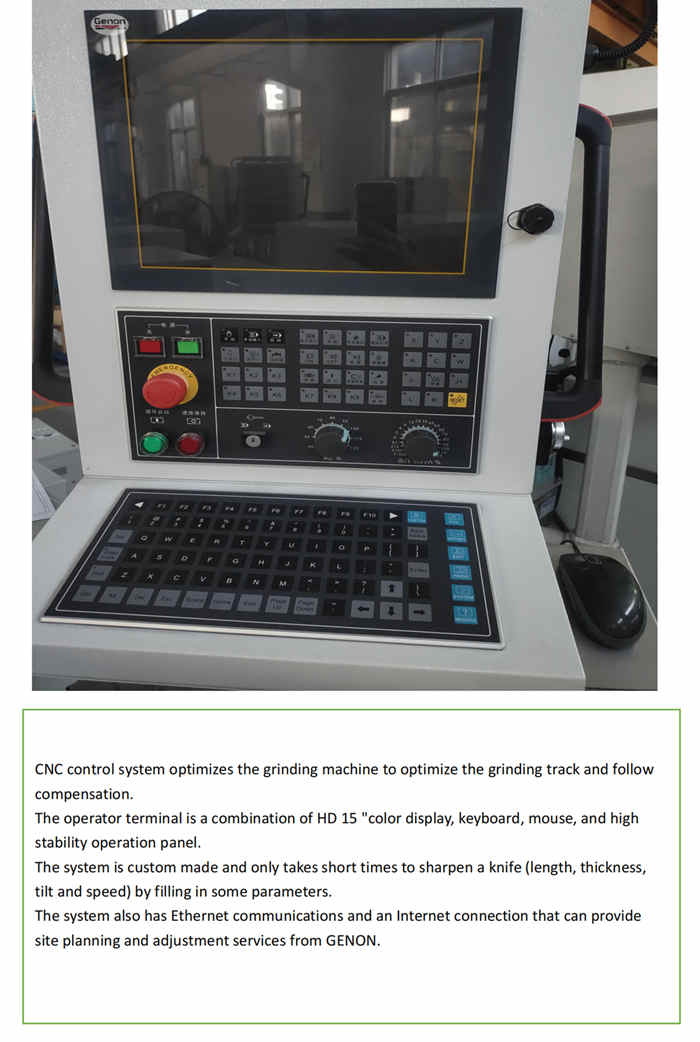

with ability of bolster dressing.

2 set Graphic grinding software

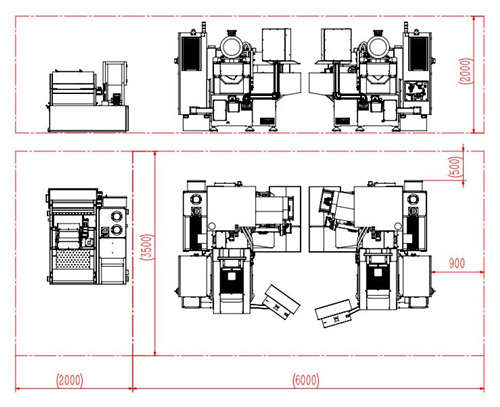

Mechanical structure of Knife Blade Grinding Machine:

The machine base is Integral forming of die casting

A set of flat grinding machine are respectively composed of left and right side grinders

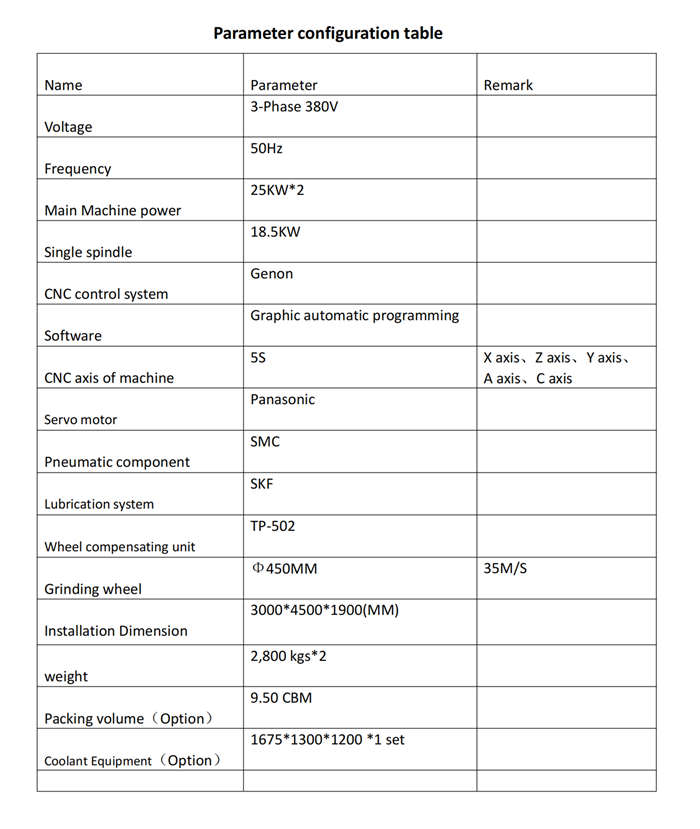

Each structure has five servo axis, which are:

X axis = main feed axis of the grinding table

Z axis = infeed axis for grinding wheel

Y axis = vertical axis

A axis = tilt axis/grinding angle

C axis = C axis for work-piece carrier rotating axle.

SURFACE FINISHING:

Base paint by means of anti-rust epoxy primer coating.

Color : Base - grey (7011) , Body - blue (5019), Control Cabinet - grey white (9002)

(other colors available with extra cost)

Maximum grinding length 390 mm

Work-piece carrier feed speed for no grinding movements: 30m/min

Work-piece carrier feed speed for grinding movements: between 0 and 10 meters per

minute.

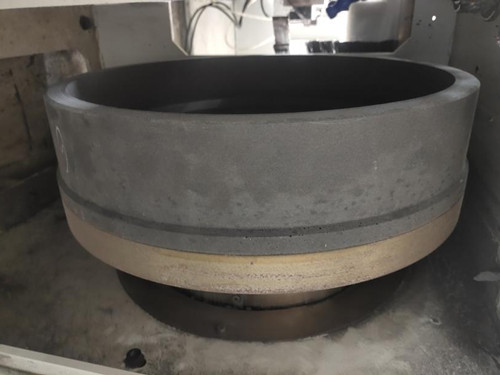

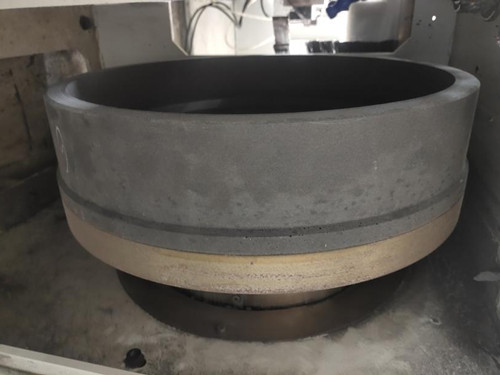

Grinding wheel structure of Knife Blade Grinding Machine:

1.The machine is equipped with 1 grinding wheel holder

spindle, which is activated by means of drive belts and

pulleys.Grinding drive power 18.5KW (26 HP) each side.

2. The diameter of the receiving flange for grinding

wheel is 450mm.

A \C axis structure of Knife Blade Grinding Machine::

The A axis rotation Angle ranges from ±90 °.

The C axis rotation Angle ranges 360 °.

Servo motor drives reducer to achieve shaft rotation .

The reducer with high precision and high rigidity can

make.

shaft A and C bear force and avoid the negative