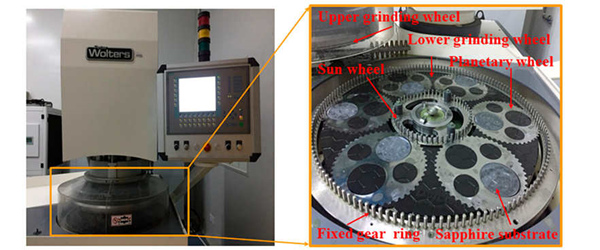

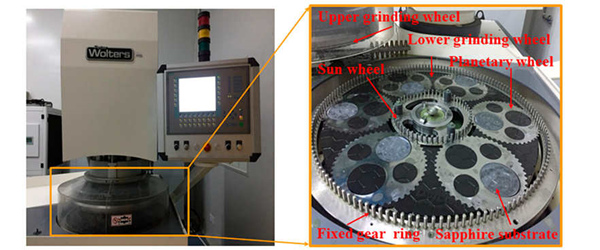

Double-Disc Grinding is a highly efficient grinding method that reduces premachining costs up to 50% and provides dimensional tolerances, parallelism, and flatness to ±.0002″. Double-Disc Grinding uses two opposing abrasive wheels to simultaneously grind two sides of the material. In one operation, equal amounts of material are removed from both sides. Grinding two sides of a part at the same time provides greater control of dimensional tolerances, flatness, and parallelism.

Stress Reduction

Stress Reduction

Internal stress relief is another Double-Disc Grinding benefit. Simultaneously removing equal amounts of stock from two sides of a blank reduces residual stress. Less residual stress improves part stability during secondary operations and final machining.

Supports Stacking & Spot Facing

Double-Disc Grinding provides optimum part-to-part parallelism and flatness consistency, making it ideal for material to be stacked or spot-faced in machining operations. Parallelism and flatness tolerances are held consistently even on large, hard-to-machine parts.

High Volume Grinding

Automated Double-Disc Grinding furnishes cost effective thickness sizing for small parts such as fine blanked stamped, die cast, and sintered metal parts. Through automation, the production costs of large quantity runs are significantly reduced.

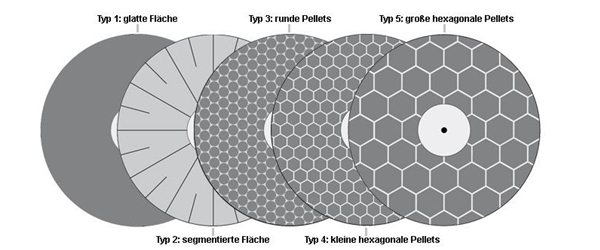

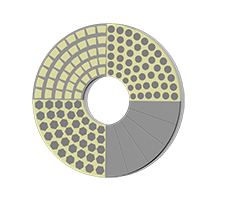

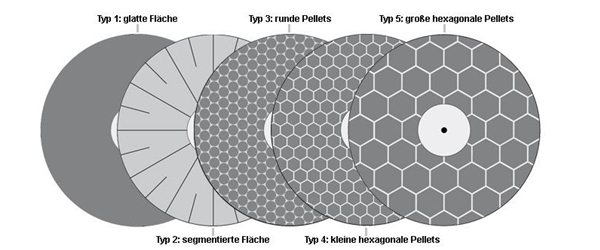

More SuperHard company offers a full line of

diamond and CBN grinding wheels and dressing stones for fine grinding machines and single and double side lapping systems. Our vitrified diamond and CBN grinding discs have high grinding efficiency, high wear resistance and abrasive consumption, good surface quality and flatness of the workpiece.

1.Grinding disc made of CBN abrasive is suitable for single/double end grinding of flat workpieces such as cylinder block, valve plate, sliding plate, connecting rod, oil distribution plate and blade, automotive pump rotor and stator , etc.

2.Grinding disc made of diamond abrasive is suitable for single/double-sided grinding of ceramic, monocrystalline silicon, magnetic material, plastic, aluminum and other workpieces.