Home » Grinding Wheels » Vitrified bond Diamond CBN Wheels » High Cermet grinding, vitrified diamond grinding wheels

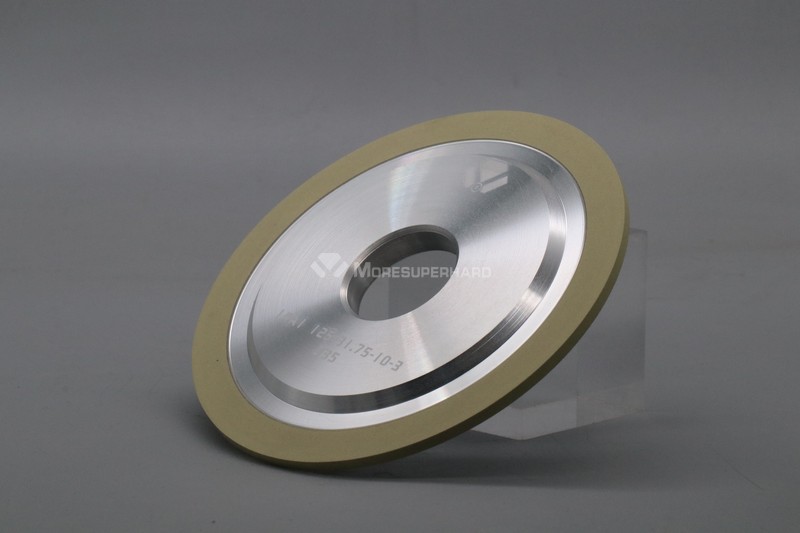

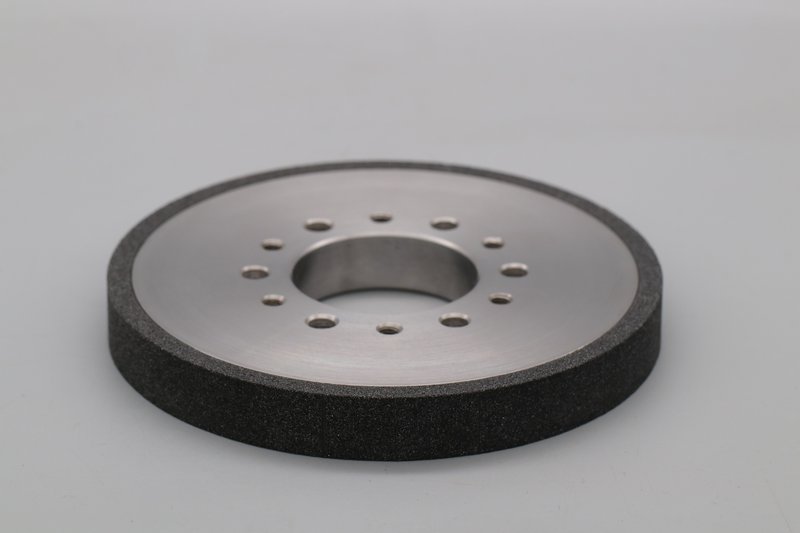

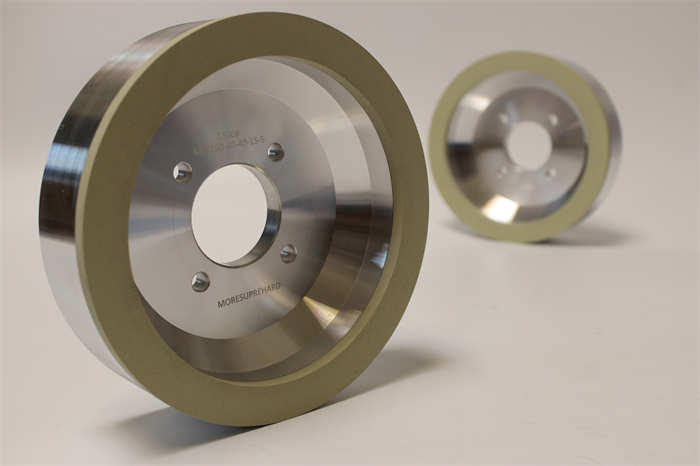

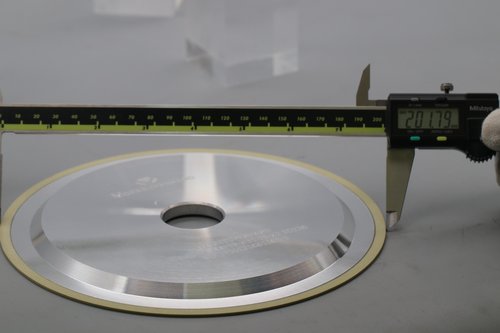

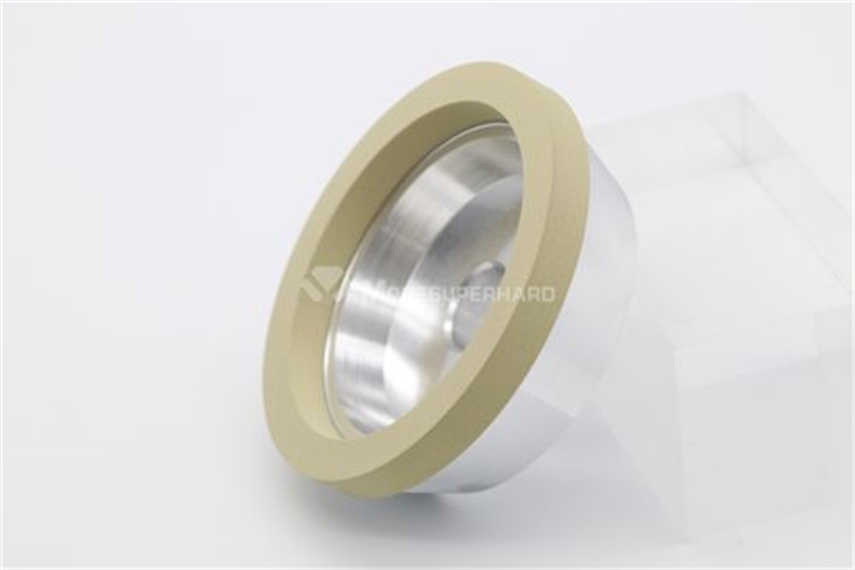

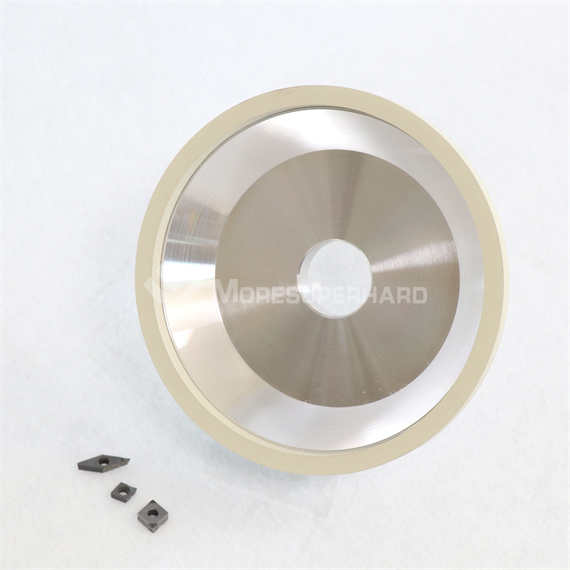

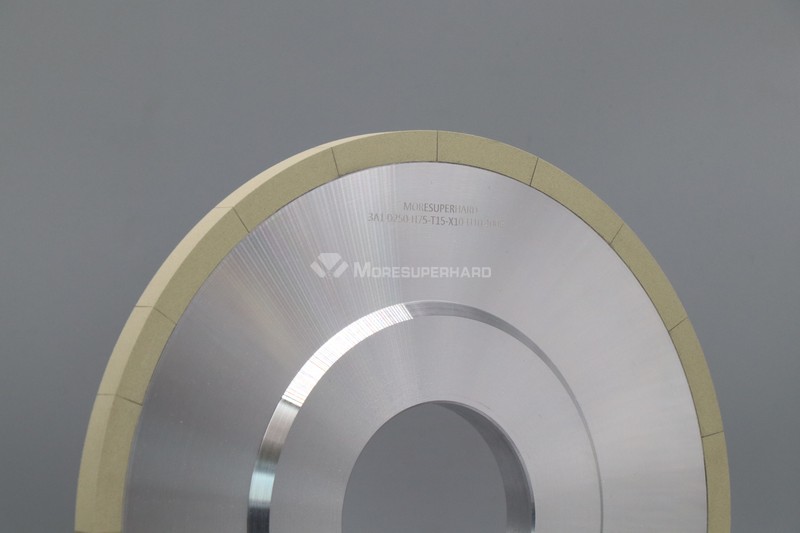

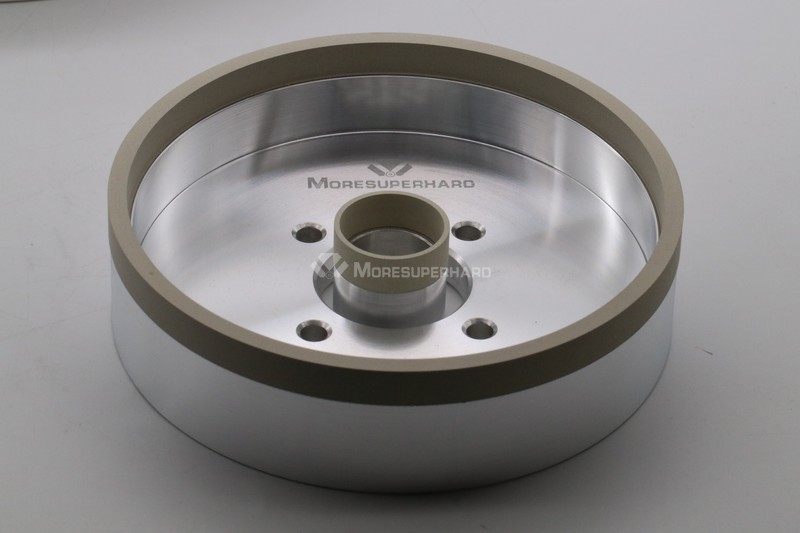

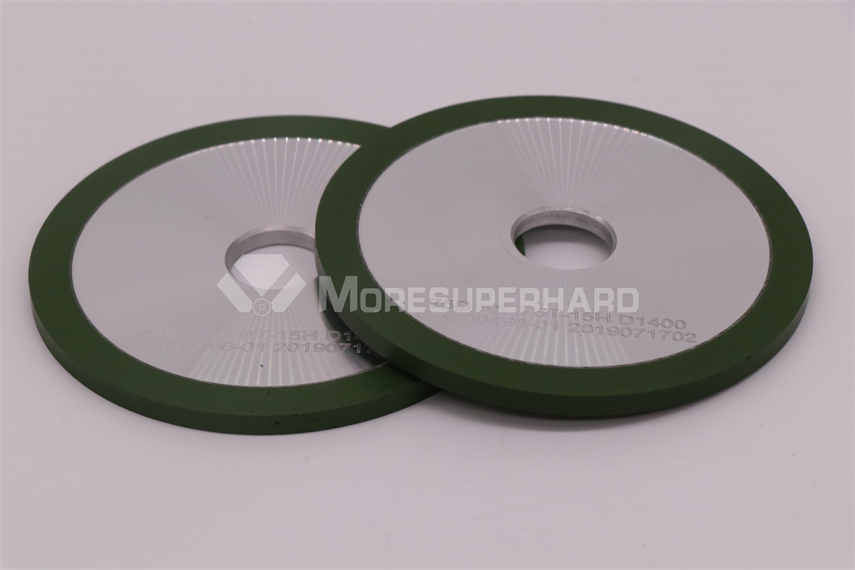

High Cermet grinding, vitrified diamond grinding wheels

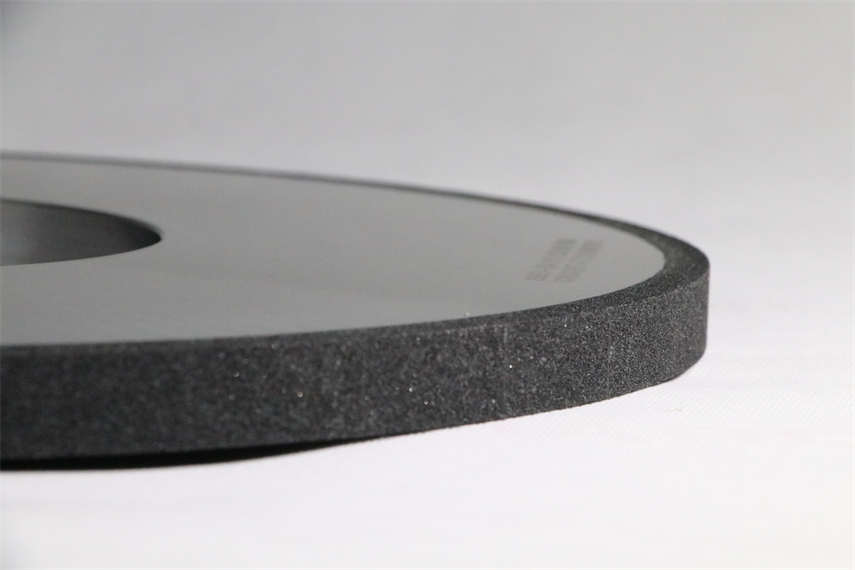

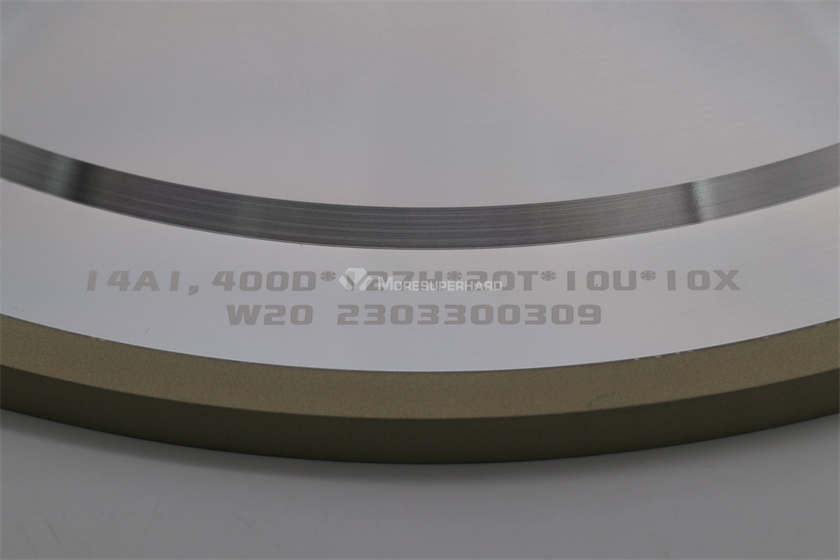

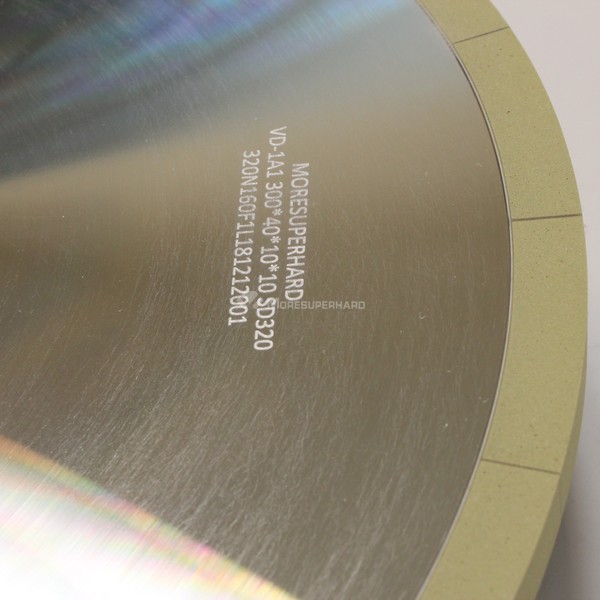

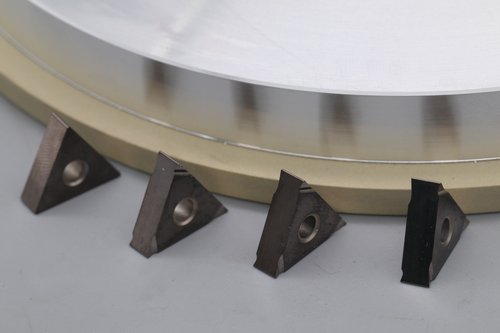

vitrified diamond grinding wheels mainly used for sharpening circular saw blades of cemented carbide, high-speed steel, cermet, PCD and pcbn, cvd, mcd, and band saw, etc

Contact US

Get Price

Share:

Content

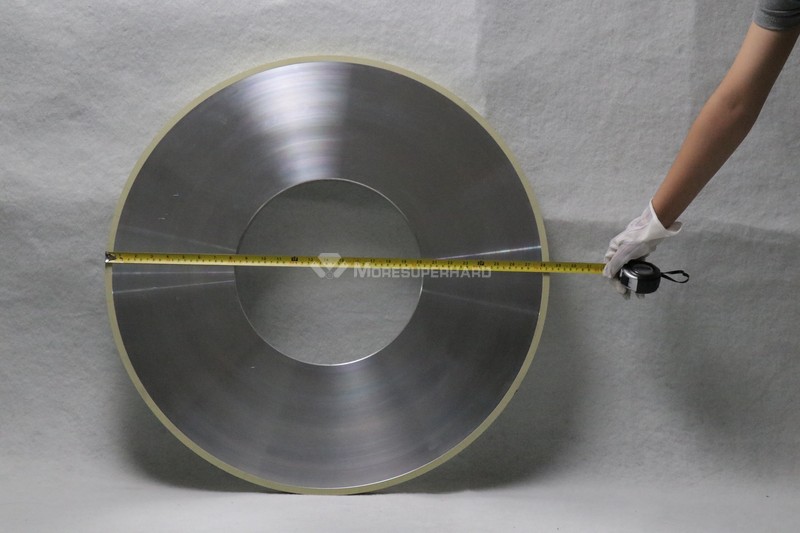

Vitrified diamond grinding wheels are mainly used for grinding.

PCD diamond tools, PCBN cubic boron nitride tools, polycrystalline diamond composites, sapphire/sapphire tools, diamond tools, tungsten carbide tools, ceramics, glass, crystals, gems, microcrystals , Wafer semiconductor silicon wafers, solar silicon wafers, rare earth materials, magnetic materials and other high-hard and brittle materials, and have achieved good economic benefits.

1. High durability and good shape retention: its durability is 2-3 times that of resin grinding wheels under the same grinding conditions. The grinding wheel has strong abrasive grain binding force, uniform and stable wear, and the shape of the grinding wheel is not easy to change;

2. Good sharpness: its grinding efficiency is about twice that of resin grinding wheels;

3. Good repairability: it has the same repairability as ordinary ceramic corundum and silicon carbide grinding wheels;

4. It is superior in the production of grinding wheels with a particle size of 0-5μm for superfinishing, which is the bottleneck of resin grinding wheels;

5. Compared with resin grinding wheel, the comprehensive cost of grinding process can be reduced by 20%-30%.

Inquiry

More Vitrified bond Diamond CBN Wheels