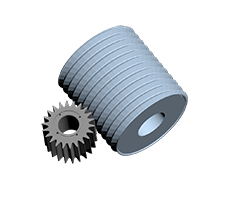

High precision dressing tools are essential for accurate profiling and sharpening of grinding worms and honing rings. They determine the quality of the finished gears. A dresser for molding tooth shape of warm-shaped general whetstones used for grinding gear. Precision electrodeposition technology, high accuracy grinding surface truing technology and our original tooth shape design technology allow for stably maintaining high tooth shape precision, contributing to the reduction of gear grinding process cost.

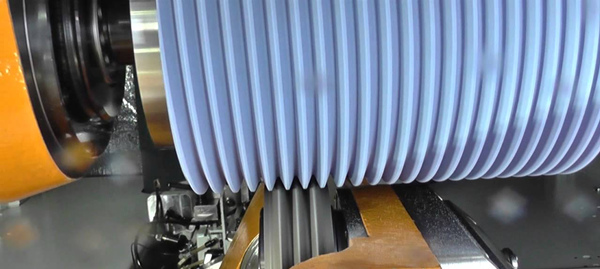

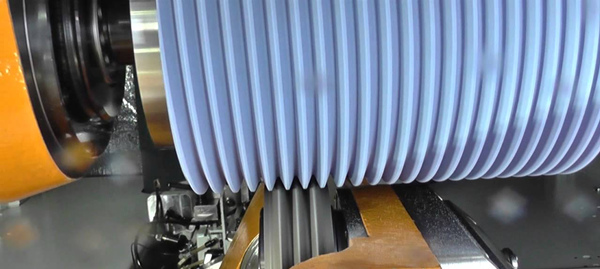

Single-taper dressing wheels

Single-taper dressing wheels

• Excellent, highly versatile tool design

• Dressing wheels are used in pairs, each with its own powered dressing spindle

• Dressing wheels can be independently angled and the optimum positioning of the dressing tools guarantees the highest gear quality

• The pitch of the grinding worm can be adjusted by changing the distance between the dressing wheels

• The profile depth of the grinding worm can be individually selected

• Can be used across different modules, if required

• Tooth root grinding can be integrated using additional design features

• Tools can be regenerated by regrinding or replating the body

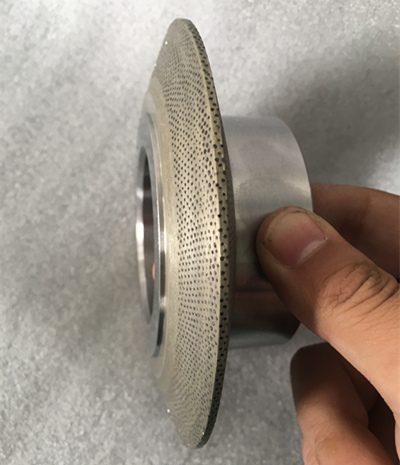

Profile roller dressers

• An excellent tool design with low setup requirements

• Particularly suitable for module ranges

• The full profile roller dresser is basically used as an individual tool on a powered dressing spindle

• For single-pass and multi-pass dressing

• The design of each tool is specific to that of the workpiece

• Tooth root grinding is normally used

• Tools cannot be regenerated by regrinding or replating the body

.png)

.jpg)

.jpg)

_.jpg)

.png)