High Boron Glass Tube Inner Wall Polishing Customer Background:

The customer is a manufacturer of high boron glass tubes used in scientific and industrial applications. They have their own honing machine and require a diamond honing stone to achieve a surface finish of R0.1 on the inner walls of the glass tubes. The high boron content makes the glass tube extremely hard and difficult to polish using conventional methods.

High Boron Glass Tube Inner Wall Polishing Solution:

To meet the customer's requirements, a suitable solution is to utilize Diamond & CBN Honing Stones for the polishing process. These honing stones are specifically designed for honing hard materials such as glass, ceramics, and hardened steel.

Steps to Use Diamond Honing Stone for High Boron Glass Tube Inner Wall Polishing:

-

Stone Selection when Tube Inner Wall Polishing

Select a diamond honing stone with the appropriate grit size and bond type based on the specific requirements of the glass tube material and desired surface finish. Consult the stone manufacturer’s guidelines or technical support for the best stone selection.

-

Preparation for Tube Inner Wall Polishing:

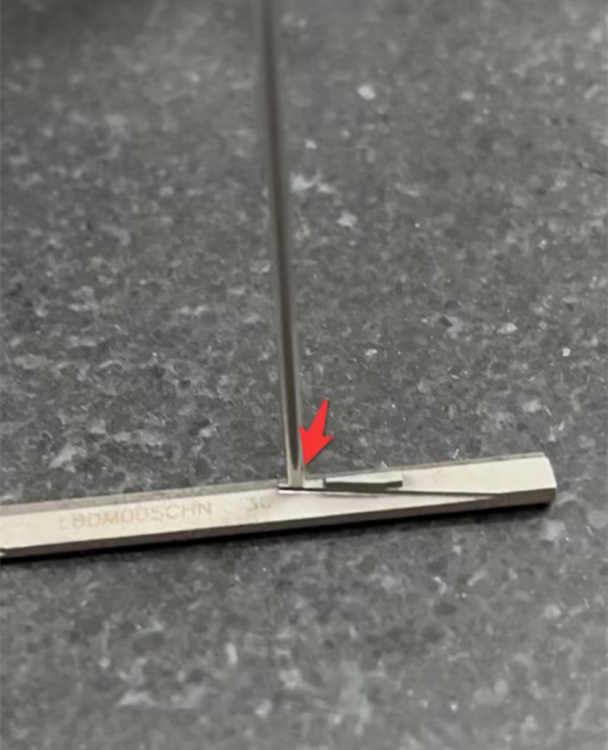

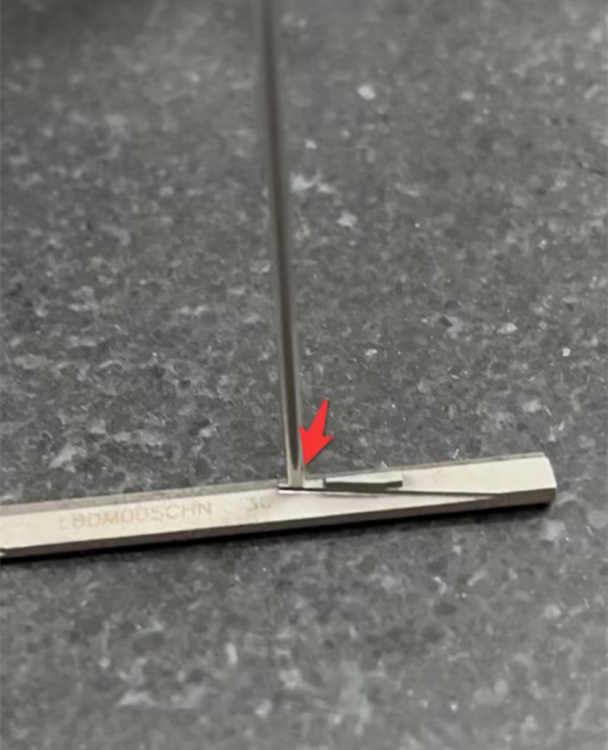

Mount the diamond honing stone securely onto the honing machine. Ensure that the stone is properly aligned with the inner wall of the glass tube to achieve consistent and uniform polishing.

-

Lubrication and Coolant:

Apply a suitable honing oil or coolant to the honing machine to lubricate the honing stone and reduce friction during the polishing process. The coolant also helps to dissipate heat generated during the honing process, ensuring effective material removal without causing damage to the glass tube.

-

Tube Inner Wall Polishing Process:

Start the honing machine and gently introduce the diamond honing stone into the inner wall of the glass tube. Maintain a controlled feed rate and pressure to achieve the desired surface finish. The honing stone’s abrasive action will gradually remove material and create a smooth and precise surface.

-

Check Surface Finish:

Periodically check the surface finish using appropriate measurement equipment such as a profilometer. Adjust the feed rate and pressure if necessary to achieve the target surface finish of R0.1.

-

Clean and Inspect after Tube Inner Wall Polishing:

Once the desired surface finish is achieved, carefully remove the glass tube from the honing machine. Thoroughly clean the inner wall to remove any residual coolant or debris. Inspect the polished surface for any defects or imperfections, ensuring it meets the required specifications.

Customer Case Summary for Tube Inner Wall Polishing:

By utilizing Diamond & CBN Honing Stones and following the above steps, the customer can effectively polish the inner walls of high boron glass tubes to achieve a surface finish of R0.1. This solution ensures precision, efficiency, and quality in the manufacturing process of the glass tubes, meeting the customer's requirements for their specific application.

---EDITOR: Julia Zhang,Jackie Wang

---POST: Jackie Wang

.jpg)