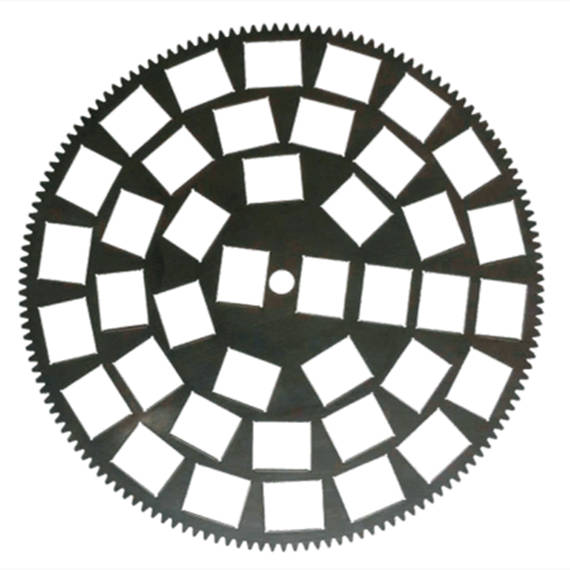

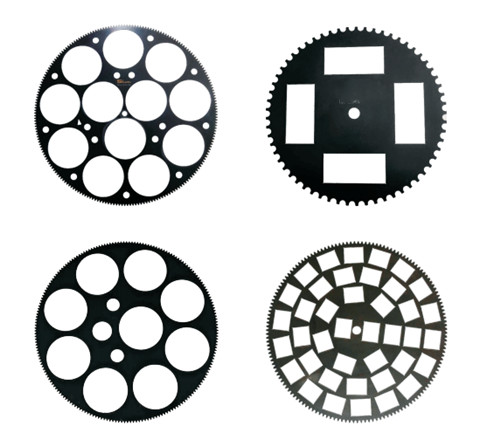

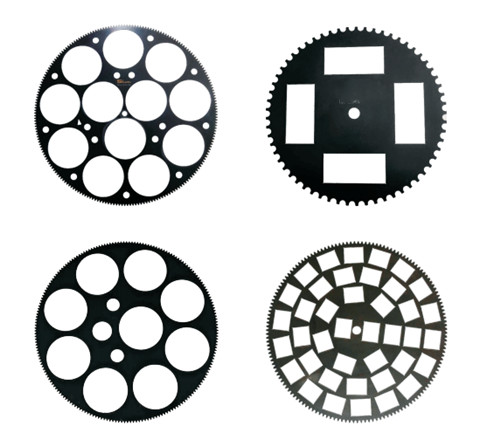

Blue Steel Planetary Wheel

Application:

Specialized carrier for grinding and polishing workpieces, mainly used in: semiconductor silicon wafers, Sic substrates, sapphire windows, sapphire, substrates, piezoelectric crystals, quartz crystal oscillators, optical glass and other materials for precision grinding and polishing.

Product features:

1. With independent core technology and mature process.

2. It is not easy to deform:Adopting unique heat treatment process, it fully releases the internal stress of the material, so it is not easy to deform in the process of using.

3. Good flatness:Warping degree <30%, no running piece.

4. Strong abrasion resistance: Take the actual work of 16B touring wheel as an example, continuous work 8500 rpm, the surface wear is only 0.02mm, and the surface Vickers hardness of the product reaches above HV370.

5. Good smoothness: the surface flatness of the product is 0.005-0.01mm, the circumferential precision is t0.02mm, the work is smooth, no micro-vibration, which improves the rate of finished products.

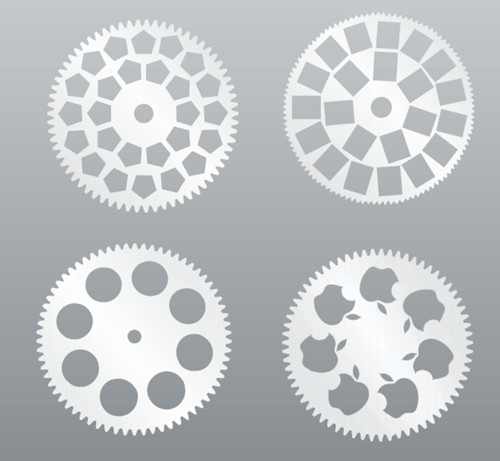

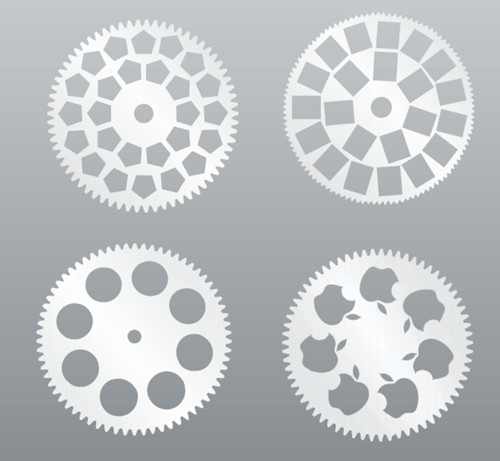

Stainless Steel Planetary Wheel

Application

Specialized carrier for grinding and polishing workpieces, mainly used in: semiconductor silicon wafers, Sic substrates, sapphire windows, sapphire substrates, piezoelectric crystals, quartz crystal oscillators, optical glass and other materials for precision grinding and polishing.

Product Features

Advantages: Stainless steel material has good corrosion resistance to acid and alkali, suitable for products containing acid and alkali process in the grinding and polishing process.

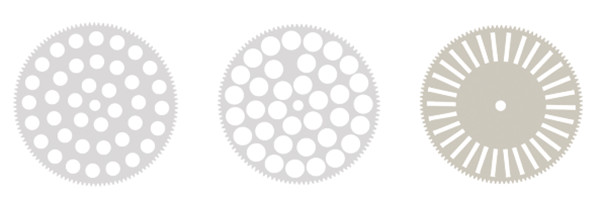

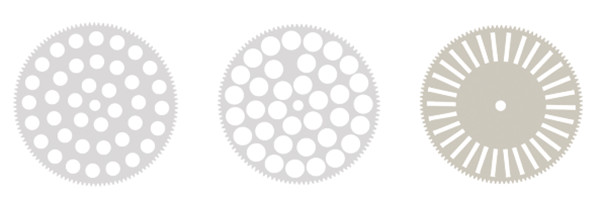

Epoxy Board Planetary Wheel

Application

Grinding and polishing workpiece carrier, mainly used in: semiconductor silicon wafers, Sic substrate, sapphire window, sapphire substrate, piezoelectric crystal quartz crystal oscillator, optical glass and other materials for precision grinding and polishing.

Product Features

Advantages: 1. Good smoothness, flatness, parallelism can be controlled in a strict range of accuracy.

2. The contact surface on the side of the workpiece will not produce defects such as chipping point and bright spot.

Disadvantages.

1. Short service life.

2. The sheet can not be used normally because of the lack of strength of the material.