Moresuperhard's grinding products for DANOBAT Vertical grinding machines:

Moresuperhard Resin/Virified CBN Grinding Wheels:

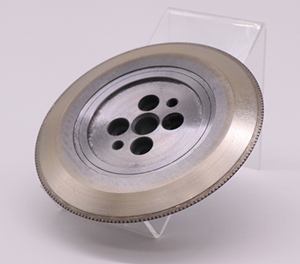

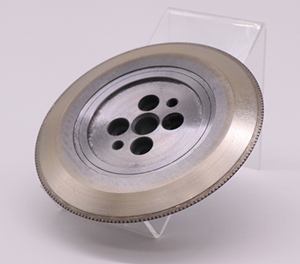

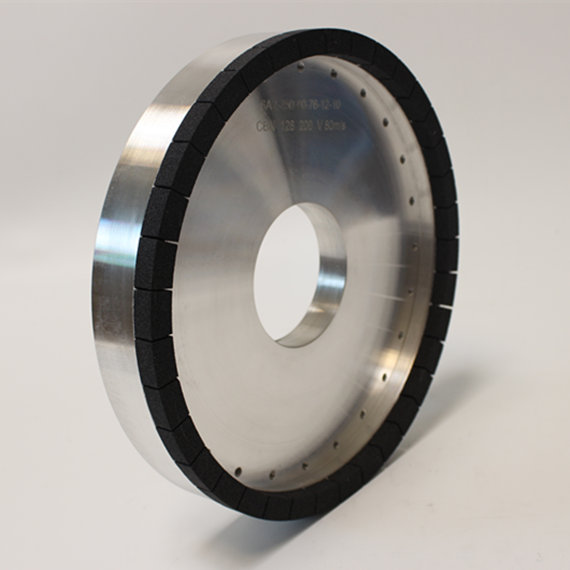

Moresuperhard Resin CBN Grinding Wheels:

Moresuperhard Resin CBN Grinding Wheels:

Resin CBN grinding wheels are suitable for grinding workpieces such as hardened steel, high-speed steel, cast iron, stainless steel and nitrided stainless steel.

At the same time, in order to improve production efficiency, people began to use CBN grinding wheels on low-speed grinding machines to increasingly replace ordinary grinding tools.

Features of Resin CBN grinding wheels:

►Excellent Grinding Action

►less apt to experience loading

►dressing easily for added convenience

►Convenience and Ease of Use

At present, resin CBN grinding wheels are widely used for precision grinding of workpieces containing iron group elements in industries or fields such as automotive, bearings, compressors and precision molds, and have become an irreplaceable tool in manufacturing production and grinding processing.

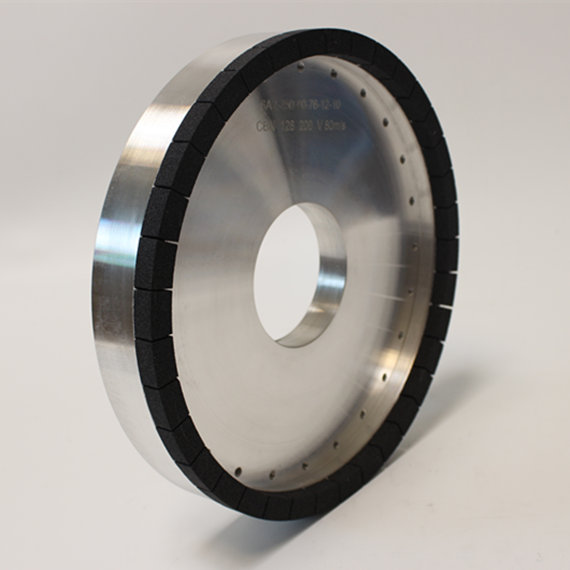

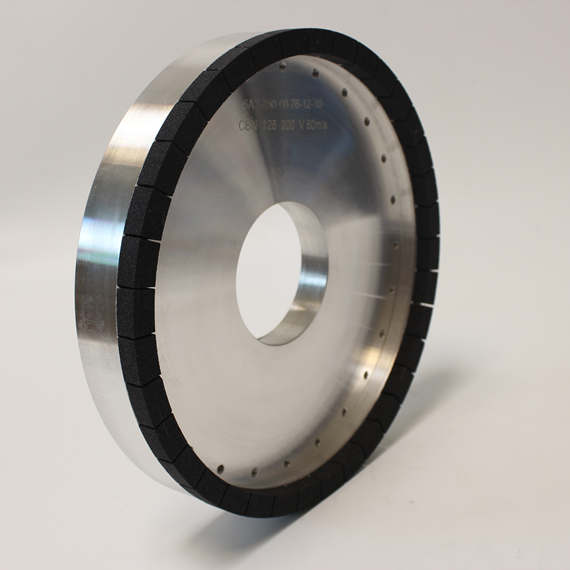

Moresuperhard Vitrified CBN Grinding Wheels:

Vitrified bond CBN Grinding Wheel is suitable for high-efficient heavy grinding of a camshaft of automobile parts. The wheel speed is 80m/s-160m/s, designed to be used on CNC Cam Grinders like Toyoda, Schaudt, Landis, Junker, etc.

Applications: inner grinding of bearing, compressor, CVJ ball-cage, hydraulic tappets, universal joint, stator and rotor.

Moresuperhard's vitrified CBN grinding tools with highest grinding layer for extended wheel life on the machine. Due to the special manufacturing process very high grinding layers on wheels are possible to shorten the setup-costs in the grinding process.

Features of vitrified CBN grinding wheels:

► longer wheel life

► shorter grinding cycle times

► automated grinding production capabilities with wheels dressed right on the grinder

Vitrified CBN products are ideal for steel and ferrous alloy grinding applications in automotive, aerospace, medical, production tooling, etc. They are excellent thermal conductors and do not react with ferrous materials during the grinding process like diamond does.

Moresuperhard's Conventional Grinding Wheels:

.jpg)

If the diamond or Cbn Grinding Wheels become dull and the efficiency lower, they can be corrected by dressing or truing of the Diamond or CBN grinding wheels.

Dressing is the process of breaking away the glazed surface so that sharp particles are again presented to the work. The common types of wheel dressers known as [dressing Grinding Wheel" - Green carbon grinding wheel o

r white corundum are used for this purpose. The dressing grinding wheel is held against the face of the revolving wheel and moved across the face to dress the diamond or CBN Grinding Wheel surface.

SG conventional grinding wheels:

► SG abrasive grinding wheel for gear industry

► Aluminum oxide grinding wheel

► 5-10 Times than the grinding wheel made of common corundum

► Very good cutting capability, sharp grains

Applications of SG grinding wheel

► Precision grinding for unhardened and hardened steels,such as cast iron,carbon steels, alloy steels, and tool steels, etc

► Internal grinding roller bearings, cylinders, compressor parts,gear parts, hydraulic and pneumatic cylinders etc

► Grinding the crankshaft and camshaft of the engine and transmission of the car, worm gear grinding

Diamond Dressing Tools, Diamond Stationary Dressers

Diamond Dressers are made with natural diamond and synthetic materials. For truing and dressing of conventional abrasive grinding wheels.

Application: large OD wheels, surface and centerless grinding wheels. It is used for auto parts, mould industry and other precision machinery parts industry

► Single point diamond dressers

► Multi point diamond dressers

► Forming diamond dressers

► Impregnated diamond dressers

.jpg)

.jpg)