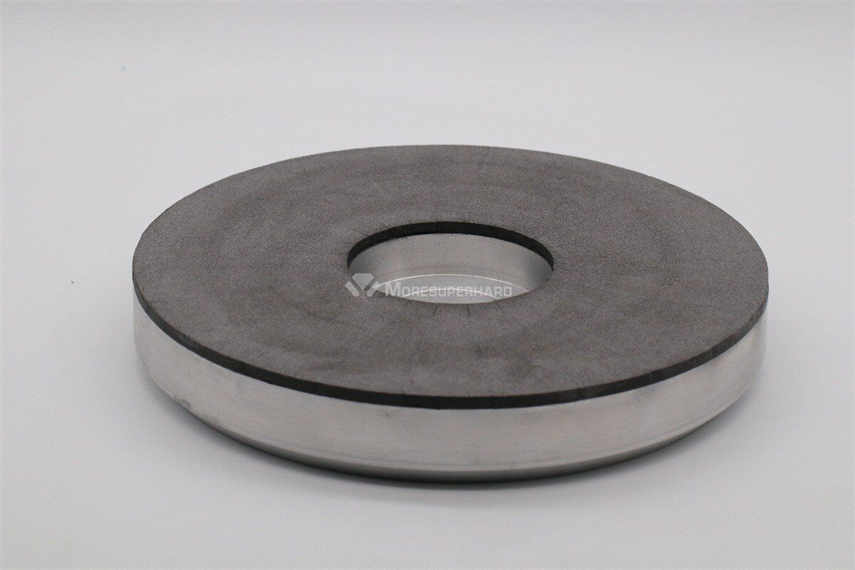

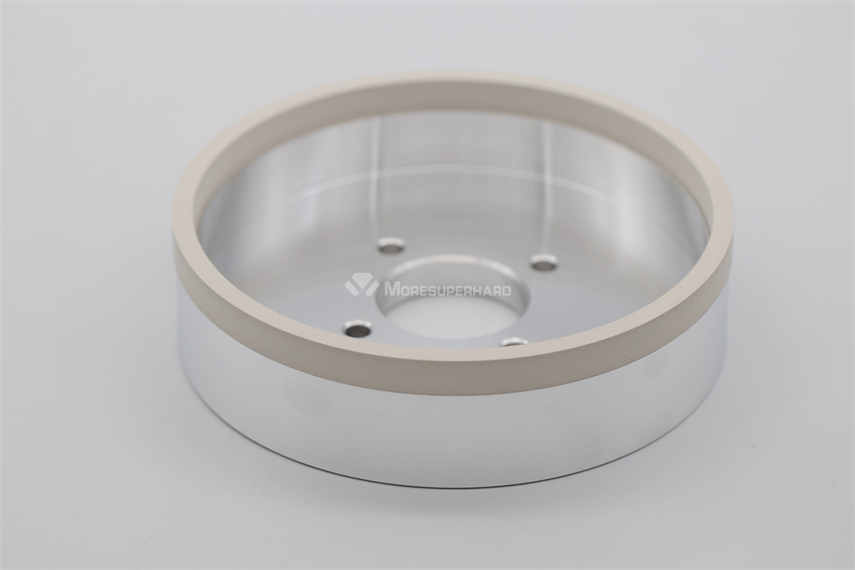

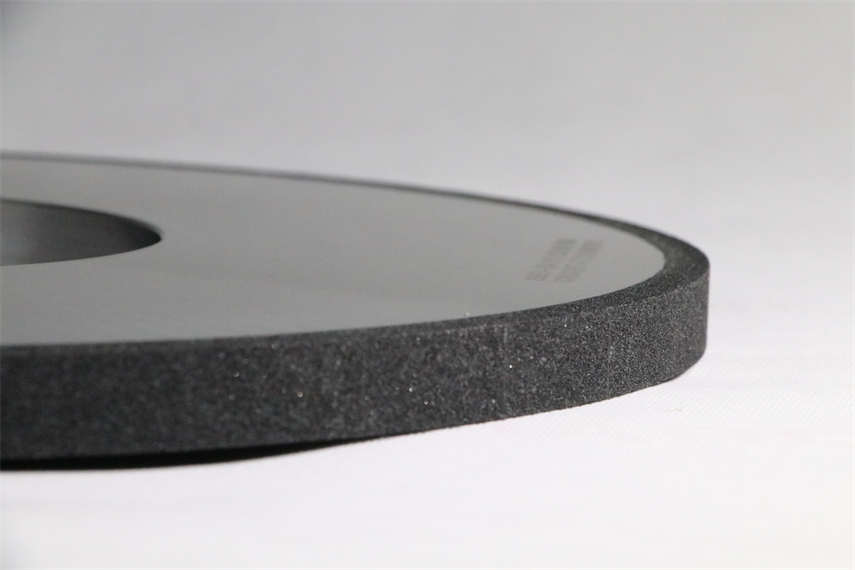

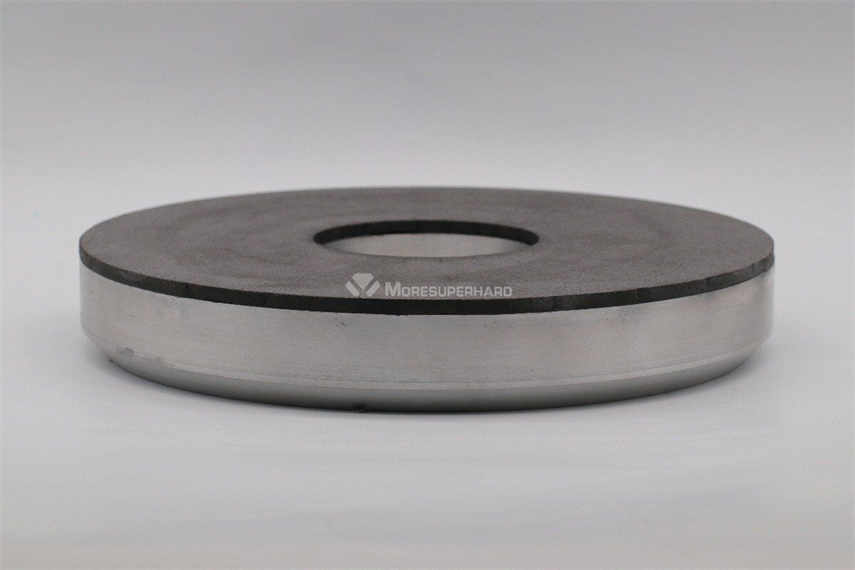

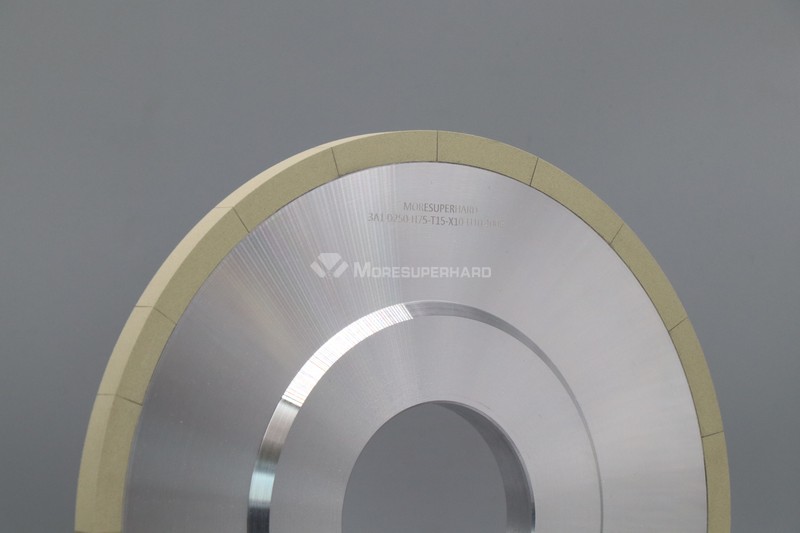

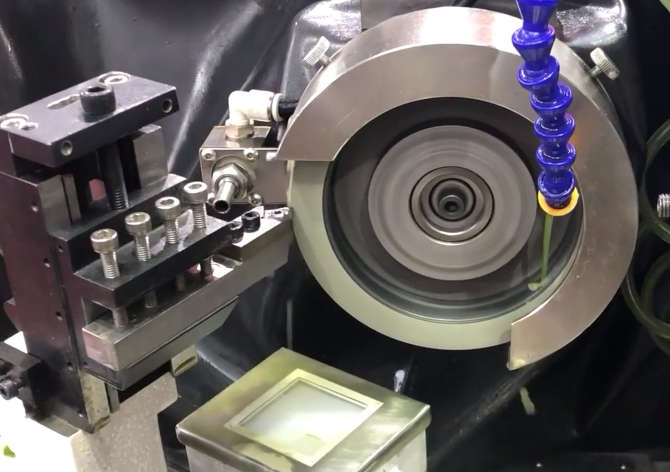

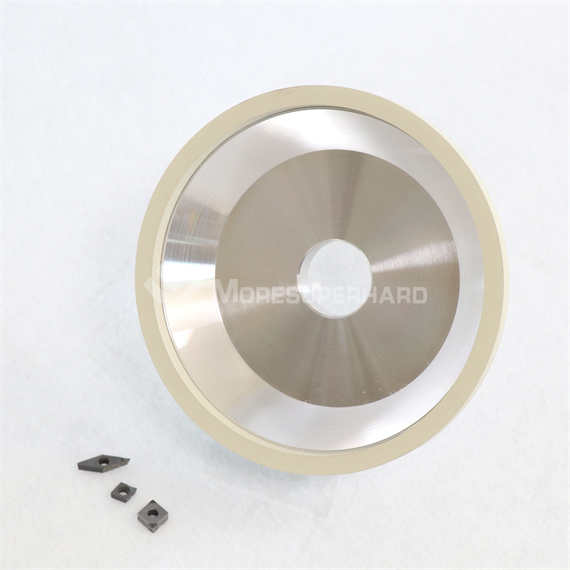

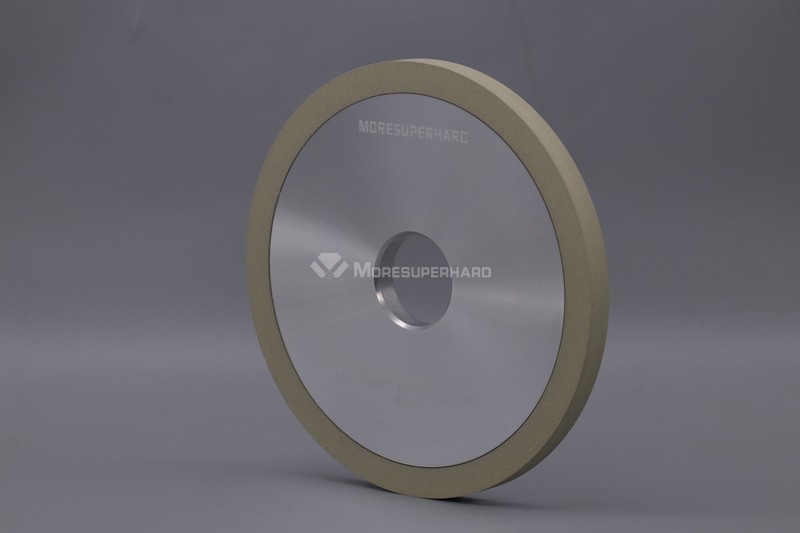

Vitrified diamond wheel for thermal spray coating

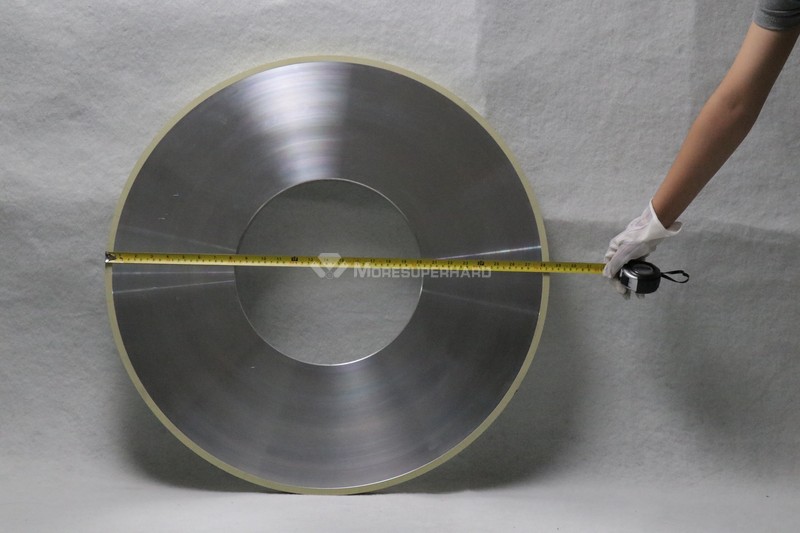

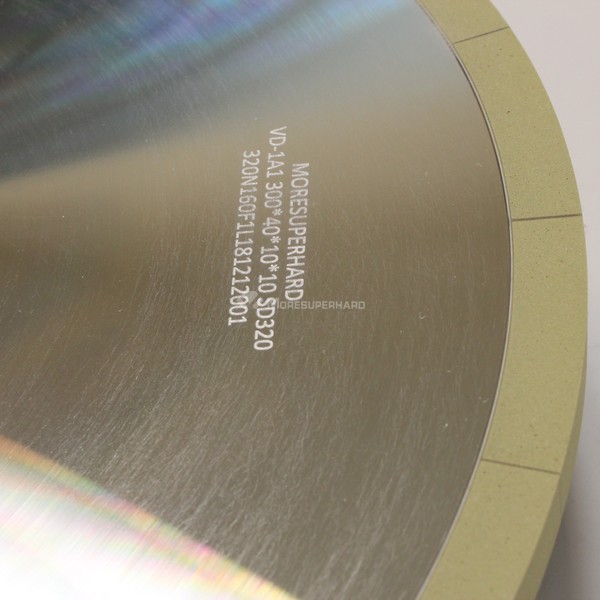

Vitrified diamond wheels are used for cylindrical grinding and finishing carbide coated rollers, printing roll, ceramics, wear parts and others hard coated materials. At present, our Vitrified diamond wheel can reach up to 28 inch ( 720 mm) diameter.

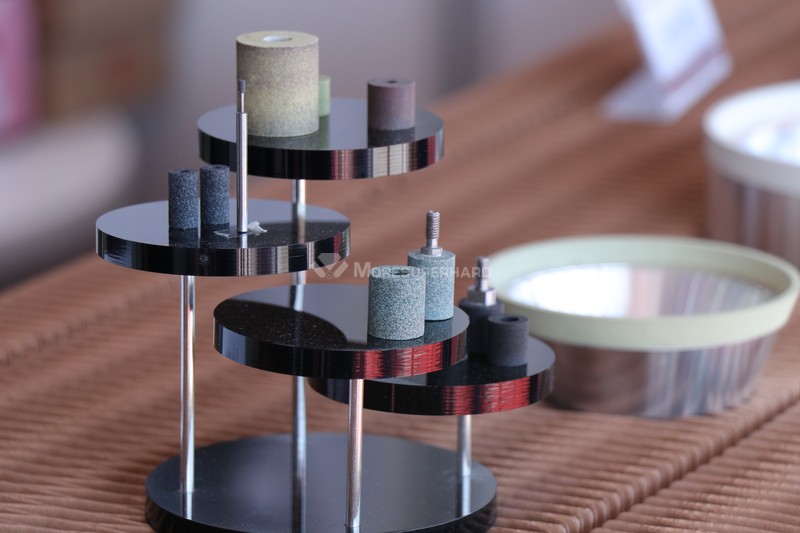

More SuperHard provides a full range of thermal spray coating solution and service which includes OD grinding, inside grinding, cylindrical grinding, surface grinding and polishing, etc. We have been present on the Thermal Spraying Coating industry for over 10 years . Our resin diamond wheels for HVOF carbide coating has enjoyed wide popularity in Canada, Turkey, Dubai, etc. Our products cover cylindrical resin diamond wheels , diamond internal grinding wheels and flexible diamond sand belts.

Thermal Spray Technologies Include

Flame spray (wire,rod,powder), Arc spray, Plasma spray (includes atmosphere controlled plasma spray), HVOF (high velocity oxygen and fuel spray) or HVAF(high velocity air and fuel spray), Detonation Spray, Cold spray.

Thermal spraying can provide thick coatings (thickness range from 20 microns to several mm), over a large area at high deposition rate as compared to other coating processes such as electroplating, physical and chemical vapor deposition.