Abrasive grinding wheels for steel ball manufacturing are available in both

vitrified and resin bond types.

Applications of abrasive vitrified bond/ resin bond grinding wheel

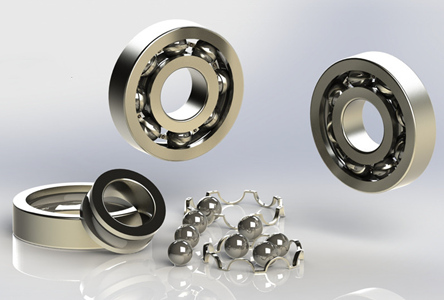

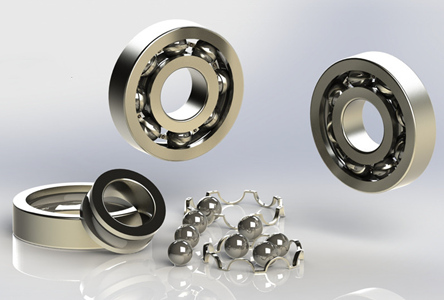

Suitable for all kinds of bearing steel ball, carbon steel, stainless steel balls grinding

_.jpg)

Vitrifie bond Grinding Wheel - steel ball grinding

Vitrifie bond Grinding Wheel - steel ball grinding

Rough grinding operations which are carried out by vitrified wheels to remove large amounts of material. Grinding wheels for steel ball are the current annual production capacity is more than 1000 pieces of various specifications.

_.jpg) Advantages of vitrified bond grinding wheels for steel ball grinding

Advantages of vitrified bond grinding wheels for steel ball grinding

♦ High density and high hardness grinding wheels are used for hard grinding process of steel balls, with even and fine structure, high grinding efficiency, good durability characteristics, etc.

♦ Steel balls ground by vitrified grinding wheels are with low surface roughness, good roundness and high precision

♦ Brittleness and moderate toughness, It is good for grinding steel ball ‘s surface roughness and geometry precision.

♦ Trimming easily, and not to be collapsed easily

Resin bond Grinding Wheel - steel ball grinding

Resin bond grinding wheels for steel ball are used for precision grinding of bearing steel ball to provide a good surface finish

_.jpg) Advantages of resin bond grinding wheels for steel ball grinding

Advantages of resin bond grinding wheels for steel ball grinding

♦ High grinding efficiency, high precision and good surface quality for steel ball processing, low vibration value

♦ Reducing grinding time, low cost,

♦ The special grinding fluid is good for environmental protection , reducing environment pollution, easy to clean

_.jpg)

_.jpg)

_.jpg)

_.jpg)

_.jpg)