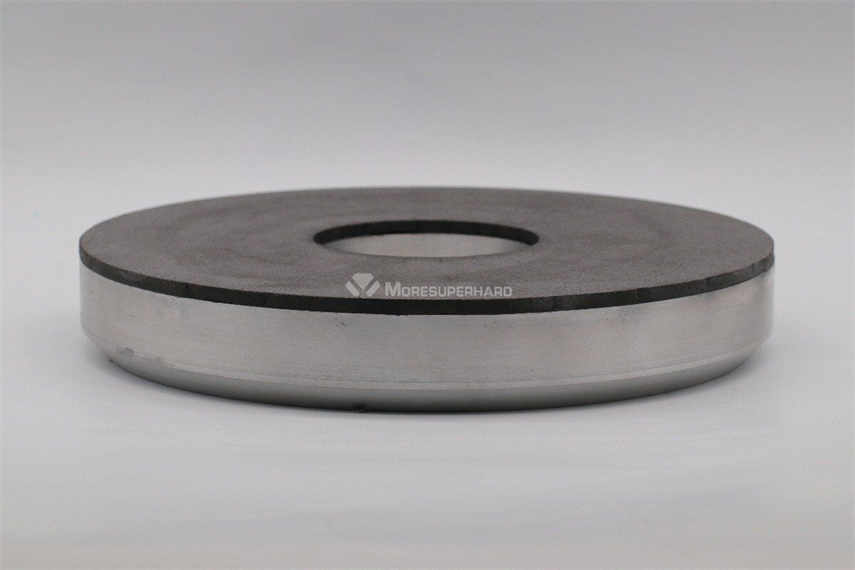

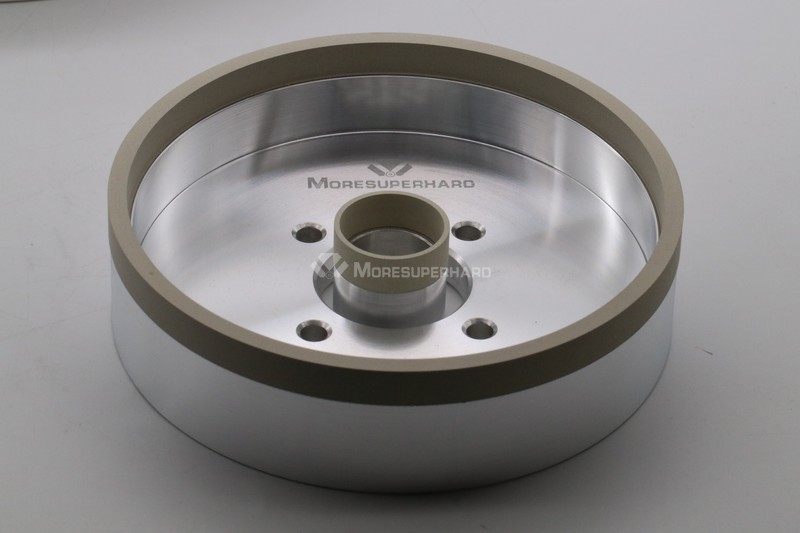

Vitrified diamond wheel for hvof carbide coated

Vitrified diamond wheels for Roll grinding and grinding of thermal spray coatings ( including tungsten carbide , chrome carbide and chrome oxide ), ceramics, carbides, chilled iron composites and other hard-to-grind materials.

Diamond grinding wheel for thermal spraying coating industry. Thermal spraying technology is used for producing coatings components or to reconditioning damaged parts.

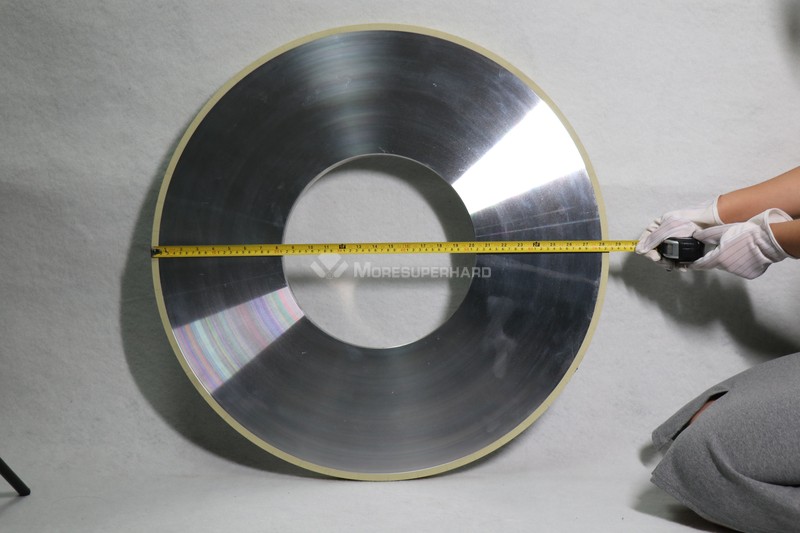

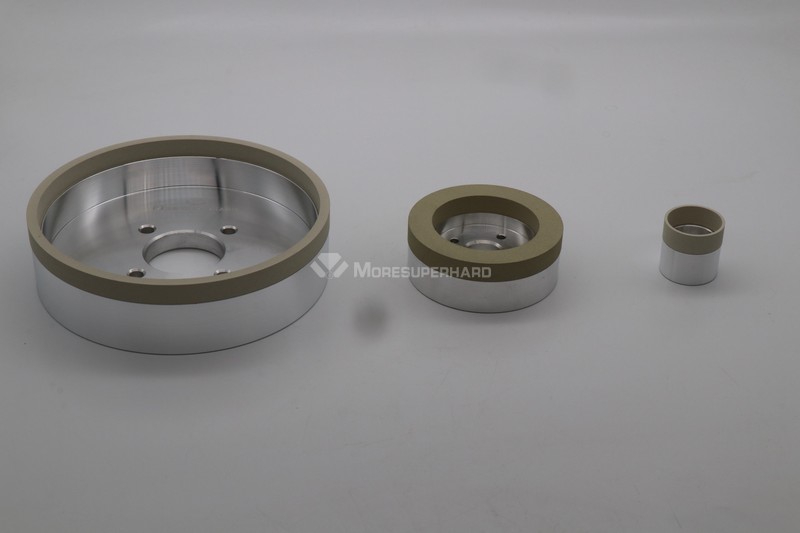

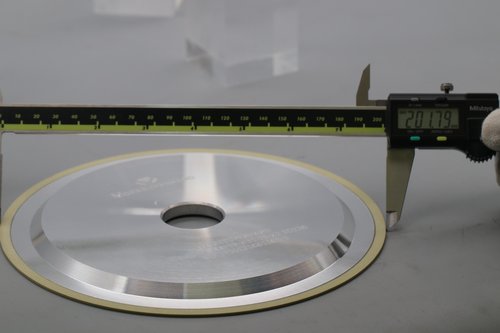

Diameter: 43″ (1100mm) – 1″ (25mm)

Thermal Spray Coating Process

Thermal Spray technologies includ Flame wire spray, Arc spray, Plasma spray, HVOF or HVAF , Detonation Spray, Cold spray .Thermal spraying technology is widely used in aerospace, aviation, machinery, metallurgy, chemical, petroleum, coal, railway, textile and many other departments .

Application fields of HVOF carbide coatings

* Engineering machinery wearing parts

*Wire and cable industry wearing parts

*Metal products industry wearing parts

*Power plant equipment wearing parts

*Petrochemical equipment Customization and repair of wearing parts

Specification for Vitrified diamond wheel for hvof carbide coated

| Type | D | X | U |

| 1A1 | 100 | 5,10,15,20 | 3-12 |

| 1A1 | 125 | 5,10,15,20 | 3-12 |

| 1A1 | 150 | 2,3,4,5,8,10,15,20 | 3-12 |

| 1A1 | 170 | 14 | 3-12 |

| 1A1 | 175 | 10,20 | 3-12 |

| 1A1 | 200 | 5,10 | 3-12 |

| 1A1 | 250 | 5,10 | 3-12 |

| 1A1 | 300 | 10 | 5-10 |

| 1A1 | 350 | 10 | 5,10,30,40,50 |

| 1A1 | 400 | 10,25 | 5,10 |

| 1A1 | 500 | 10 | 5,10 |

| 1A1 | 620 | 10 | 25 |

| 1A1 | 720 | 10 | 25 |