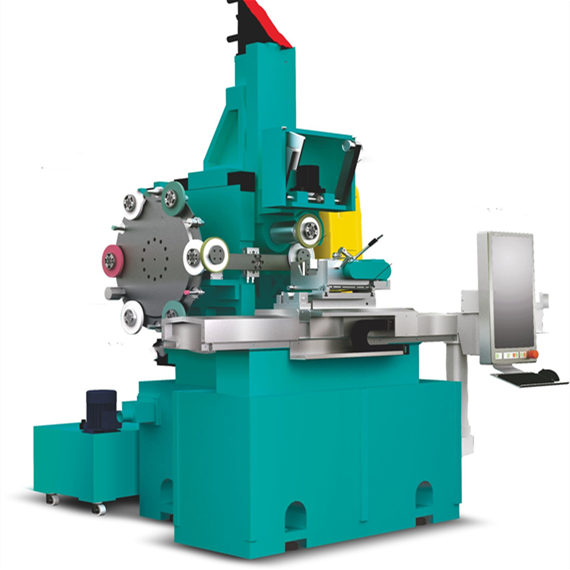

What is a surface grinding machine?

The Surface Grinder is mainly used in the finishing process. It is a very precise tool which uses a stationary, abrasive, rotating wheel to shave or finish a metallic surface which is held in place by a vise. This vise, which is part of a table, or carriage is moved back and forth under the abrasive wheel. A surface grinding machine employs a rotating abrasive wheel to precisely remove material from the workpiece's surface, creating a flat and finely finished surface. The grinding wheel is mounted on a spindle, while the workpiece is held in place on a reciprocating table.

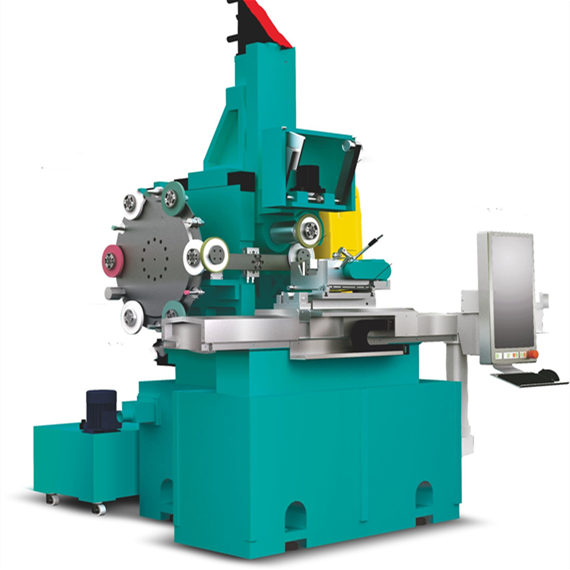

How to use surface grinding machine?

CNC surface grinding machine is a kind of processing equipment, which is used to process all kinds of materials for surface precision machining. This equipment has the characteristics of high precision, high efficiency and intelligent operation, and has been widely used in the manufacturing industry. However, due to the complexity of the equipment's structure and operating requirements, incorrect operation may lead to serious safety issues and equipment failure. Therefore, the correct operation and use methods are very important.

1. Equipment commissioning and maintenance of surface grinding machine

Before using the CNC surface grinder, the debugging and maintenance of the equipment must be carried out. According to the provisions of the equipment operation manual, carry out a comprehensive inspection and debugging of the equipment, including checking the balance of the bed, whether the electric horn and solenoid valve are working properly, whether the cycloid reducer and transmission system are functioning normally, and whether the tool clamping is firm.

2. CNC Programming of surface grinding machine

CNC programming is one of the important steps in using a CNC surface grinder. Before programming, first make sure that the power supply and compressed air supply of the equipment is fully connected, while confirming the accuracy of the position of the equipment table. Programming also need to understand the process requirements of the processed device, before starting to write the program, should be familiar with the operating essentials of the CNC system, to ensure that the program's pre-processing process is completed successfully.

3. Data input and debugging of surface grinding machine

After the program is written and checked for errors, the need for data input and debugging. Before debugging, it is necessary to complete the data input of each system, including the working area, machining depth, cutting rate, machining feed speed and other parameters. Then manual debugging of the equipment, adjust the processing position, speed and method of the equipment to ensure that the equipment can be properly executed in automatic processing.

4. Equipment safety operation of surface grinding machine

In the operation of CNC surface grinding machine, in order to ensure the safety of the equipment, be sure to comply with the following rules:

a. The operator must wear safety protection equipment that meets the requirements, such as helmets, gloves, goggles, masks and so on.

b. Equipment operation before the need to accurately determine the state of the equipment, not in a state of confusion to open the equipment.

c. During the processing of the equipment, the operator should operate the grinder in strict accordance with the program appointments and requirements, such as the discovery of equipment anomalies, the equipment must be stopped in a timely manner.

d. In order to prevent the processing environment from affecting the equipment, the processing environment should be kept clean and tidy.

e. The operator should strictly abide by the production operation specification and at the same time, carry out daily maintenance of the equipment to keep the machine and equipment in the best condition.