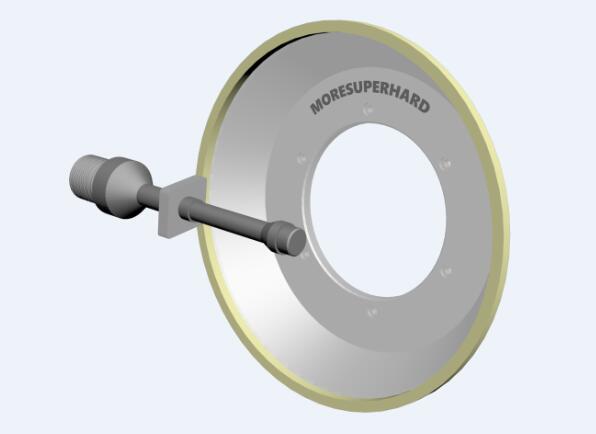

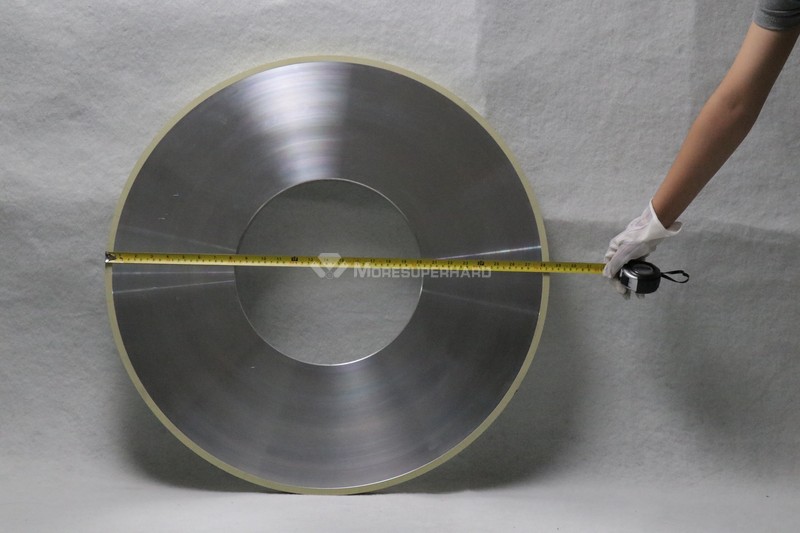

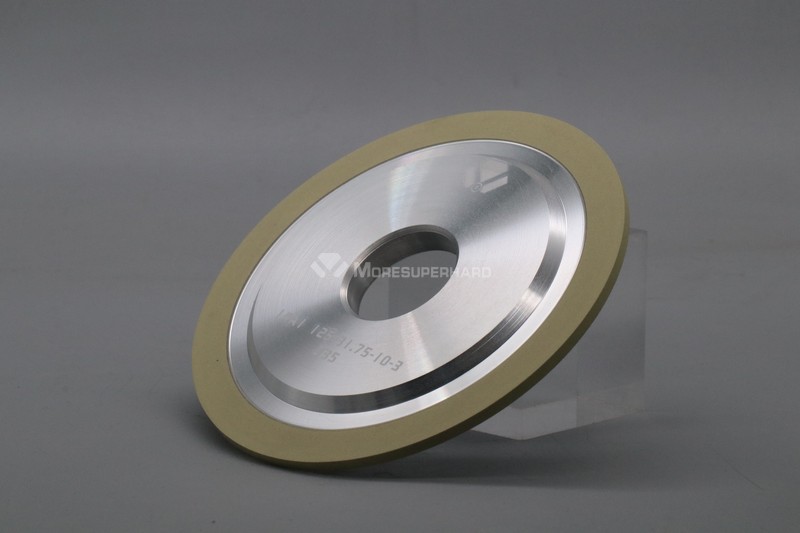

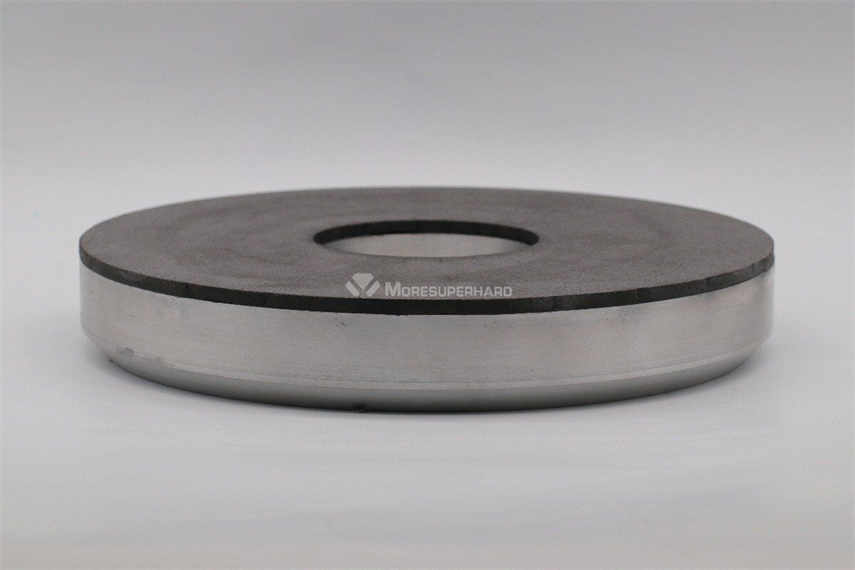

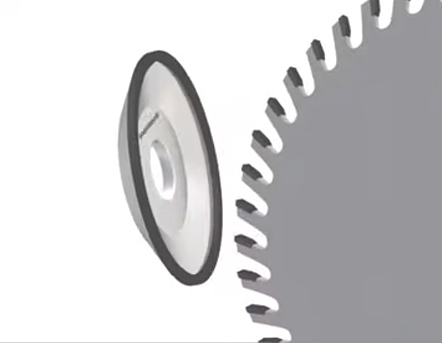

Vitrified cbn wheels for internal grinding bearing

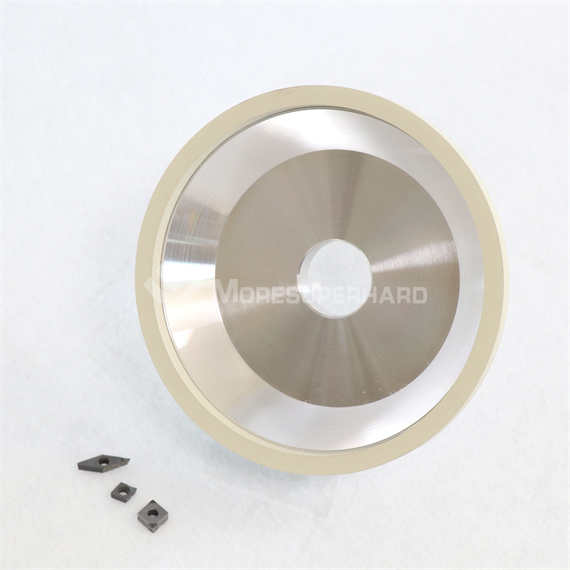

Vitrified cbn wheels are suitable for internal grinding vane pump, rotary vane compressor stator inner circle and curved surface, piston refrigeration compressor cylinder, universal joint ball path, industrial bearing inner circle or inner hole, Fuel pump nozzle etc.

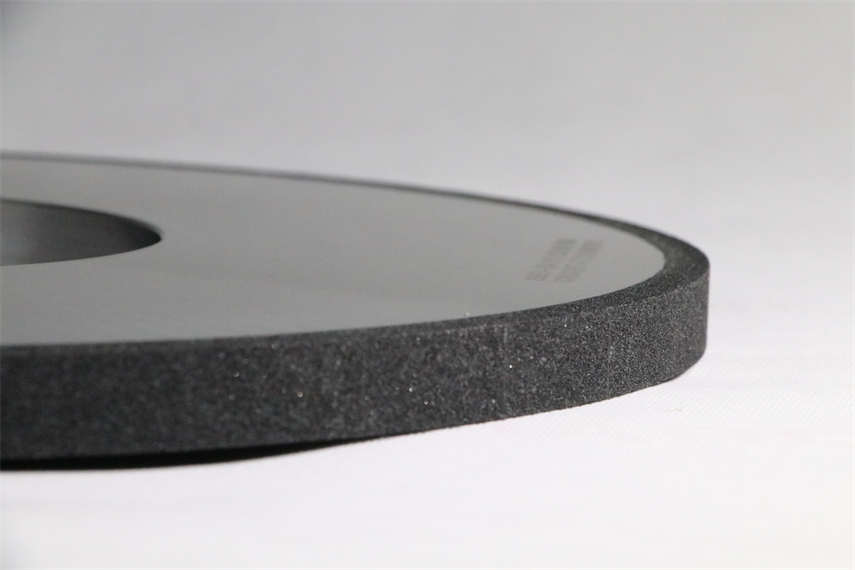

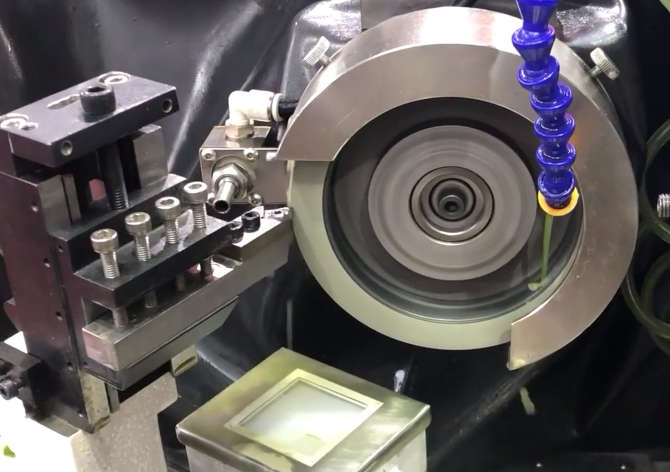

The vitrified bond cbn grinding wheel can be easily dressed with ordinary diamond tools. Due to the high hardness of cbn abrasive grains, the diamond wears quickly during dressing.

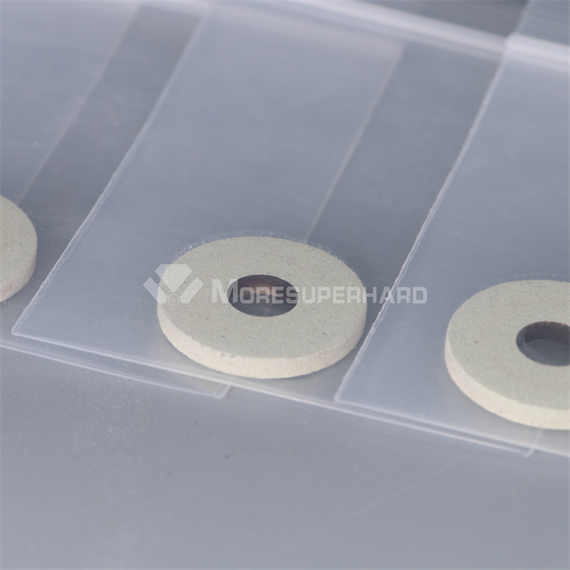

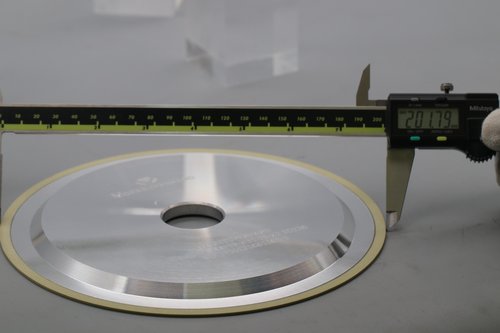

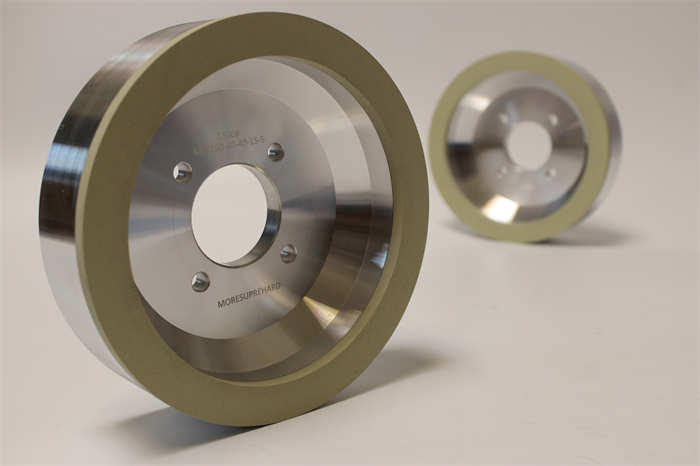

The vitrified CBN internal grinding wheel produced by our company has specifications ranging from outer diameter φ2.5 to φ75, aperture diameter φ1 to φ25, and the height can be made according to customer’s special requirements. The processing cost of a single part is 30%-50% lower than that of imported grinding wheels.

vitrified CBN internal grinding wheel is widely used in the bearing industry, sewing accessories industry, compressor industry, mold industry, pump industry and auto parts industry (hydraulic tappets, constant velocity joints, cylinders, fuel injectors, gears). Good results have been achieved in various internal grinders, coordinate grinders, and inner surface grinders.

Cubic boron nitride (CBN) grinding wheels are suitable for grinding the following materials

1 High manganese steel

2 High chromium, nickel and molybdenum alloy steel

3 Chilled cast iron (HS80~90)

4 All kinds of hardened steel (HRC55~65)

5 Various cast irons (HB200~400), etc., such as: auto parts (gears, flywheels, shafts, bearings, etc.), rolls, slurry pumps (impellers, volutes, guard plates, sheaths, etc.), molds, cylinders set

6 High-hardness, soft and tough materials such as glass and gemstones solve the cutting processing of high-hardness and difficult-to-machine materials in various industries, and can improve work efficiency, greatly save processing man-hours and electricity, and obtain huge economic benefits

7 Materials with low thermal conductivity

8 Various spraying (welding) materials: nickel-based, iron-based, etc

9 Cast iron materials: vanadium-titanium cast iron, high phosphorous cast iron, chilled cast iron, etc

10 Titanium alloys: such as TC4, etc.