This polishing machine is designed for mass production and single face grinding or polishing for small or big size workpiece.

Woekpiece include: sapphire, optical glass, aluminum alloy, stainless steel, light guide plates, ceramics, valve plates, and oil or misering diamond drill bits.

Working Principle of MSH-910LP-3Q Polishing Machine

It's a precision lapping device. The workpiece rotates counterclockwise on the disc, then is subjected to pressure through gravitational force, and it rotates relative to the grinding disc while rubbing against it, thereby achieving the grinding effect.

The polishing machine uses an oil-pressure suspended guide rail, then combined with the Diamond Dressing File/Diamond Hone, making the precisely polish to ensure the disc achieves a fine surface roughness.

Features of MSH-910LP-3Q Polishing Machine

The flatness of the grinding disc can reach ±0.002mm; The flatness of a 50mm diameter workpiece after processing can reach 1/4 wavelength.

The workpiece can be pressurized using a weight block method, and the pressure is adjustable.

It adopts PLC program control and a touch screen operation panel. The grinding disc rotation speed, timing, and grinding time can be directly input on the touch screen. Adjustable speed, operation conveniently.

The grinding disc adopts a water-cooled circulation system, and the temperature can be controlled at a low temperature with an error of ±1℃, which solves the problem of workpiece deformation caused by heat generation during grinding.The gravity-operated cylinder has a protective locking function (i.e., it can maintain its original state in the event of power failure or air failure).

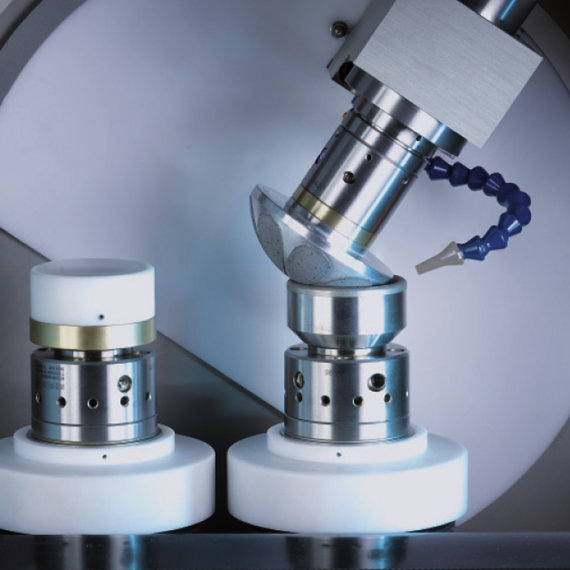

It's set up with three workstations (including three sets of pressure and self-locking systems), which can simultaneously perform polishing and grinding of 3 sets workpiece.

Grinding fluid (or coolant) circulation and filling system.