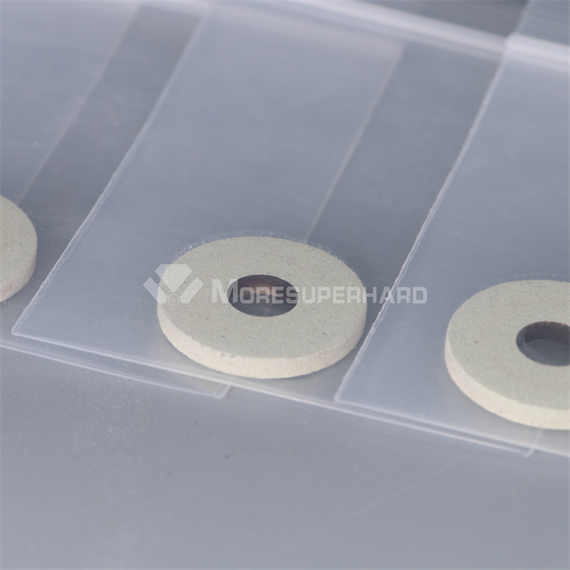

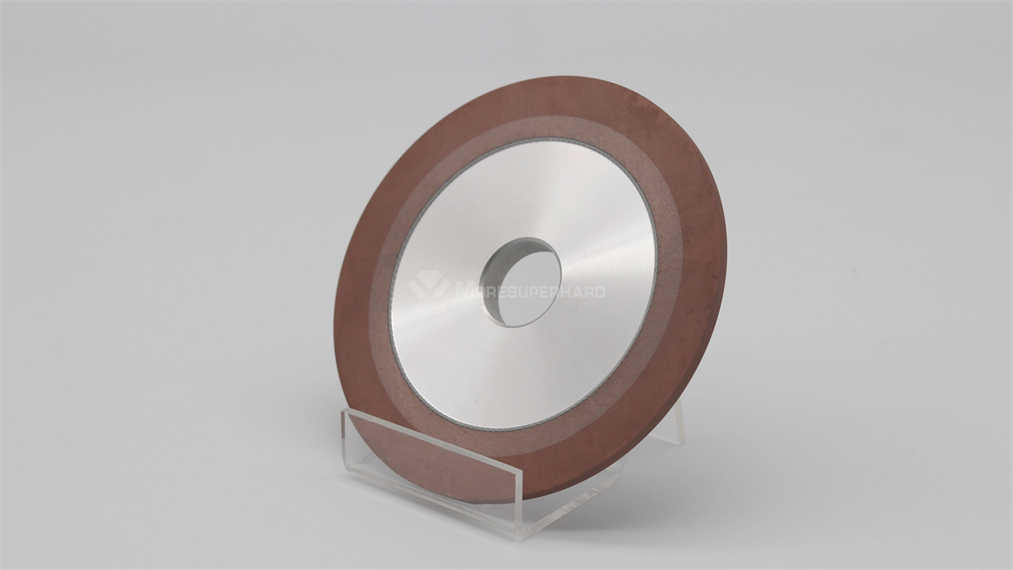

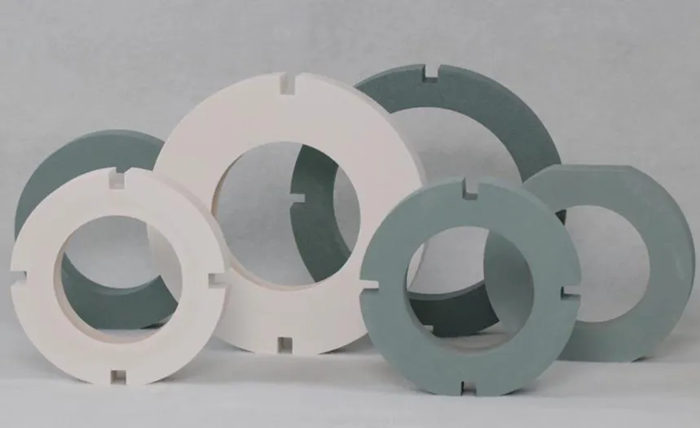

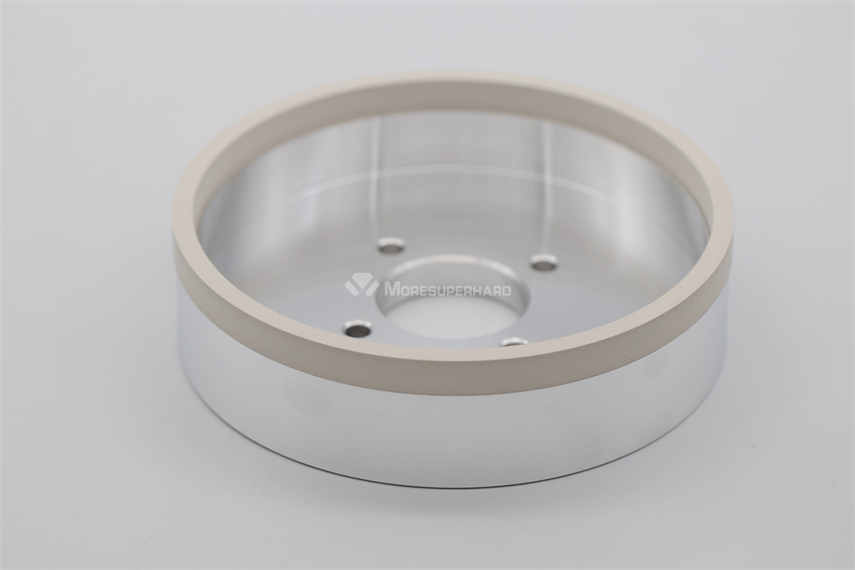

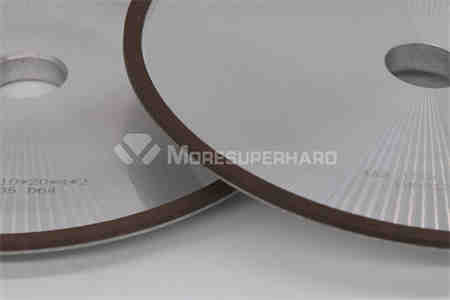

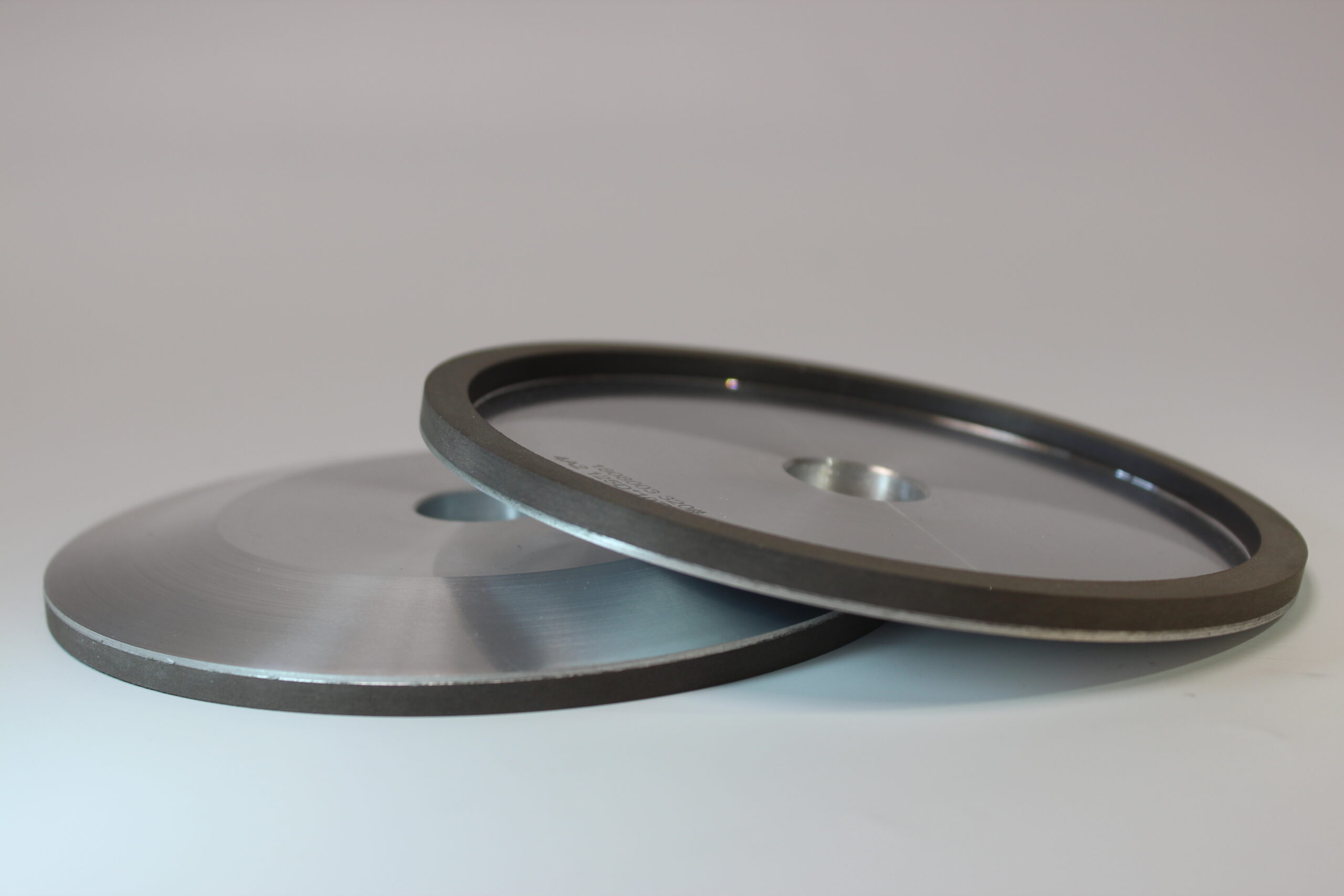

Ceramic CBN Internal Grinding Wheel

Vitrified CBN internal grinding wheels are made of cubic boron nitride abrasives and sintered with metal powder, resin powder and ceramic as a bonding agent to form various shapes of abrasives for industrial grinding, polishing and lapping.

What is the ceramic CBN internal grinding wheel?

Ceramic CBN internal grinding wheels are made of cubic boron nitride abrasives and sintered with metal powder, resin powder and ceramic as a bonding agent to form various shapes of abrasives for industrial grinding, polishing and lapping. This kind of ceramic internal grinding wheel maintains the original high hardness performance of ceramic grinding wheel, low sintering temperature, high strength and toughness, good abrasive holding performance, and has the characteristics of heat resistance, oil resistance, water resistance, acid and alkali resistance, good self-sharpening, dressable and long dressing interval. Uniform porosity for easy cooling, chip removal, etc. It does not block or burn the workpiece in the grinding process, does not cause chemical changes with the Iron group elements, shows its inertia, reduces the fatigue of the workpiece in the grinding process (ID/OD grinding), increases the service life of the workpiece, thus improving the quality, roughness and efficiency of the processed workpiece as well as the automation of the processed workpiece, and achieving the purpose of reducing the comprehensive cost.

What are ceramic internal grinding wheels used for?

1. The grinding of soft steel is preferred. A lot of experience has been gained in grinding imported and domestic stainless steel and other soft steels with very good results, and the efficiency has increased by about 100% and the economic efficiency by 200%.

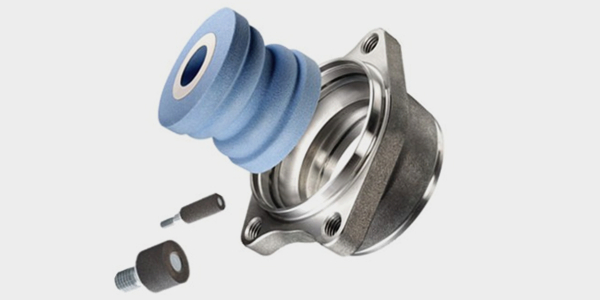

2. Fine grinding and final grinding of workpieces in mass production on automatic machines (miniature bearings, air compressors, crankshafts, camshafts, high-precision threads, instruments, etc.).

3. Grinding of complex profile workpieces (gear shaper, broach, high-precision gear, reliance die, punch, etc.) that require good angle retention of the grinding wheel.

4. Fine grinding and final grinding of large precision workpieces (machine tool guides, high-precision screws, etc.). These workpieces are often deformed due to the high grinding temperature with ordinary abrasives, so the best choice is Xingda CBN grinding wheels.

5. Fine grinding and final grinding of precision parts made of heat-resistant steel and high hardness (HRC55 or above) alloy steel. These parts with ordinary abrasives due to abrasive consumption or grinding dull too fast and can not obtain high precision.

6. Special steel such as Tungsten, Tungsten-molybdenum high-speed steel, Vanadium Alloy steel, Cobalt alloy steel, special high-speed steel tool sharpening, super-finishing of difficult-to-machine heat-resistant steel workpiece, and other steel quenching tool honing.

7. Containing Tungsten, Tungsten Molybdenum and other high-speed steel, especially vanadium alloy steel, cobalt alloy steel and other special high-speed steel tools sharpening and precision.

8. Fine grinding and final grinding of precision parts made of heat resistant, stainless steel and high hardness (HRC55 or above) alloy structural steel. These parts cannot be ground with ordinary abrasives that consume too much or grind dull too fast to obtain high precision.

9. Workpieces in mass production on automatic or semi-automatic machine tools such as instruments and miniature bearing parts.

10. For Titanium Alloy grinding CBN is the best grinding wheel choice.