Founded in 2014, Moresuperhard is a high-tech enterprise integrating research, development, production and sales of precision superhard grinding tools. Currently, our company is in the stage of rapid development, and the existing products are widely used in the aerospace, high-end cutting tools, 3C, PCB, automotive, compressor, double-end, semiconductor and optoelectronic, woodworking and mold industries. Among them, the double end grinding discs are widely used for high efficiency flat surface machining, which can simultaneously process and complete two high-precision parallel end surfaces of the workpiece in one grinding process.

At present, in order to meet the needs of modern industry,

double endface grinding machine and

double endface grinder are developing in the direction of precision and full automation, and the double endface CNC grinding process is also widely used in industrialized production. It reduces the processing time and procedure and improves the production efficiency by grinding two parallel end faces at the same time, which is both efficient and environmentally friendly compared with the traditional grinding process.

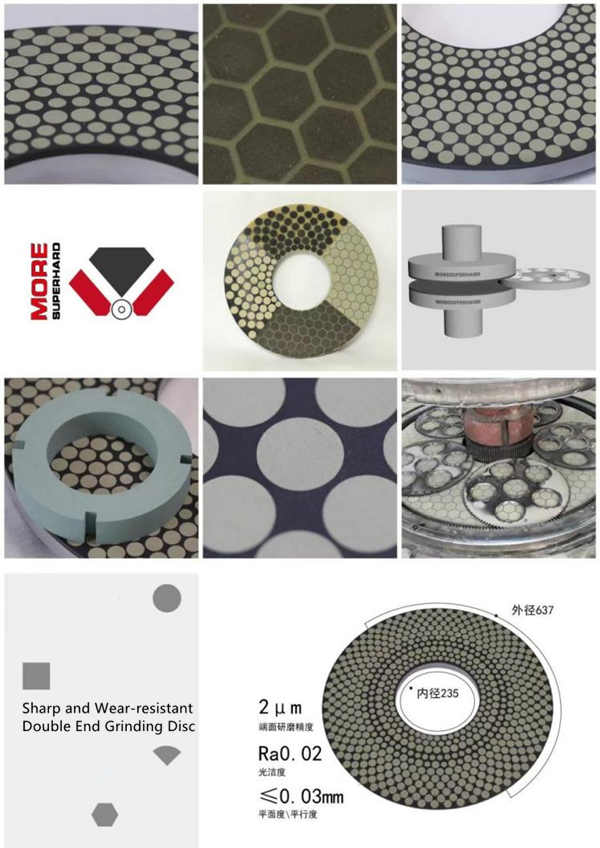

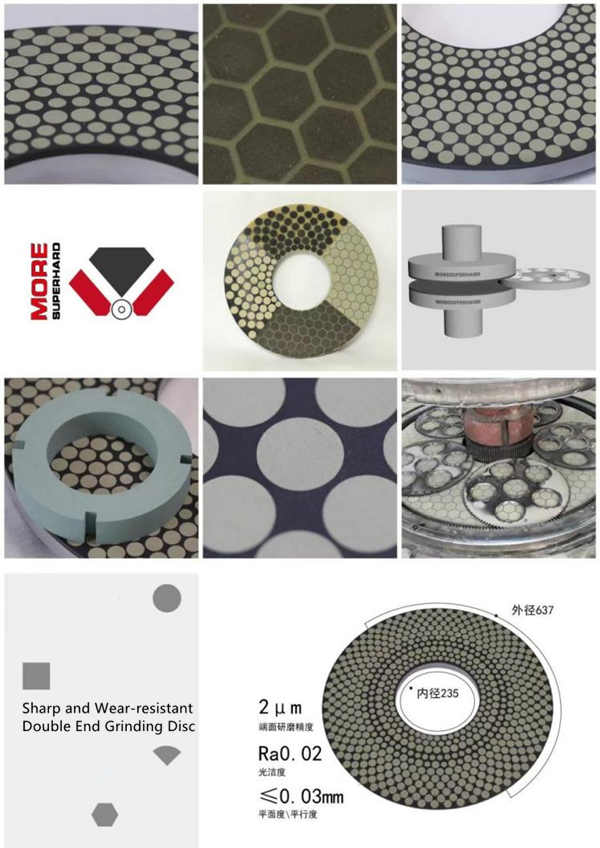

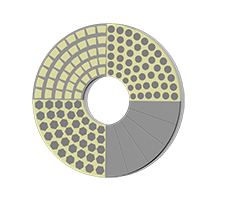

Precision grinding, sharp and wear-resistant, vitrified double face grinding discs

Precision grinding, sharp and wear-resistant, vitrified double face grinding discs

Suitable for processing hard and brittle workpieces

Features of Vitrified Double Face Grinding Discs

1. Good sharpness

Grinding discs have a certain degree of self-sharpness, friction discs, for example, the average processing beat from the original 5min / disk down to 3min / disk.

2. Good versatility

It can be applied to grinding a variety of materials, such as friction discs, carbide, nitriding steel, bearing steel, aluminum oxide, etc..

3. High precision

The shape of the grinding wheel is well maintained when grinding, and the precision of the ground workpiece is high, and the flatness can reach 0.001mm.

4. Long dressing interval

The self-sharpness of the grinding wheel is good, the dressing interval is long, the dressing interval is more than 50% higher than the general formula, and the grinding of hard-to-grind friction disk workpiece is increased from 5 disks/revision to more than 15 disks/revision.

5. Good wear resistance

The wear resistance of the new R&D product is greatly improved, and the average loss per disk is reduced by more than 30%.

Vitrified diamond double end grinding wheel in the metal, ceramics and other special materials grinding process, has more and more obvious advantages, is considered to be efficient, high precision, low grinding cost, environmental protection of the high-performance grinding wheel, with more and more extensive applications, is the recent world grinding tools competing for the study of the hot spot.

Double end grinding disk has a wide range of applications in industrial production, suitable for a variety of parallel endface workpiece double endface grinding, covered by applications such as: semiconductor industry: Si, Sic, GaAs, GaN, InP, MEMS, ceramic substrates, and so on. Hydraulic industry: piston pumps, oil distribution plates, ball valves, piston rings, compressor valve plates, return disks, seals, oil nozzles and so on.

Automotive parts industry: gaskets, stators, rotors, oil pump impellers, WT pressure plates, brake discs, automotive steering valves, gear pumps, automotive rotary pumps, precision bearings, etc. Optical crystal industry: optical crystal, optical lens, glass substrate, ITO glass, sapphire glass, etc. Communication industry: cell phone ceramic fingerprint identification chip, cell phone camera bracket, card pin, card slot, 5G filter, etc. Cutting tool industry: carbide cutting tools, CBN cutting tools, ceramic cutting tools, metal-ceramic cutting tools, etc.

As a company deeply engaged in the field of grinding, Moresuperhard can meet the strict tolerance requirements in the micron range according to the grinding needs of customers in various fields and no matter what kind of material the workpiece is made of. Henan Moresuperhard has specially designed formulas for precision grinding of all kinds of small, medium and large workpieces that also require high parallel accuracy, which fits the needs of users.

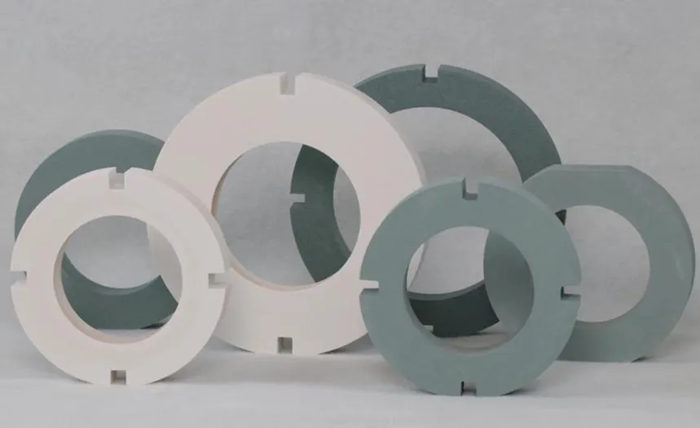

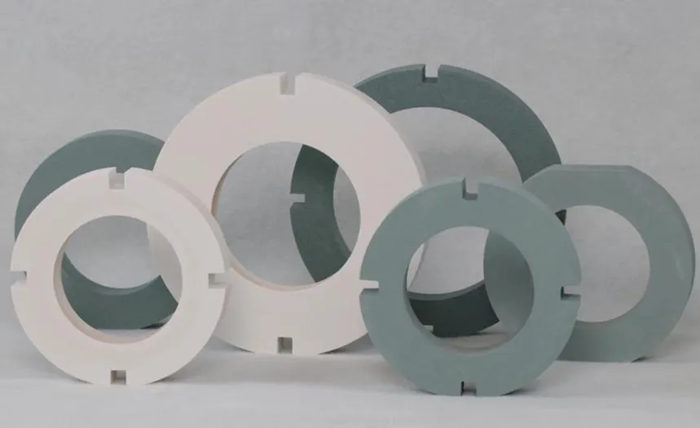

At the same time, Moresuperhard is equipped with dressing rings, which are used in the grinding process of diamond/CBN grinding discs for leveling the flatness after the deformation of the face shape and in the use of the grinding discs for dulling the open edge and sharpening the edge, so as to solve the grinding problems for the customers while taking into account the dressing problems.

.jpg)