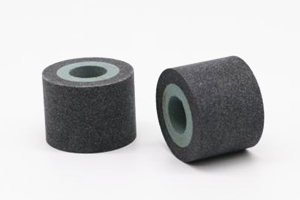

What is the ceramic CBN internal grinding wheel?

Ceramic CBN internal grinding wheels are made of cubic boron nitride abrasives and sintered with metal powder, resin powder and ceramic as a bonding agent to form various shapes of abrasives for industrial grinding, polishing and lapping. This kind of ceramic internal grinding wheel maintains the original high hardness performance of ceramic grinding wheel, low sintering temperature, high strength and toughness, good abrasive holding performance, and has the characteristics of heat resistance, oil resistance, water resistance, acid and alkali resistance, good self-sharpening, dressable and long dressing interval. Uniform porosity for easy cooling, chip removal, etc. It does not block or burn the workpiece in the grinding process, does not cause chemical changes with the Iron group elements, shows its inertia, reduces the fatigue of the workpiece in the grinding process (ID/OD grinding), increases the service life of the workpiece, thus improving the quality, roughness and efficiency of the processed workpiece as well as the automation of the processed workpiece, and achieving the purpose of reducing the comprehensive cost.

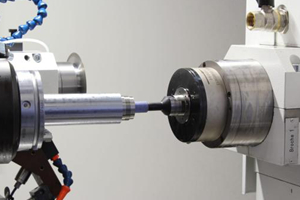

What are ceramic internal grinding wheels used for?

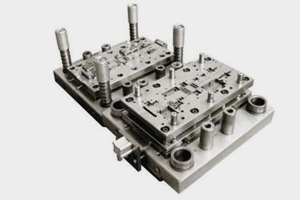

Grinding of Con-rods ends in the Auto Industry .

Grinding of Hydraulic and Pneumatic Cylinders .

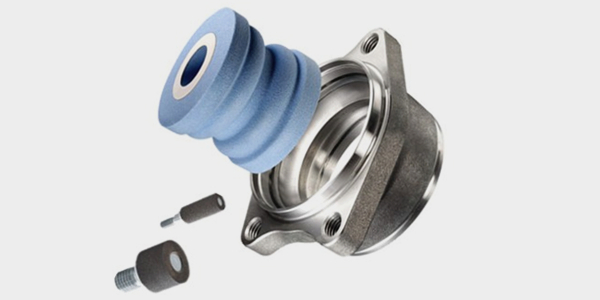

CVJ ball-cage, inner and outer raceway .

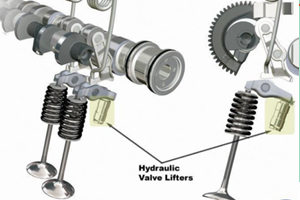

Hydraulic tappet of automobile motor .

Grinding of Bores of Inner Rings .

Grinding of Gears Bores, Collects.

Pump stator of automobile,Grinding of Gun Barrels .

Roller, cylinder, flange cover of air-condition compressor.

Grinding of Inner and outer faces of Ball & Roller Bearings.

.jpg)

.jpg)

.jpg)