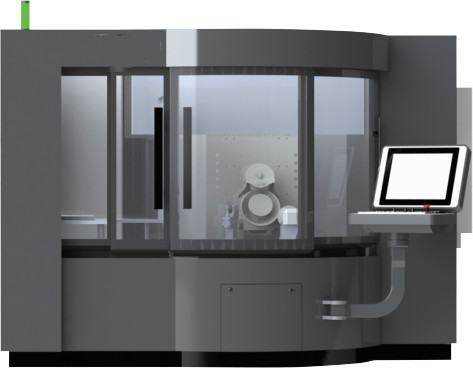

>Multi-function

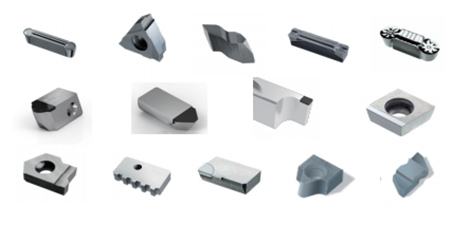

HP250-T 5-axis CNC insert grinding machine can grind all kinds of groove inserts, molded inserts and non-standard inserts by changing the clamping system, and it can also be used for grinding standard indexable inserts; a single clamping can meet the edge, groove and chamfering grinding of inserts at the same time, and the processed materials include cemented carbide, metal ceramics, ceramics, CBN, and PCD.

>High quality

The five feed axes involved in grinding all adopt closed-loop control, which can complete the grinding process with high precision. The standard 3D-probe can measure multiple angles of blanks and finished products, and the system can automatically compensate according to the measured values of finished products to improve the precision of products.

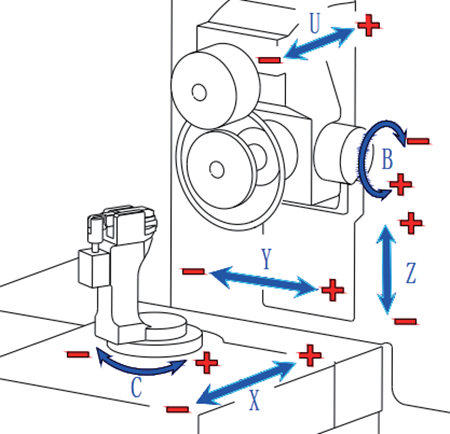

>Overview of each axis

X-axis Forward and backward movement of the table

Y-axis Left-right movement of the grinding wheel

Z-axis Up and down movement of the grinding wheel

B-axis Angle change of the grinding wheel

C axis Table rotation

U-axis In-line cleaning axis

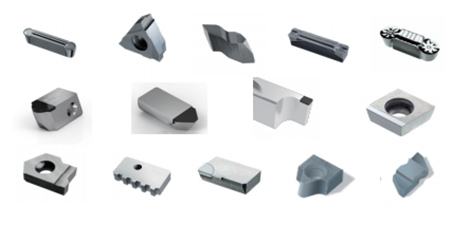

>Clamping systems

A wide range of clamping systems is available to meet different insert clamping requirements. Fully automatic indexable insert clamping systems for inserts with an internal diameter greater than 3 mm and an external diameter of up to 50 mm, and spigot mounted clamping systems for inserts with a diameter of 1 mm up to 10 mm ensure that all grinding operations can be completed in a single clamping.