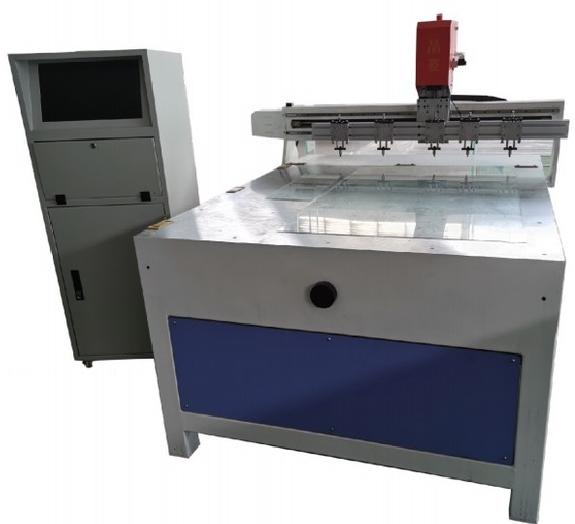

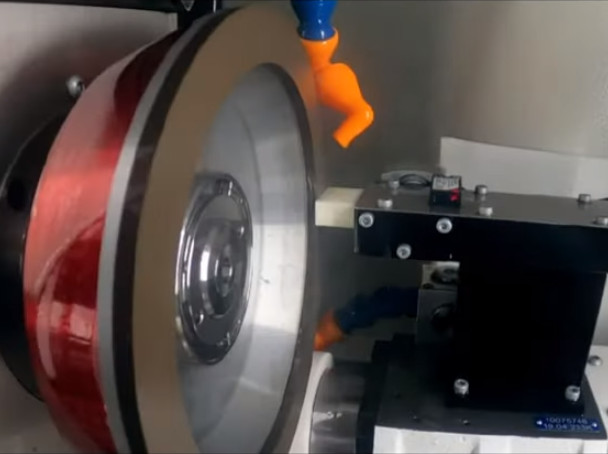

Quenched Steel Process/Grinding with Electroplated CBN Grinding Head

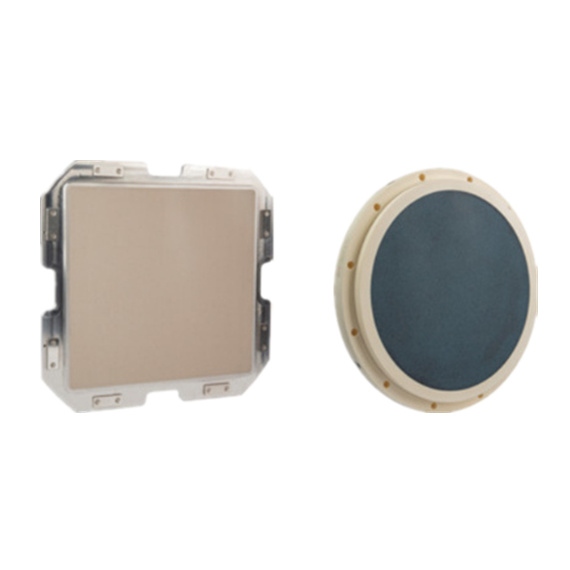

Application: sculpturing, dressing and internal grinding carbide, ceramic,glass, stones, marble,etc

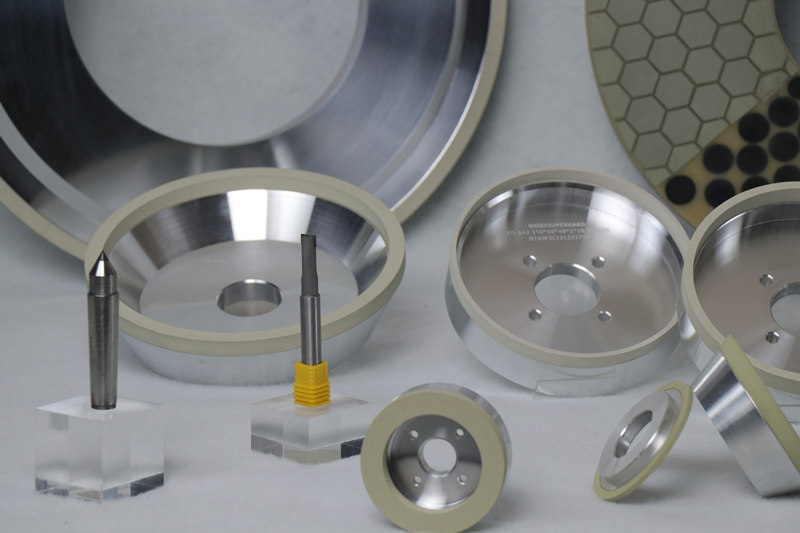

Types of internal grinding wheel:

* vitrified cbn internal grinding wheel

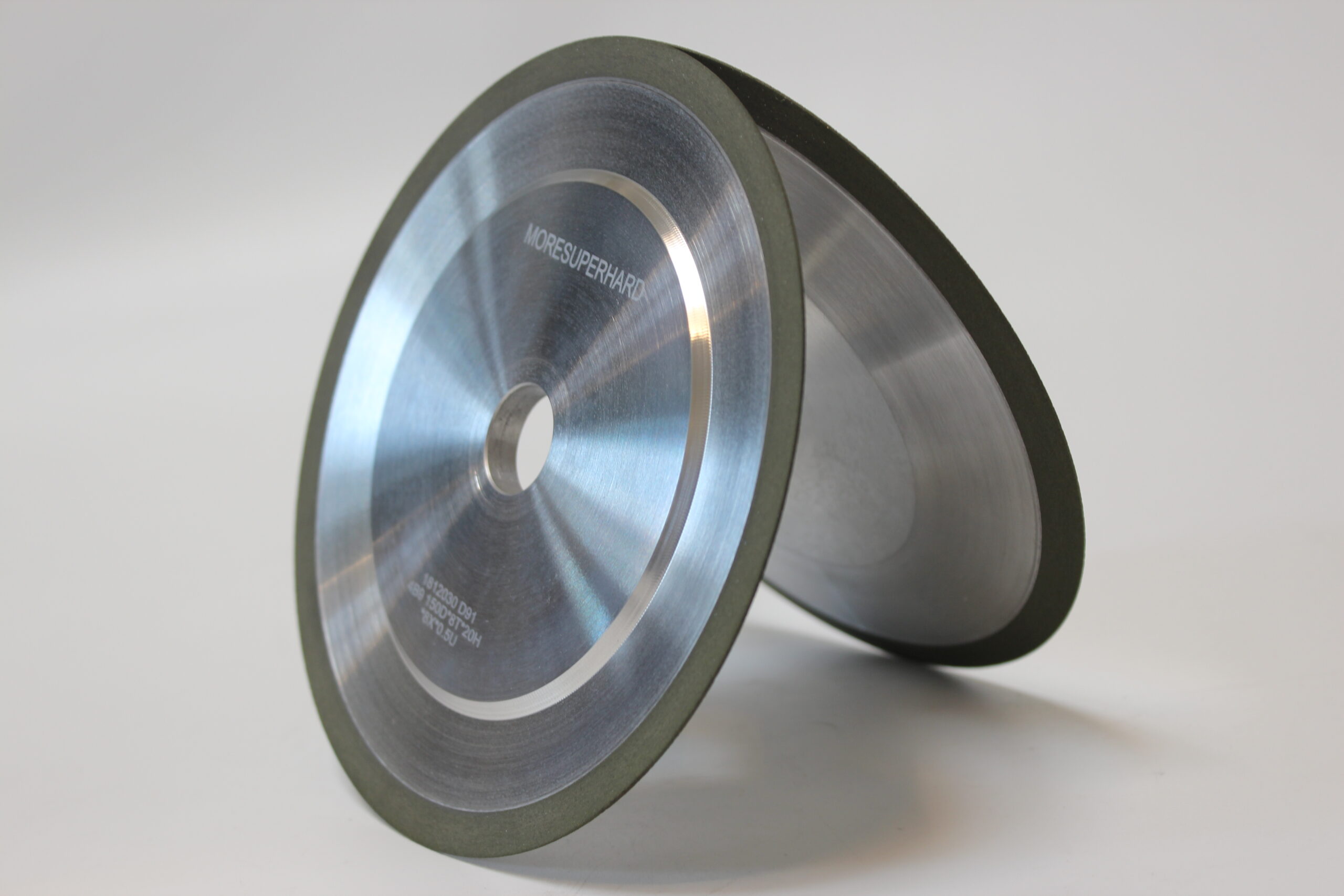

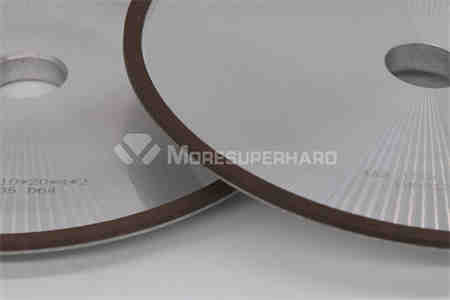

* resin diamond & cbn internal wheel

* electroplated diamond mounted points

* abrasive internal grinding wheel

Electroplated grinding wheels are an excellent option when an aggressive amount of stock removal is required.

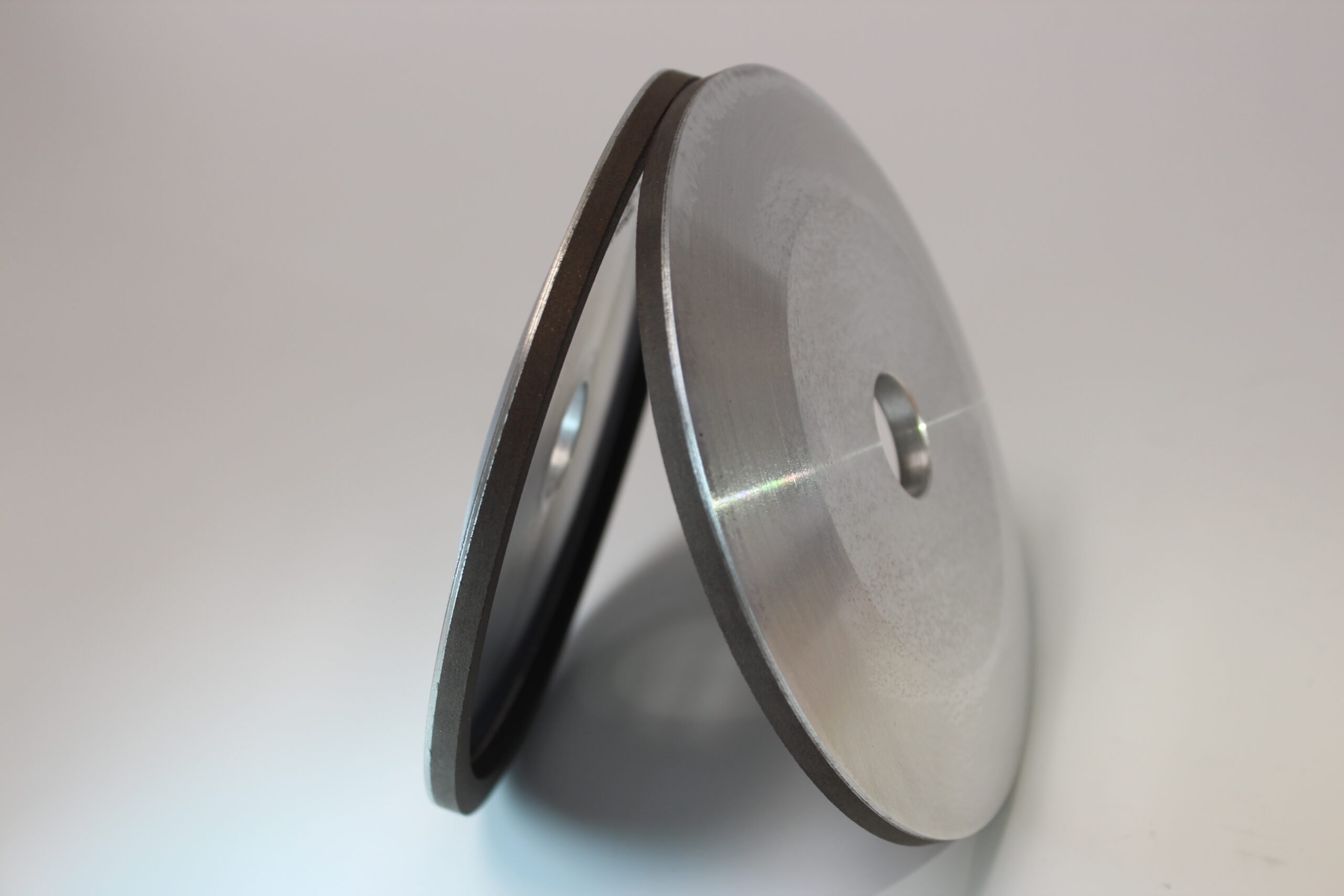

A single, uniform layer of diamond or CBN crystal is electroplated to a precision machined steel surface.

How to Produce Electroplated CBN Grinding Wheels?

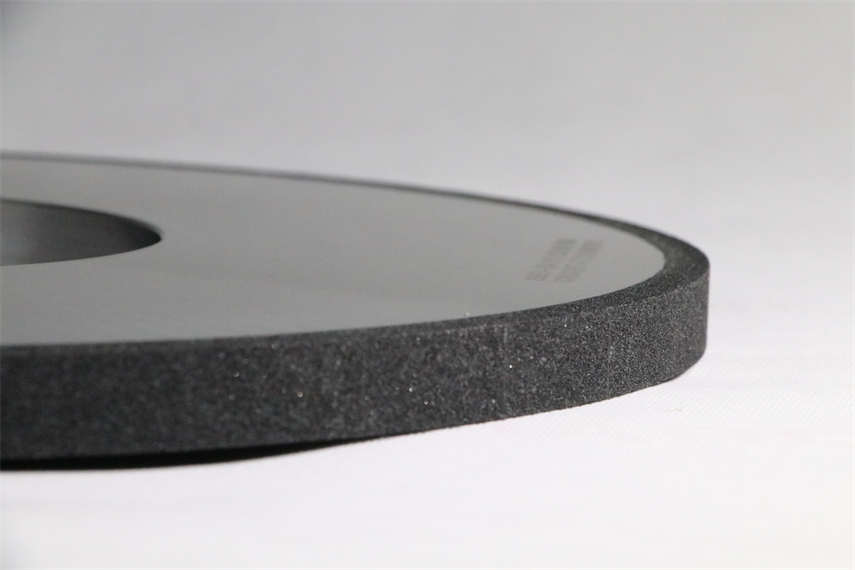

The electroplated diamond wheel is a diamond grinding wheel made by the electrochemical method. The working layer of the grinding wheel contains diamond abrasive grains, and the diamond abrasive is bonded to the substrate by a metal bonding agent. First, the thickness of the deposited metal bond is 20% of the height of the diamond abrasive grains (upper sand), and then the diamond abrasive grains are continuously bonded (thickened) with a metal bond to a thickness of about 2/3 of the height of the abrasive grains. Includes diamond dressing wheels, diamond wheels for grinding or cutting

The electroplating process gives the most aggressive, open structure of all bonding methods. This bond type is primarily used in grinding applications. All bonds can be fashioned into any standard or custom shape.