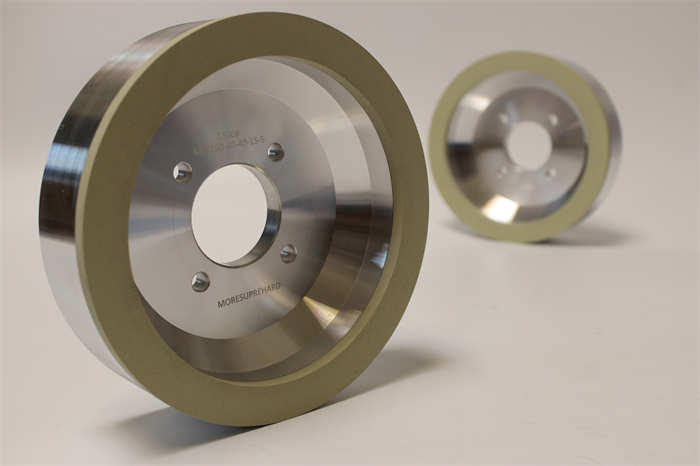

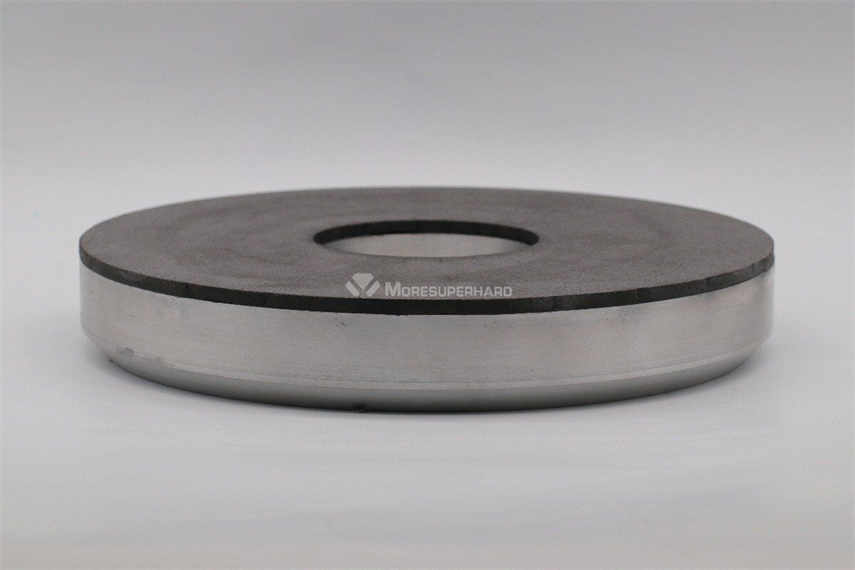

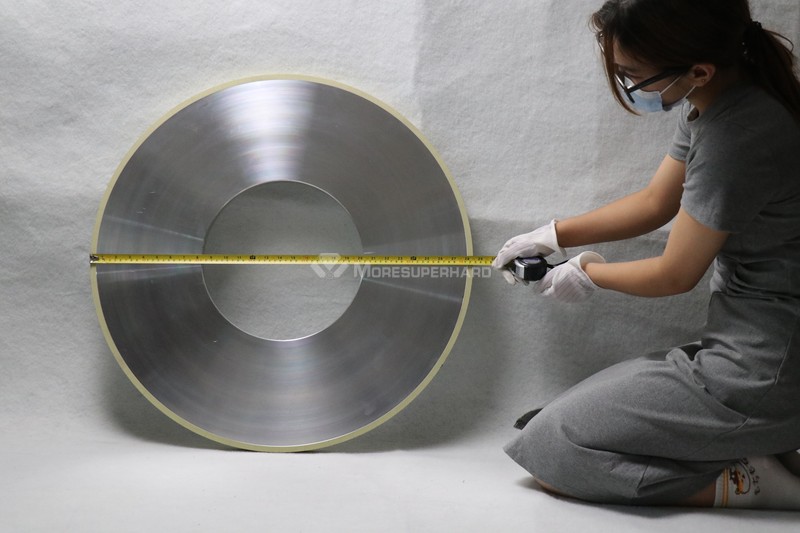

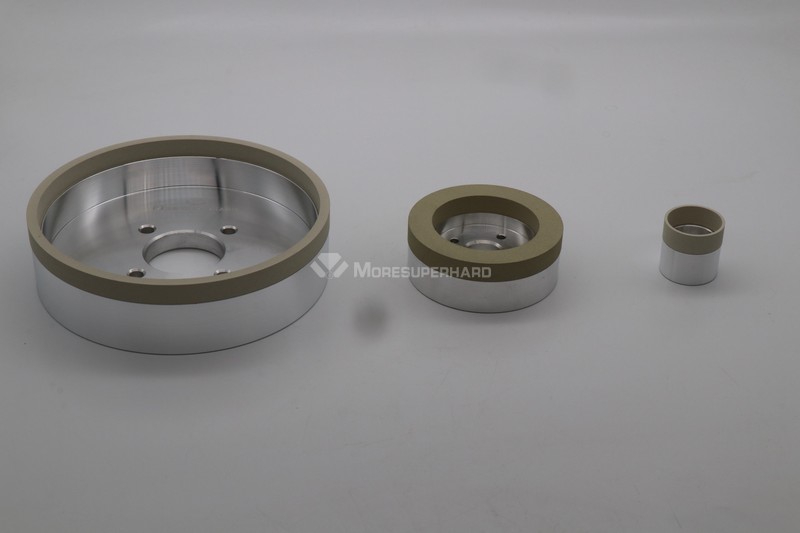

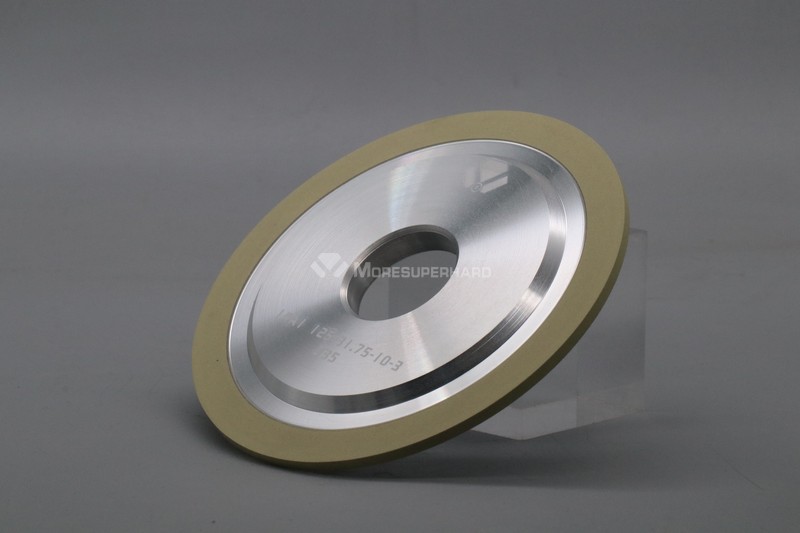

D125mm Vitrified diamond wheels for sale

Vitrified diamond wheels for sharpening circular saw blade of cemented carbide, high-speed steel, cermet, PCD, CBN, cvd, mcd, and band saw

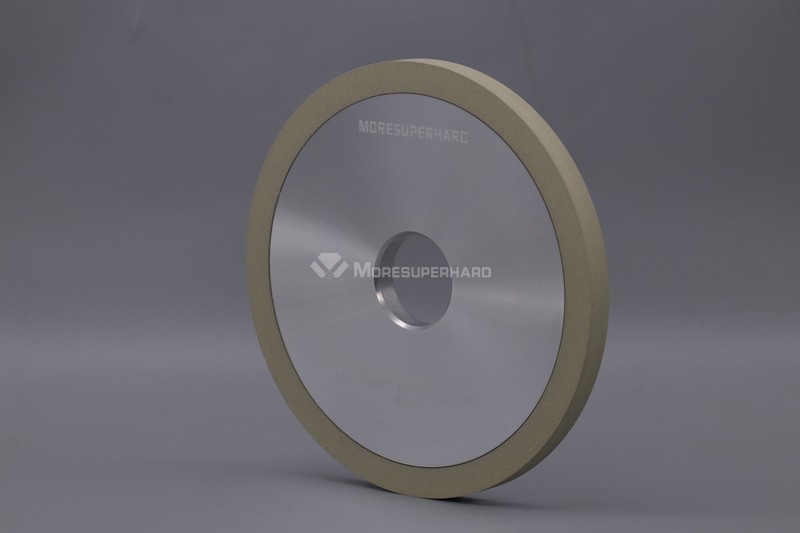

Size of vitrified diamond wheel: D125x T5x H20x W5

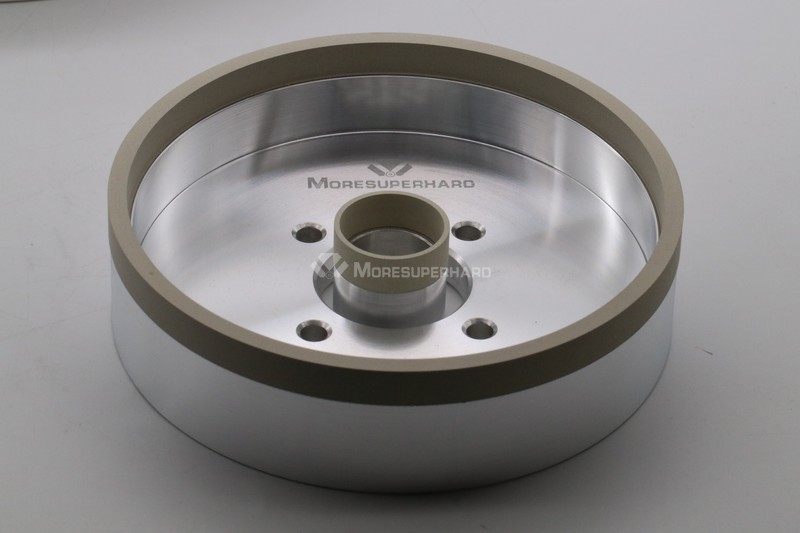

Type of vitrified diamond wheel: 14a1 diamond wheel

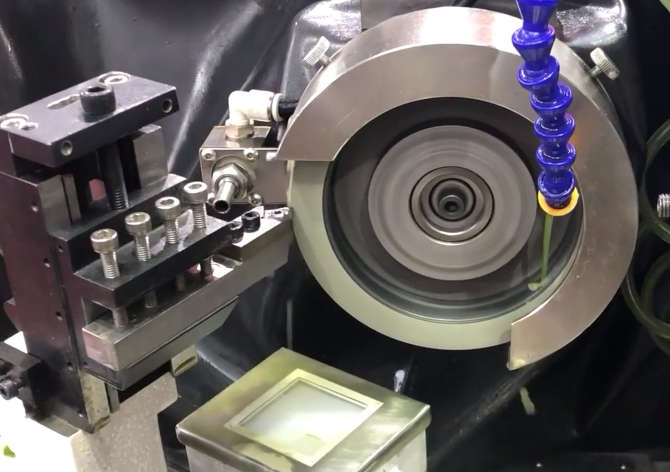

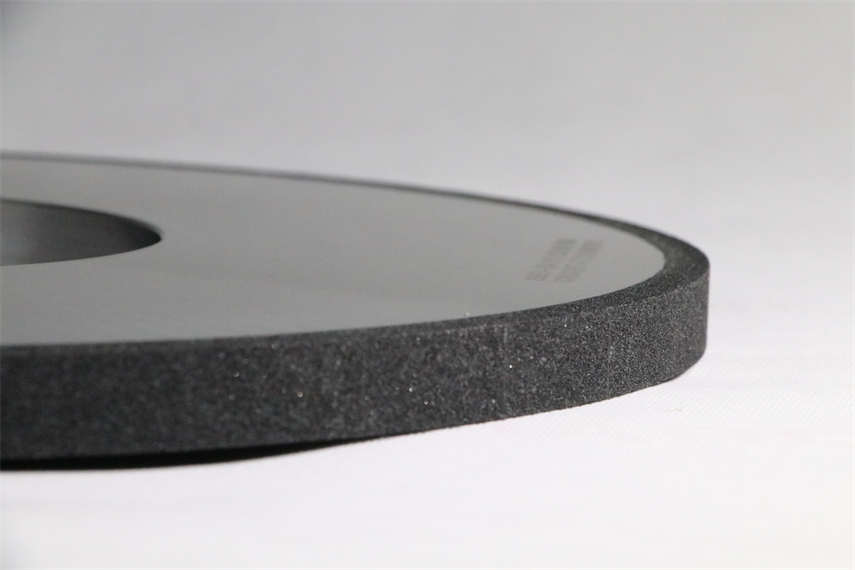

The vitrified bond diamond grinding wheel has high strength, good heat resistance, sharp cutting, high grinding efficiency, not easy to generate heat and blockage during the grinding process, and small thermal expansion to control the machining accuracy. Compared with the resin bond grinding wheel, he solved the problem of the resin diamond grinding wheel’s low life, low grinding efficiency, and the variability of the grinding tool itself during the grinding process. Based on the above-mentioned advantages of the ceramic grinding wheel bond diamond grinding wheel, its appearance was immediately widely used in wafers (semiconductor wafers and solar wafers), diamond composite wafers, diamond polycrystalline, diamond tools, cubic nitriding in developed countries in Europe and America. In the machining of high hard and brittle materials such as boron, tungsten steel (hard alloy), new engineering structural ceramics, gemstones, crystals, rare earth materials (magnetic materials)

Features of vitrified diamond wheels (compared with resin diamond grinding wheel)

1. High durability and good shape retention: its durability is 2-3 times that of resin grinding wheels under the same grinding conditions. The grinding wheel has strong abrasive grain binding force, uniform and stable wear, and the shape of the grinding wheel is not easy to change;

2. Good sharpness: its grinding efficiency is about twice that of resin grinding wheels;

3. Good repairability: it has the same repairability as ordinary ceramic corundum and silicon carbide grinding wheels;

4. It is superior in the production of grinding wheels with a particle size of 0-5μm for superfinishing, which is the bottleneck of resin grinding wheels;

5. Compared with resin grinding wheel, the comprehensive cost of grinding process can be reduced by 20%-30%.