First of all, let's understand the related content of centerless grinding wheels. There are some quesitons and answers below which may help you to understand.

1. Which centerless grinding machines will customers choose?

Centerless Grinder Machine:

Koyo, Crystec, Dedtru, Landies, Okuma, Paragon, Royal Master, Unison, WMV and so on.

Centerless grinding machine in the operation will sometimes have

the problem of inaccuracy, so how to adjust the inaccurate feed of the centerless grinding wheel become customer's concern.

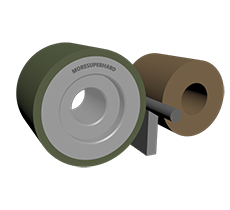

Moresuperhard has the 1A1 , 6A1, 9A1 resin/metal bonded grinding wheels

for

centerless grinding machines. Customers can use our ceterless grinding wheels to gind

carbide, ceramic, magnetic materials, stainless steel bar, PCD & PCBN compositives.

.jpg)

2.

How to adjust the inaccurate feed of centerless grinding wheels?

The inaccuracy of feed in the operation of centerless grinding machine is due to the fact that most of the traditional ordinary centerless grinding machine in China uses ordinary screw as feed drive. Because there is a gap in the lead screw, it will lead to direct feeding will certainly be inconsistent with the actual feeding value, and high precision centerless grinding machine because of the use of ball screw, the error will be relatively small.

(1).jpg)

The usual operation method is that we return three rounds when feeding, and then enter three rounds to eliminate the error generated by the gap. If the feeding is not correct, we need to carry out other operations.

a. See if the screw brake handwheel is locked. If it can't be locked, the two pins that brake the handwheel tap with the screw rod inside may be dropped, and it is necessary to check and reassemble. If the slide plate is not allowed to enter the knife, it is necessary to check whether the left or right side of the tool holder meets the falling workpiece. This kind of problem sometimes occurs and needs to be checked.

b. For the centerless grinder model, because it is from the lower right corner of the feed, it should check whether the fixed screw of the feed hand wheel fine tuning and the check screw on the feed screw is loose or too large clearance, and rotate the feed hand wheel several times to feel whether the clearance of the hand wheel is too large, or whether the feed hand wheel is too tight when it rotates.

c. The deviation or loosening of the position of the feeding bushing will lead to a large gap between the friction helical gear and the adjusting screw. Or tight nut caused by rotation is not flexible, in general, nut loosening will also cause the phenomenon of no feeding.

d. Hand wheel fine tuning and screw differential disc inside the transmission screw has fixed screws, but also to ensure that there is no loosening, fine tuning screw and screw above the pilling bearing also to ensure that there is no wear or clearance is too large.

Last but not the least, for slight wear, it can be properly tightened, wear serious parts need to be replaced in time, try to use good quality parts, can improve the accuracy of grinding machine feeding, reduce the maintenance rate of the machine.

Moresuperhard is always committed to providing

better diamond grinding wheels for our customers and hope to provide them with a better experience of using them. If you have any questions when using our products, please contact us in time, and we believe our expertise can solve the problem for you well.

---EDITOR: Sarah Shi;Jackie Wang

---POST: Jackie Wang

.jpg)

(1).jpg)