In recent years, some custormers consult Moresuperhard's vitrified diamond grinding wheels and peel grinding wheels used on notebook computer Magnesium Alloy structural parts grinding.

Due to the increasing demand for mobile portability, thinning has become an important trend in the design of notebook computers. In order to achieve a thin and light design, in addition to the thickness control of the internal components of the notebook computer, the volume and integration of the components continue to improve, the selection of lightweight and high-strength shell materials such as magnesium alloy and carbon fiber is also very necessary.

Among them, magnesium alloy, as the lightest engineering metal material, is known as "green engineering material in the 21st century", with a density of 1.74-1.85g/cm3, 36% lighter than aluminum alloy, 73% lighter than zinc alloy, only steel Therefore, the specific strength and specific stiffness are high, and at the same time, the damping, electromagnetic shielding, vibration damping, machinability, polishing and surface treatment performance are excellent.

What is the magnesium alloy and what are the characteristics of it?

Magnesium alloys are alloys based on magnesium and other elements.

Low density, good specific performance, good shock absorption performance, good electrical and thermal conductivity, good process performance, poor corrosion resistance, easy oxidation and combustion, and poor heat resistance.

Its processing, corrosion and mechanical properties have many characteristics: fast heat dissipation, light weight, good rigidity, certain corrosion resistance and dimensional stability, impact resistance, wear resistance, good attenuation performance and easy recycling; In addition, it has the characteristics of high thermal conductivity and conductivity, non-magnetic, good shielding and non-toxic.

Scope of application: magnesium alloy is widely used in portable devices and automotive industry to achieve the purpose of lightweight.

At present, under the requirements of light weight, the weight of the light and thin notebook computer is basically below 1000g, and the main thickness of the structural parts is 0.5~0.6mm. The traditional die-casting process can no longer meet the requirements. Therefore, the processing of magnesium alloy thin-walled parts of notebook computers mainly adopts Semi-solid injection molding, and a small amount of stamping molding, the main process is micro-arc oxidation and painting.

.jpg)

Since there are still many problems with the appearance of magnesium alloy die castings and the timeliness of MAO treatment, magnesium alloy structural parts processing manufacturers basically have a full-process supply chain from forming to surface treatment. Due to the small size and high precision of the components of the notebook, the machining often involves a precision grinding process.

.jpg)

Grinding Solutions:

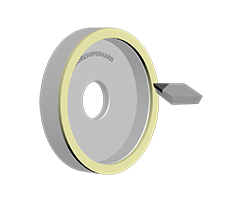

1. 6A2 Vitrified diamond grinding wheel

Grain size selection of 6A2 vitrified diamond grinding wheel

► W40(500# D35) W28(D20)

Rough Grinding.

► W20 (800# -1000#, D20)

Universal Grinding.

► W10 (1500# D15A) W7 (2000# D15B)

Finish Grinding.

► W5 (3000# D7) W3.5 (4000# D3)

Super Finish Grinding.

2.

Electroplated plated Cylindrical Peel Grinding Wheel

Application: external cylindrical grinding of milling cutters, drills and wire tapping, grooves, flats, threads and chamfers, etc

Peel grinding operations of a variety of diameters, grooves, thrust faces and forms using one set-up. It is suitable for external cylindrical grinding of milling cutters, drills and wire tapping, grooves, flats, threads and chamfers, etc

Features of Pell Grinding

— High-precision, high-efficiency

— Center-going, step-difference forming external cylindrical grinding

— The punches and needles are rough and finely ground at one time, and the finish is high

— With less frequent dressing in the case of vitrified CBN wheels or without dressing in the case of plated CBN wheels

With a global development strategy and comprehensive multilingual business departments, Moresuperhard keeps an eye on the latest developments in the global grinding industry and is committed to providing high-quality and efficient grinding products and services to our customers worldwide! We also accept customized orders to suit your needs.

If you have any questions about

the grinding solutions of Computer Magnesium Alloy Structural Parts, please feel free to contact us! You can leave us your questions below, and we will contact you as soon as possible!

---EDITOR: Jim Jiao,Jackie Wang

---POST: Jackie Wang

.jpg)

.jpg)