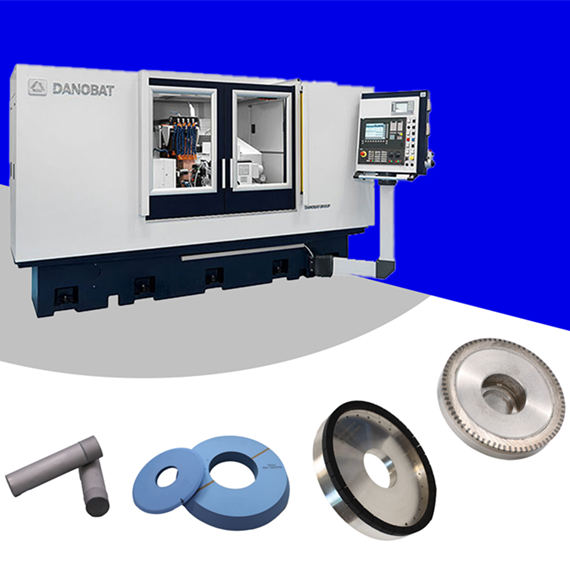

| DANOBTAT grinding |

DANOBTAT grinding machine model |

Grinding machine features |

Moresuperhard Grinding Products for DANOBAT |

Application |

| Cylindrical grinding |

CG/PG cylindrical grinding machine |

Grinding wheel diameter: Max. 910 mm X 350 mm |

Ceramic CBN wheel (also available in resin) |

It can be used for external and end grinding of constant velocity shaft, transmission shaft, steering gear shaft, etc. It can also be equipped with internal and external grinding spindles for internal grinding, external grinding and polishing grinding. |

| (High capacity grinding machine) |

Workpiece outer diameter: Max. 440 mm |

SG grinding wheel |

| |

Number of grinding spindles: up to 3 |

Ordinary grinding corundum grinding wheel |

| |

|

Trimming pen trimmer, trimming roller |

| LG cylindrical grinding machine |

Linear speed of grinding wheel: Max. 140 m/s |

Ordinary grinding corundum grinding wheel; |

It is used for the grinding of high-precision complex workpieces of cutting tools, hydraulic parts and automotive precision parts, and is also suitable for the grinding of camshafts or other eccentric workpieces. |

| (High precision grinding machine) |

Workpiece length: Max. 1000 mm |

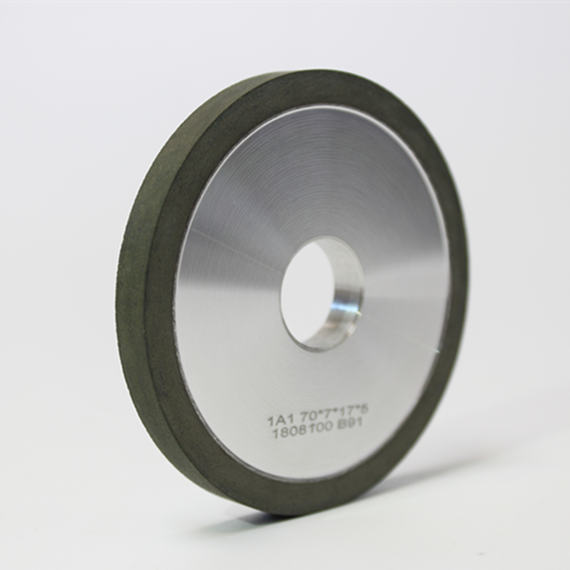

Resin CBN grinding wheel |

| |

|

Ceramic CBN high speed grinding wheel |

| |

|

SG grinding wheel |

| |

|

Trimming pen trimmer, trimming roller |

| HG cylindrical grinding machine |

Workpiece length: Max. 5000 mm |

Corundum grinding wheel, |

Can be used for grinding the excircle, the inner circle, the end face and the conical surface of transmission shafts, motor shafts, gas turbine and aero-engine rotor shafts, fan gear shafts, turbine shafts, railway axles, machine tool spindles and large gear shaft |

| (Universal Heavy Grinding Machine with Moving Table) |

Workpiece outer diameter: Max. 1040 mm |

SG grinding wheel |

| |

Wheel diameter: Max. 1060 mm |

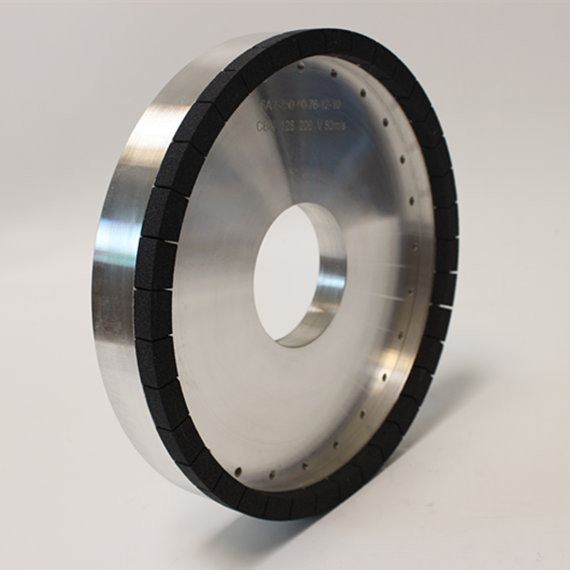

Diamond grinding wheels, |

| |

|

Ceramic CBN grinding wheel |

| |

|

Electroplated CBN grinding wheel |

| |

|

Worm grinding wheel |

| |

|

Trimming pen trimmer, trimming roller |

| WT cylindrical grinding machine |

Workpiece length: up to 10000 mm |

Corundum grinding wheel, |

It is applied to the cylindrical grinding of giant slalom diameter workpieces such as rear shaft, main shaft, landing gear, power shaft, turbine rotor, railway axle, etc. |

| (Grinding carriage mobile universal heavy duty grinding machine) |

Workpiece outer diameter: Max. 1000 mm |

SG grinding wheel |

| |

Grinding wheel diameter: Max. 1220 mm |

Diamond grinding wheel, CBN grinding wheel |

| |

|

Trimming pen trimmer, trimming roller |

| MBTG-DANTIP Cylindrical Grinder |

Blade tip grinders can be combined with Danobart vertical grinders to form a "matching grinding unit", which constitutes a complete solution for the matching processing and measurement of the rotor and shell of the same engine. |

Microcrystalline ceramic corundum grinding wheel |

|

| (Rotor blade tip grinding and measurement) |

SG grinding wheel |

|

| |

Electroplated CBN grinding wheel |

For high-precision grinding, deburring and measuring of rotor blade tips |

| |

Trim the pen |

|

| |

Finisher |

|

| |

Trim the roller |

|

| DANUNI cylindrical grinding machine |

Workpiece length: Max. 3750 mm |

SG grinding wheel |

It is used for precision grinding of various landing gear components, and can perform high-precision external and internal grinding, such as the internal and external diameters of complex struts and piston rods. |

| (High precision grinding machine for aircraft landing gear) |

Wheel diameter: Max. Ø915 mm X 75 mm |

Corundum |

| |

Maximum workpiece rotation range: 6500 mm |

CBN grinding wheel (electroplated) |

| |

|

Trimming pen trimmer, trimming roller |

| Internal grinding |

ID-Internal Grinder |

Workpiece length: up to 400 mm |

Internal grinding head |

Can be used for gear workpieces, cutting tools, bearings, non-circular workpieces and hydraulic parts of the outer circle, the inner circle and face grinding, suitable for single manufacturing and mass production, the whole system uses linear motor drive, especially suitable for non-circular grinding |

| (Internal and external grinding machine) |

Workpiece turning diameter: up to 400 mm |

Internal grinding wheel |

| |

Maximum number of grinding spindles: 4 |

(Various binders) |

| |

|

Supporting trimmer and trimming wheel |

| IRD-Internal Grinding Machine |

Workpiece inner diameter: Max. 200 mm |

Internal grinding head |

It can be used for inner circle, outer circle, arc, end face and non-circular grinding. |

| (Internal and external circular and circular arc grinding machine) |

Workpiece length: up to 400 mm |

Internal grinding wheel |

| |

Maximum number of grinding spindles: 4 |

(Various binders) |

| |

|

Supporting trimmer and trimming wheel |

| ILD-Internal Grinding Machine |

Workpiece turning diameter: Max. 760 mm |

Internal grinding head of conventional grinding machine |

It can be used for grinding internal and external circles, conical surfaces and fillets. |

| (Internal grinding of long workpieces) |

Workpiece length: up to 1300 mm |

Ceramic CBN internal grinding head |

| |

Grinding bore length: 400 mm |

Diamond, CBN internal grinding head |

| |

|

(Various binders) |

| |

|

Trimming pen trimmer, trimming roller |

| |

|

|

| IED-Internal Grinder |

Maximum number of grinding spindles: 5 |

Internal grinding head of conventional grinding machine |

|

| (Internal and external synchronous grinding) |

Grinding wheel diameter: Max. 500 mm |

Ceramic CBN internal grinding head |

| |

|

Diamond, CBN internal grinding head |

| |

|

(Various binders) |

| |

|

Trimming pen trimmer, trimming roller |

.jpg)

.jpg)