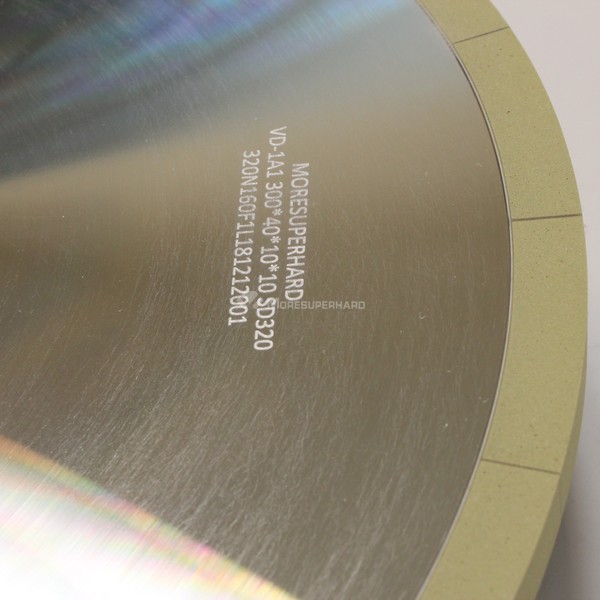

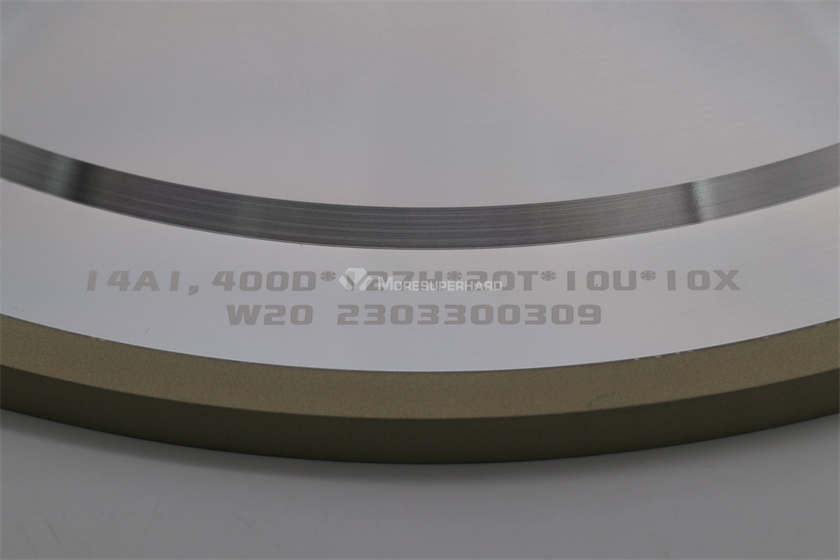

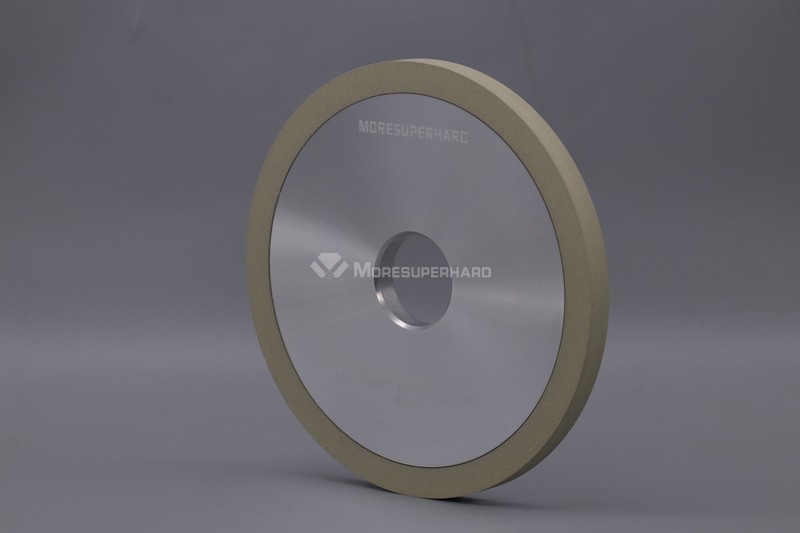

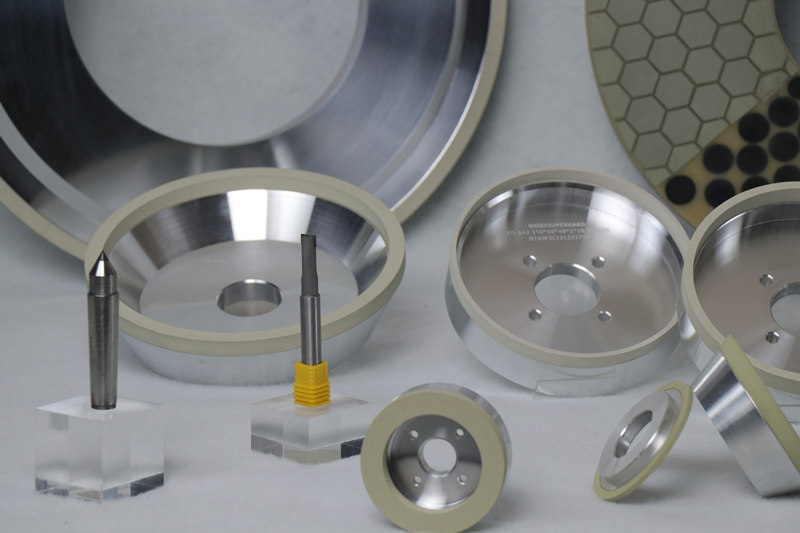

Diamond wheel – vitrified/ ceramic bond supplier

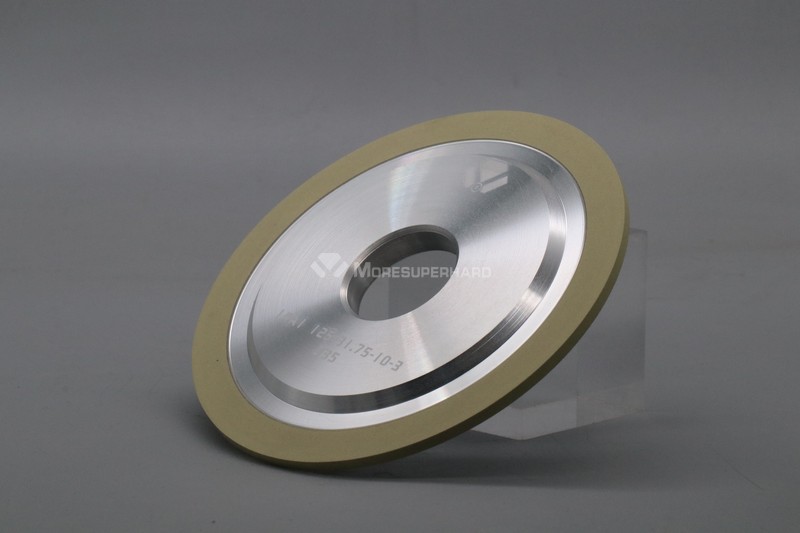

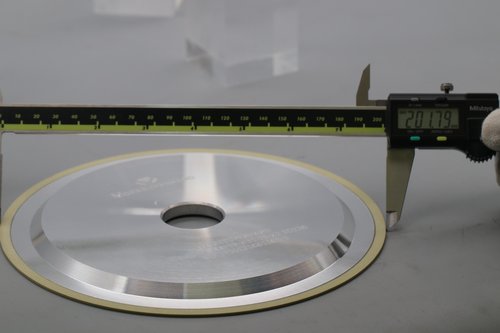

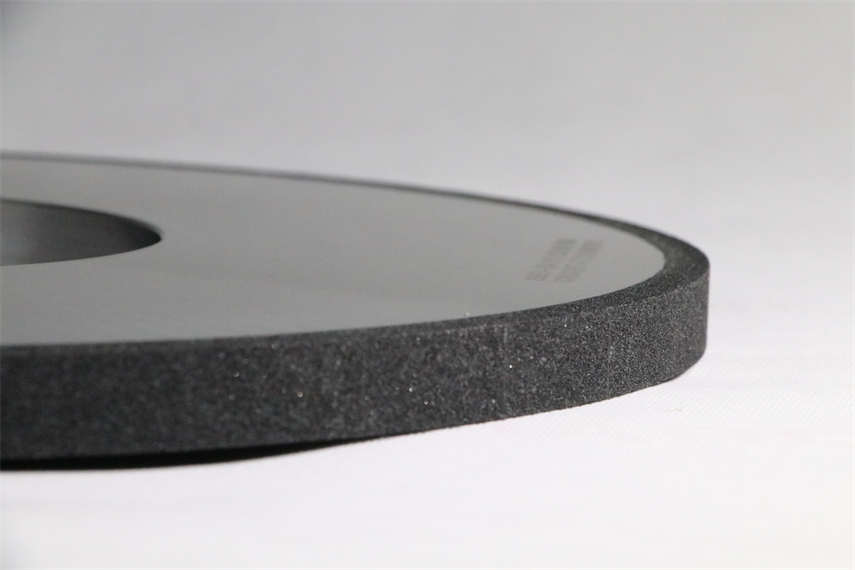

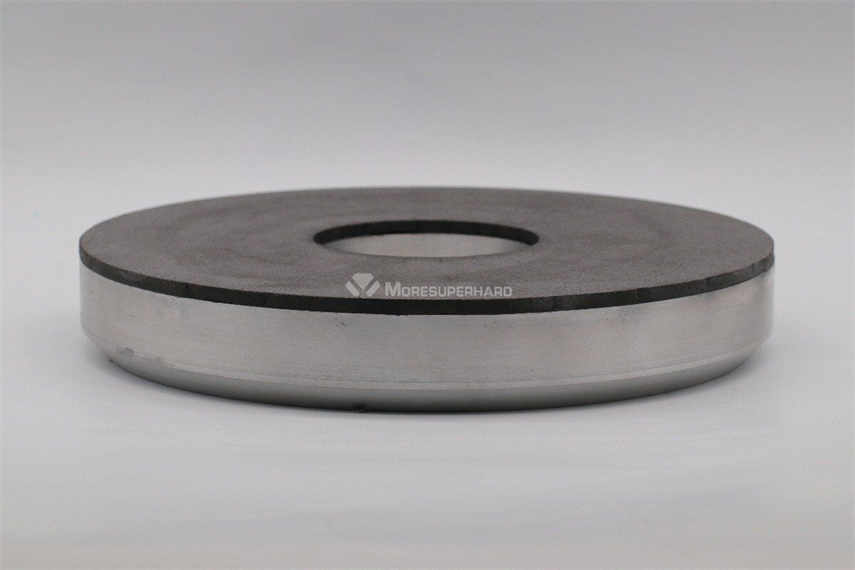

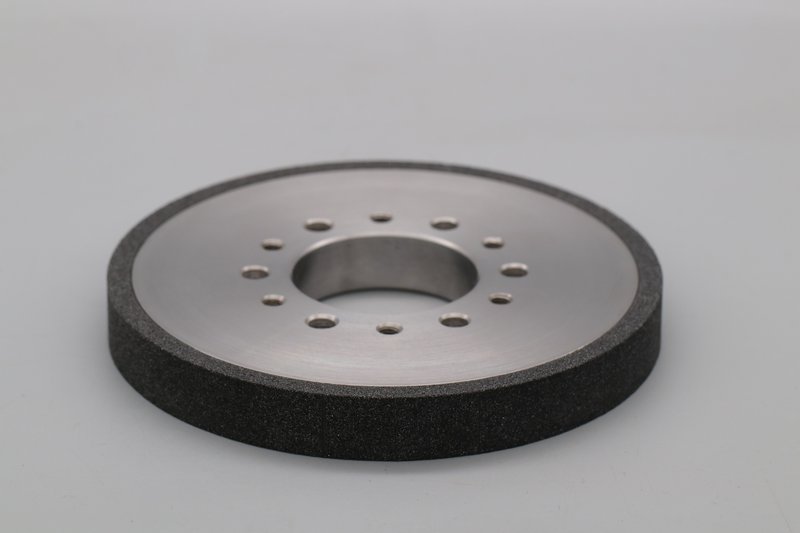

Diamond wheels- vitrified/ ceramic bond are manufactured to create higher levels of porosity.

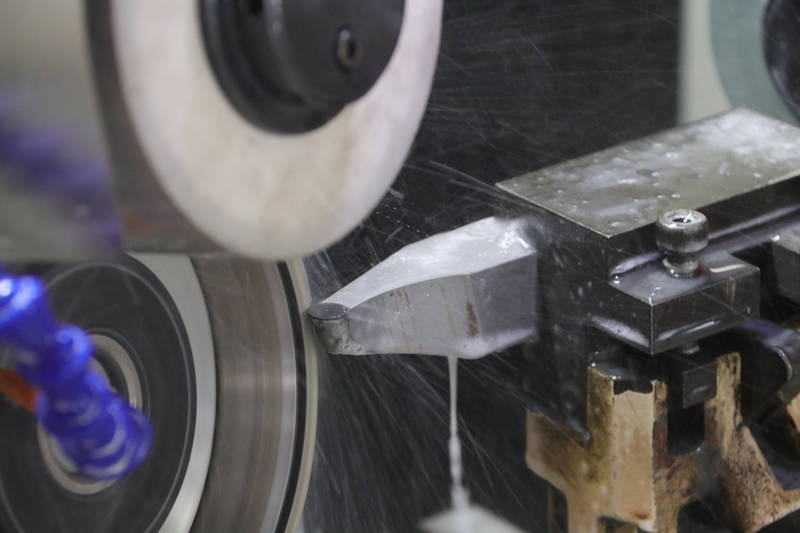

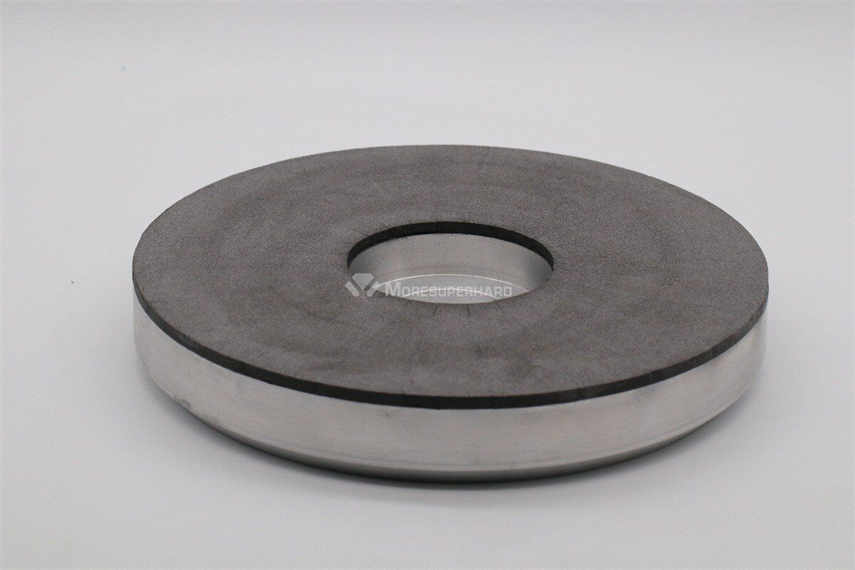

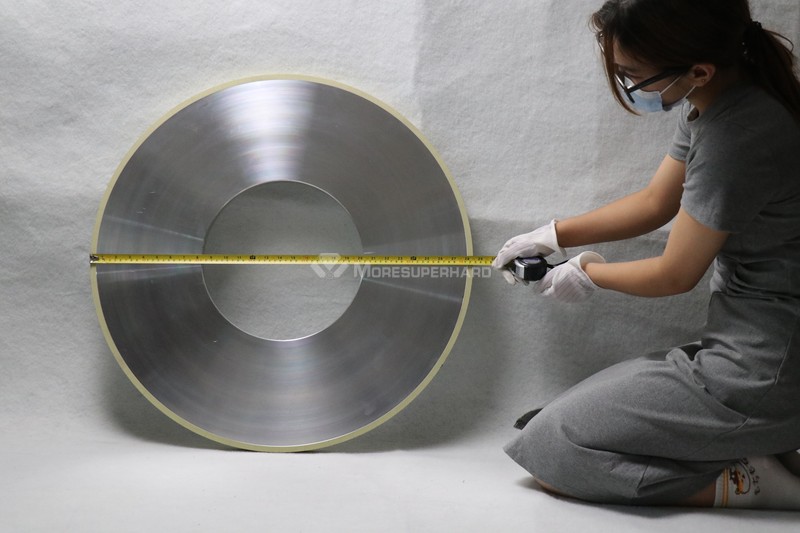

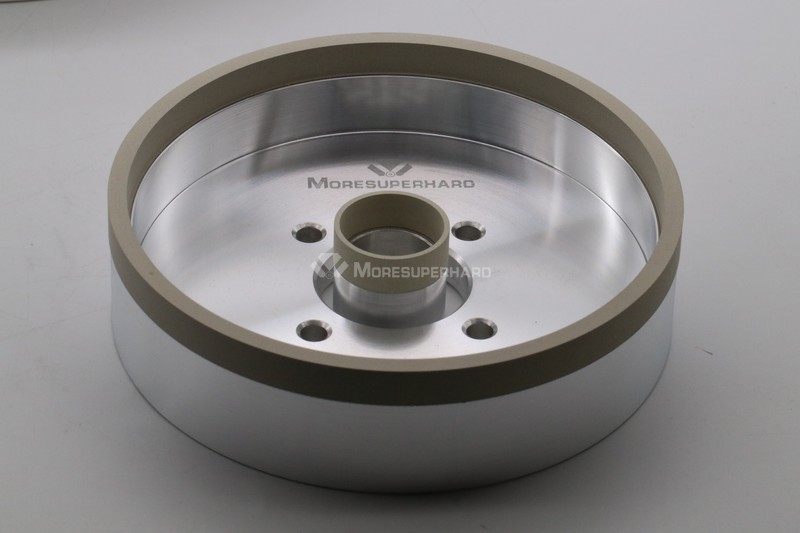

Moresuperhard Vitrified grinding wheels are an ideal choice for ball screw grinding, grinding of cast iron or steel parts such as injection nozzles, compressor blades and vanes, PCD and PCBN tool and insert grinding, plus OD grinding of automotive and aerospace industry parts.

Vitrified bond is a vitreous binding material and generally contains pores inside while other materials contain no pores. Therefore vitrified bond wheels have excellent grinding ability and are superior in forming

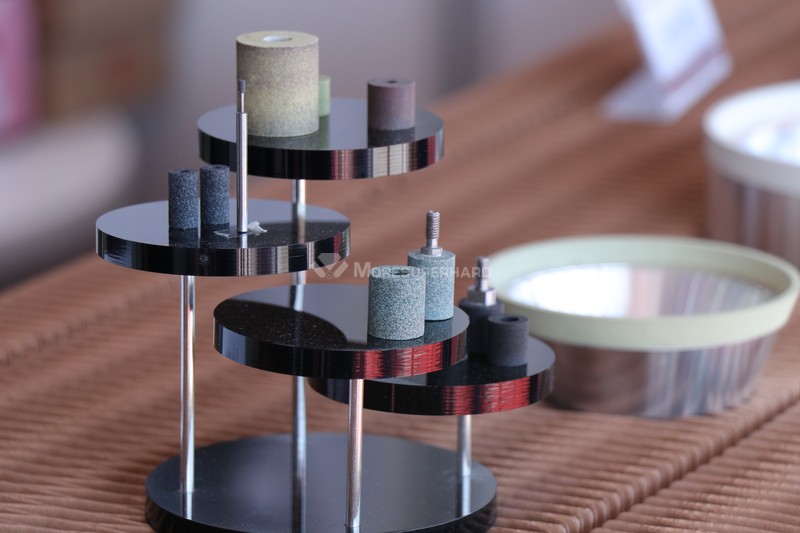

Features of Diamond wheel – vitrified/ ceramic bond

* Wheel grinding ability and wheel life depend on the combination of binding material, super abrasive mesh size, concentration, and porosity. The harder the bond, the longer wheel life is achieved. On the contrary, the softer the bond, better grinding ability is achieved because porosity becomes higher. Also higher concentration of abrasive, equates to longer wheel life.

* Automated processing is available because simultaneous operation of truing and dressing using rotary dresser on the grinding machine is possible. Cutting edges can be manipulated in such a manner that the surface finish of the part can be controlled.

* Diamond wheels have difficulty in truing and dressing with rotary dressers. Therefore surface finish depends on the mesh size of super abrasive in the diamond wheel.

Applications of Diamond Wheels

* Diamond wheel – vitrified/ ceramic bond are efficiently used for grinding difficult-to-machine materials such as PCD, PCBN, ceramics, etc.

* Diamond wheel – vitrified/ ceramic bond are generally superior in grinding ability to metal bond wheels. Because the vitrified bond has no elasticity, it is better suited for tight tolerance applications than resin bond wheels.