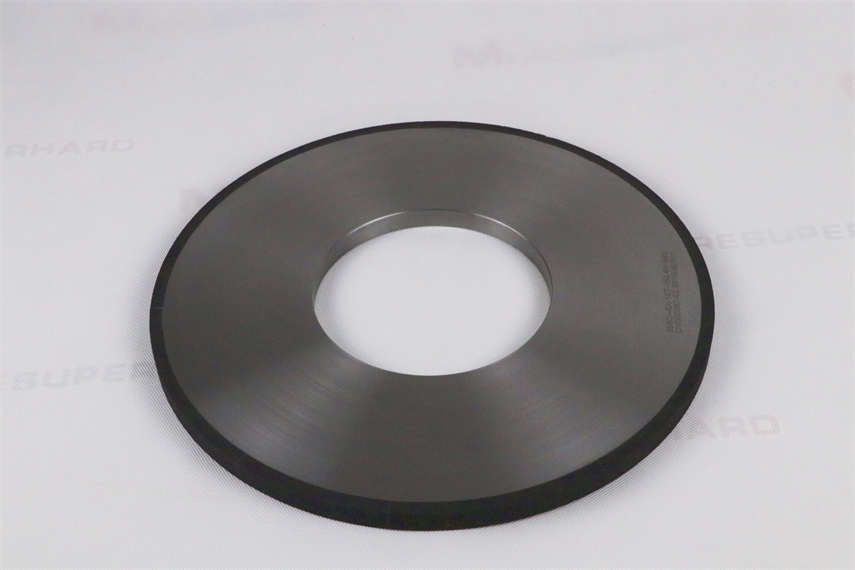

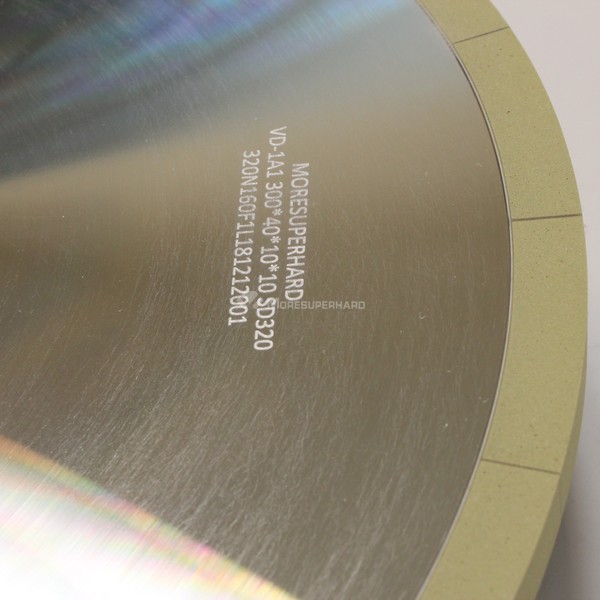

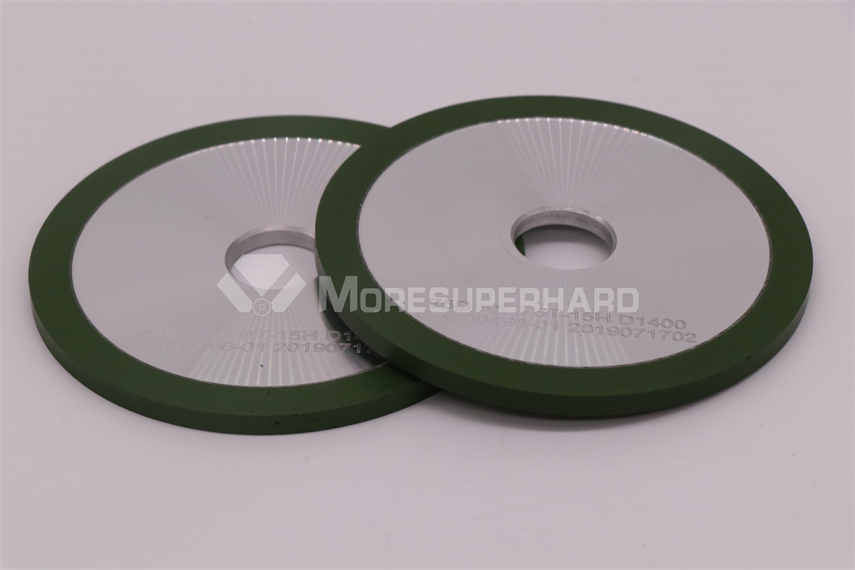

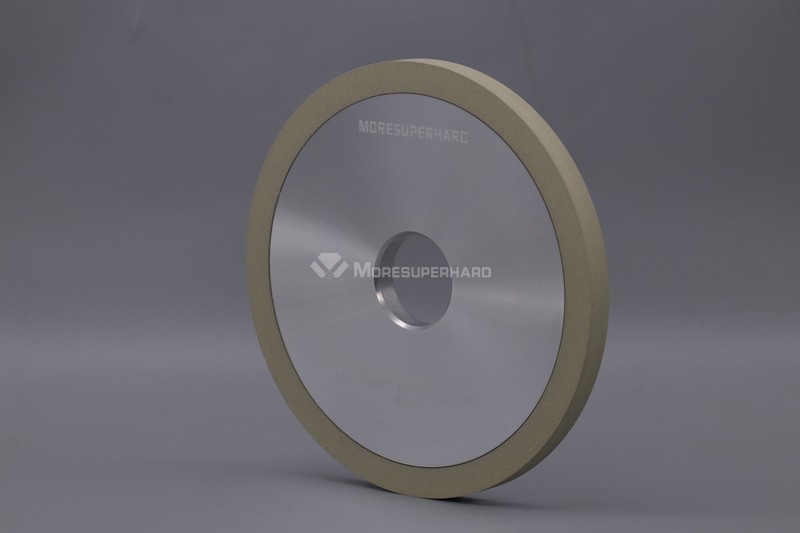

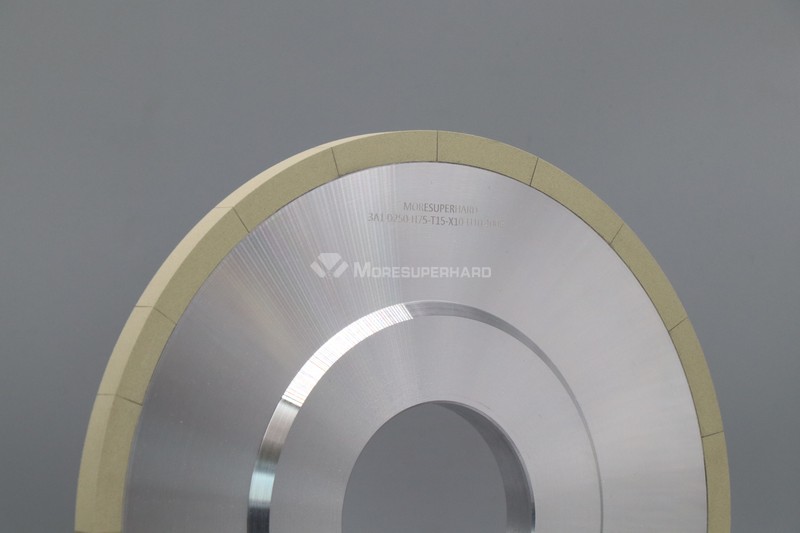

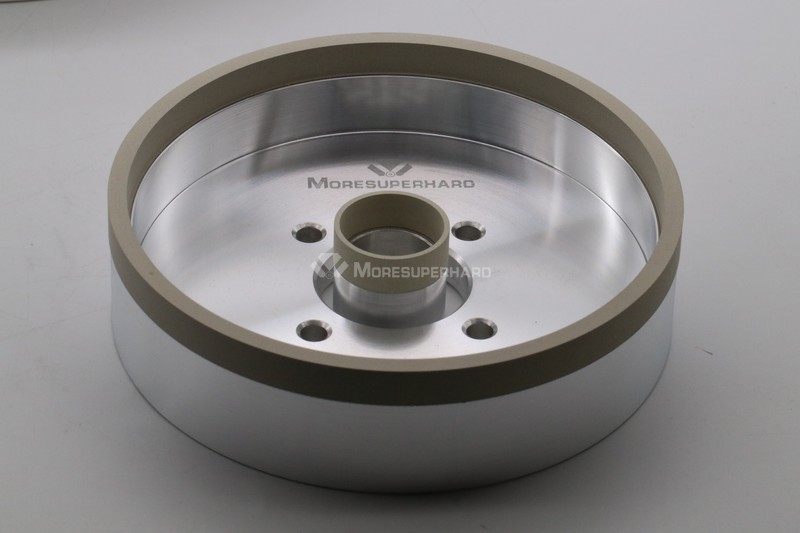

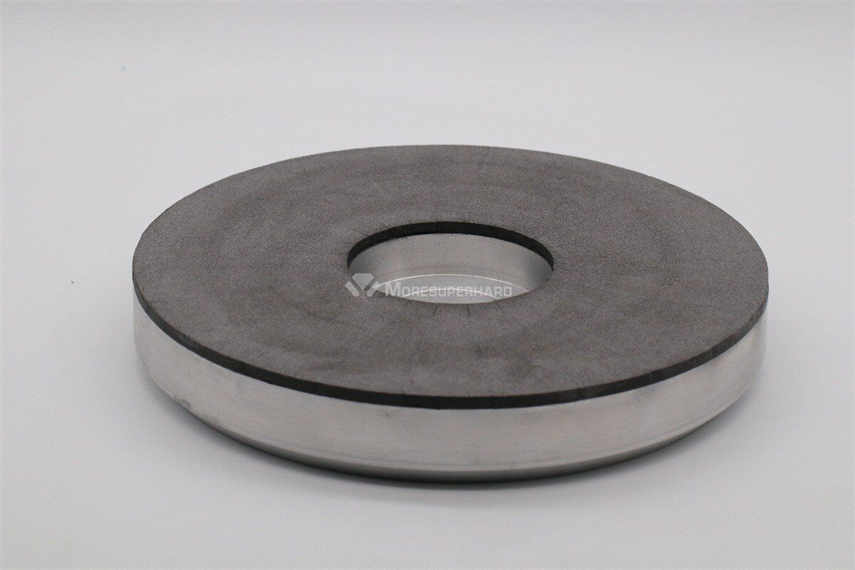

CBN internal grinding wheels vitrified bonded

CBN internal grinding wheels vitrified bonded suitable for grinding materials including

1. Cast iron: powder metallurgy, chilled cast iron, ductile cast iron, gray cast iron, alloy cast iron, etc

2. Steel parts: 20Cr, GCr15, Scr415H, 45 steel, 55 steel, etc

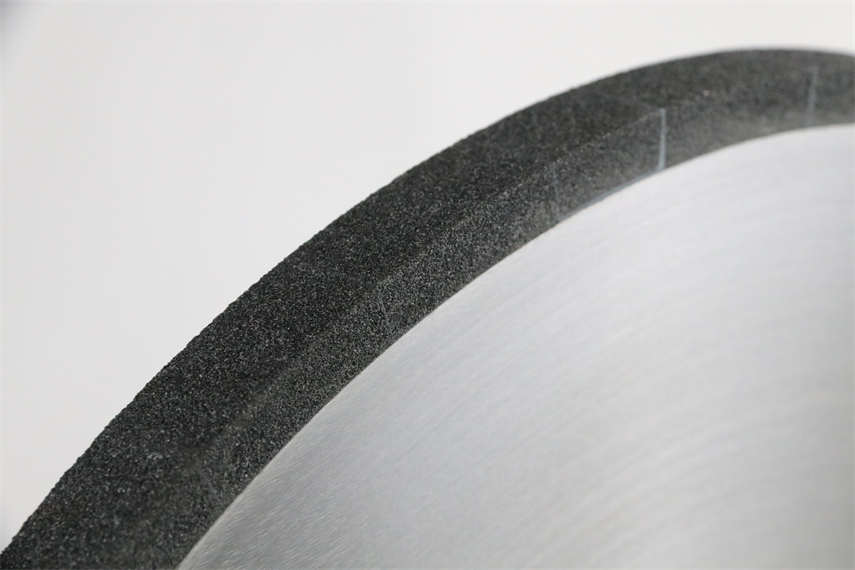

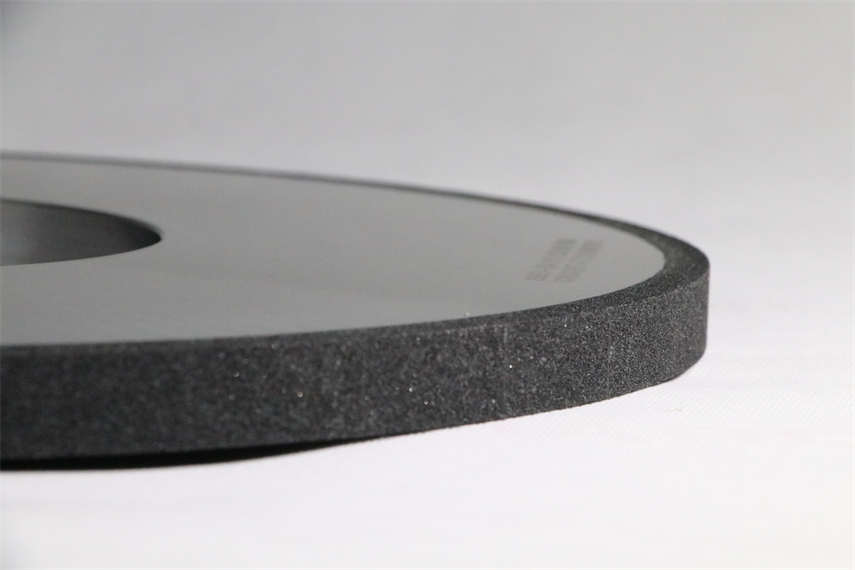

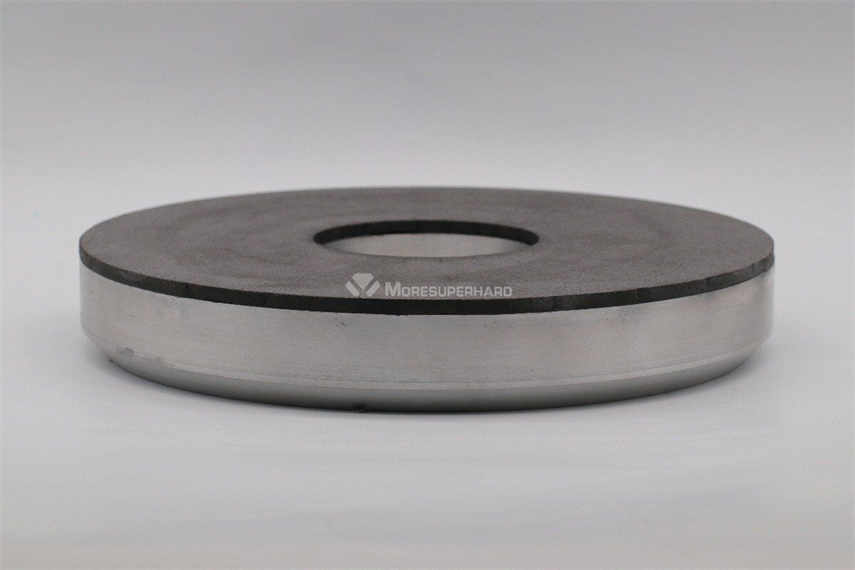

The vitrified CBN (cubic boron nitride) internal grinding wheel produced by our factory can achieve a small diameter of 1.5 mm, and the wear resistance is very good

CBN internal grinding wheels vitrified bonded

Processing HRC35-HRC70 degree steel parts (20 chromium steel, 40 chromium steel, tool steel, die steel, bearing steel, alloy steel, structural steel, high-speed steel, ductile iron, heat-resistant steel, titanium alloy, 38 chromium molybdenum aluminum, special Structural steel, etc.) Customized production of vitrified bond CBN internal grinding wheels and grinding heads for grinding small holes.

Parts with small holes within 5 mm in diameter require heat treatment or nitriding treatment before grinding to increase the hardness of the surface of the part, and enhance the wear resistance and compression resistance. According to different requirements, the hardness will be controlled between HRC35-HRC55 degrees, and there are also special requirements that the hardness will reach HRC70 degrees or more after treatment. CBN internal grinding wheels vitrified bonded deformation of the parts after heat treatment or nitriding (also ** is the amount of grinding) is generally between 0.10mm and 0.15mm.