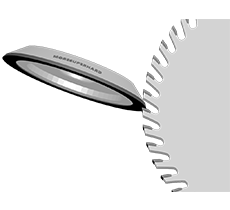

Depending on the tooth pitch, differently shaped grinding wheels are needed to grind the tooth face. The greater the number of teeth around the circumference, the narrower the space between them and the thinner the grinding wheel has to be. Even the narrowest tooth gaps can be machined with our grinding wheels. For reasons of stability, conventional tooth gaps are mainly ground using 4A2, 12V2 or 12V9 grinding wheels.

.jpg) Grinding Parameter:

Grinding Parameter:

Grinding tool: Tiger or Tiger II

Machine: Vollmer

Coolant: Oil

Work-piece: Carbide-tipped circular saw

Grinding parameters

Feed: vf = 3…10 mm/s

Infeed: ae = 0.05...0.2 mm

Cutting speed: vf = 45 m/s

Specific material removal rate: Q‘w = 0.15…2 mm³/mm · s

.jpg)

.jpg)

.jpg)