Vitrified diamond grinding wheels are an important part of the abrasives industry. The abrasive mold industry is becoming more and more important in mechanical production, and grinding wheels have an indispensable role. With the development of science and technology, the growth of new materials, the continuous development of mechanical processing to the direction of high quality, high precision, high efficiency and automation, the application of ceramic bond diamond grinding wheels is more and more extensive, the amount of increase.

What is the vitrified diamond grinding wheel?

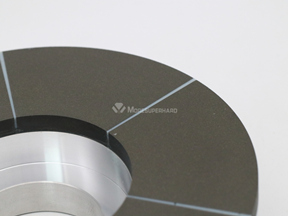

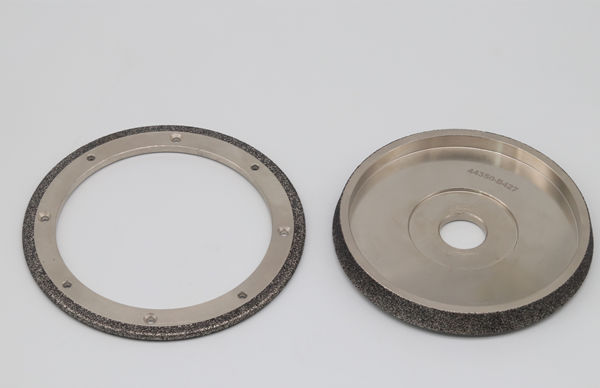

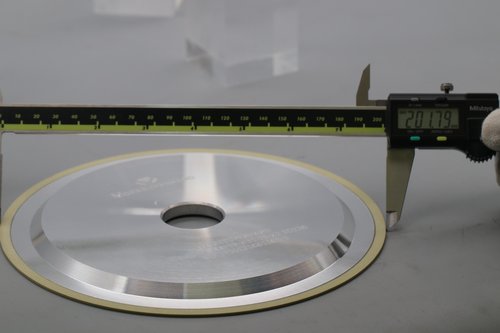

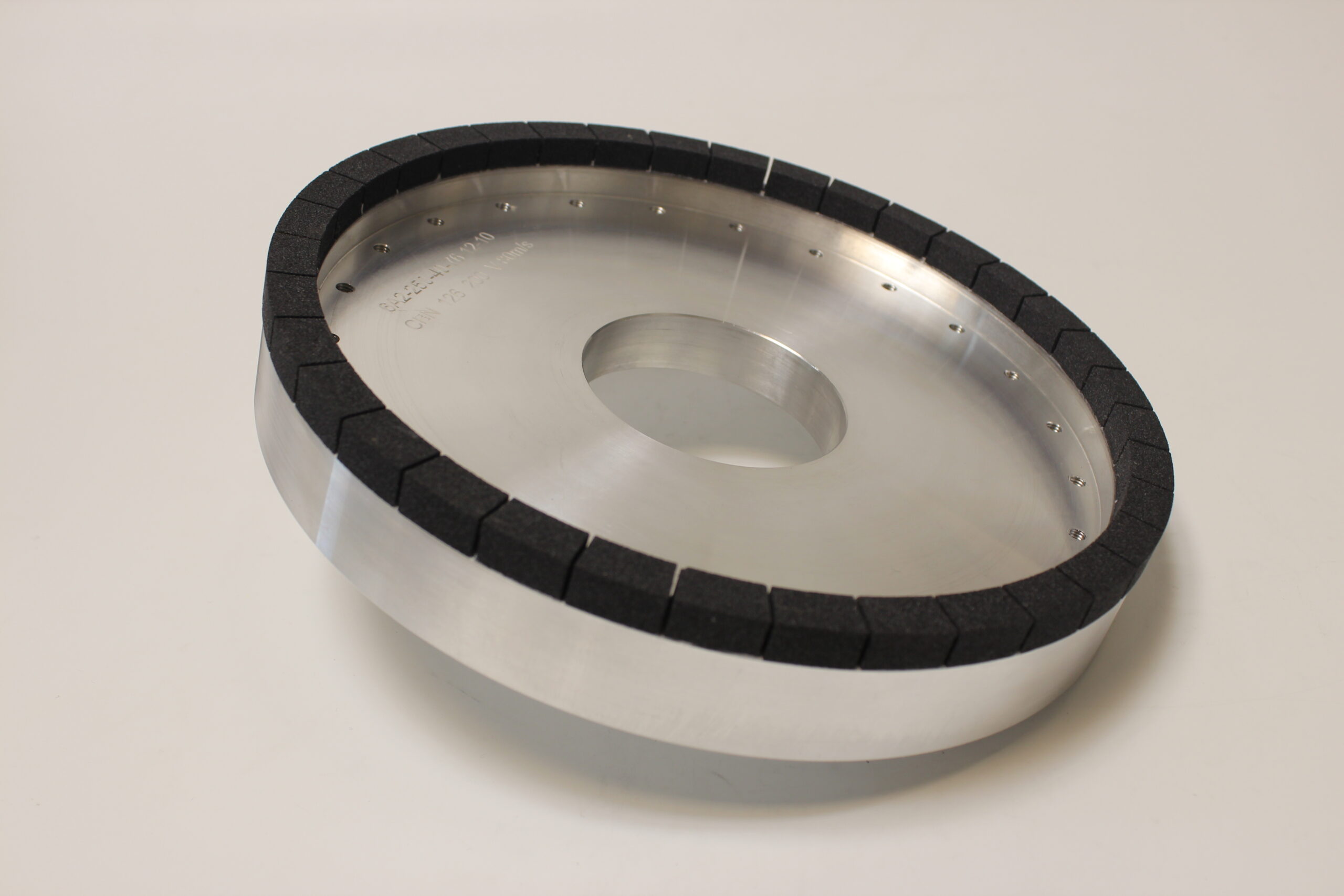

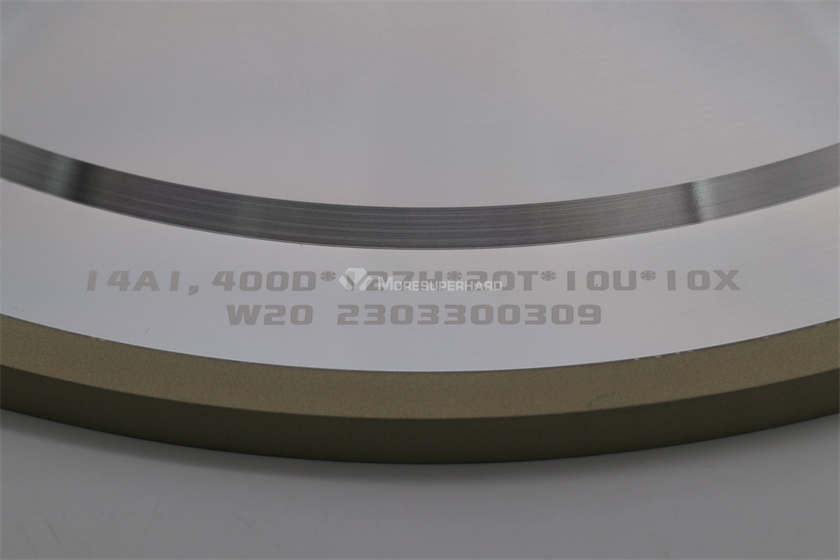

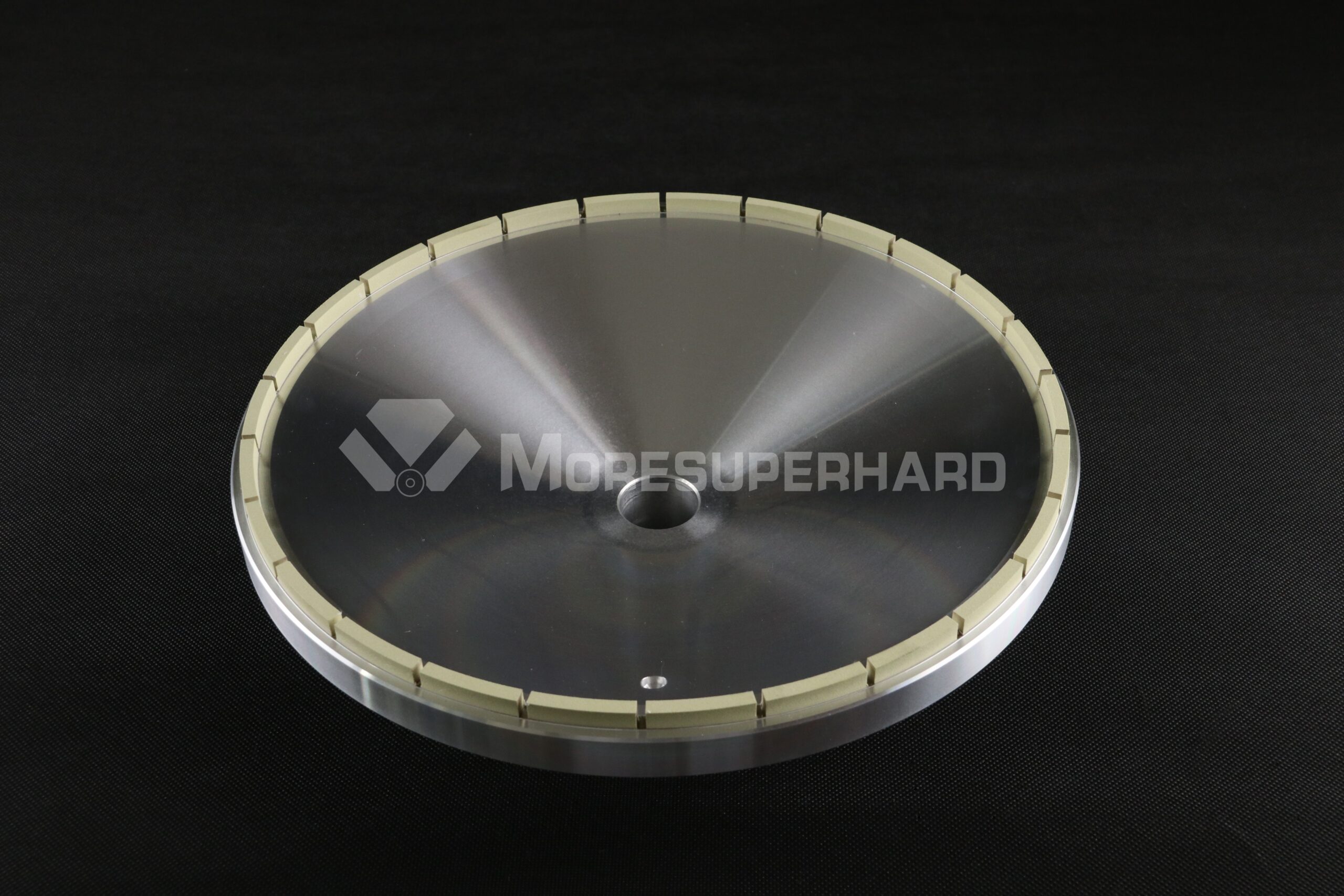

It is made by bonding diamond grains with a well-proportioned ceramic bonding agent, pressing, drying, roasting and dressing, and has many pores, and it is an abrasive tool for cutting with grains. The grinding grain uses the sharp angle of its exposed surface part as the cutting edge

what are the features of the vitrified diamond grinding wheel?

1. high grinding efficiency.

2. high abrasion resistance (high abrasion resistance of the grinding wheel and low abrasive consumption, especially when grinding very hard and brittle workpieces is most obvious).

3. low grinding force and low grinding temperature.

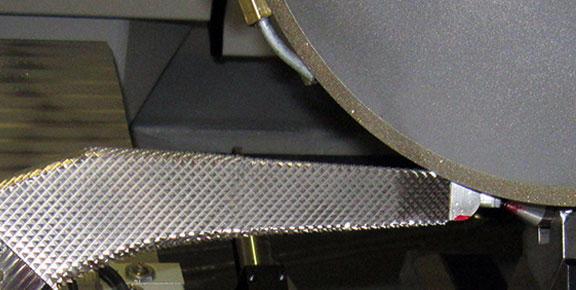

4. High precision and good surface quality of the ground workpiece, and good shape retention of the workpiece.

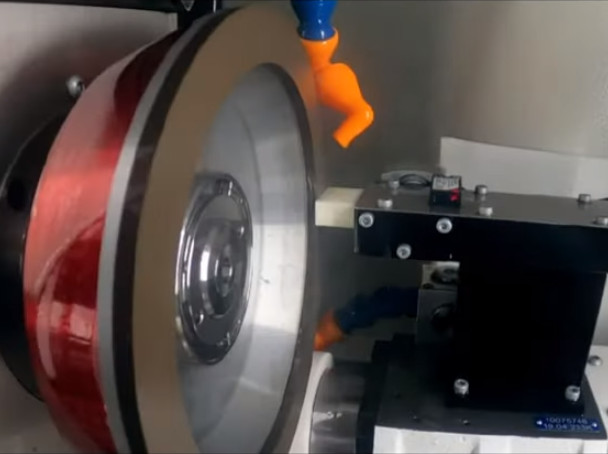

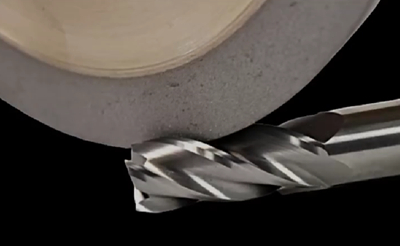

Vitrified diamond grinding wheel combined with the above advantages, as soon as it appears, it is widely used in the mechanical processing of wafers (semiconductor wafers and solar wafers), diamond composite wafers, diamond polycrystalline, diamond tools, cubic boron nitride, tungsten steel (cemented carbide), new engineering structural ceramics, gemstones, crystals, rare earth materials (magnetic materials) and other high hard and brittle materials in developed countries in Europe and America, and has achieved good economic benefits.