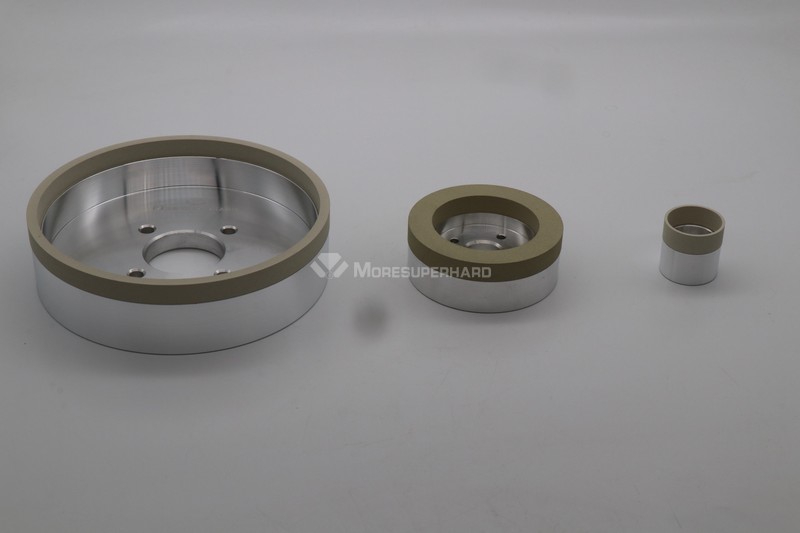

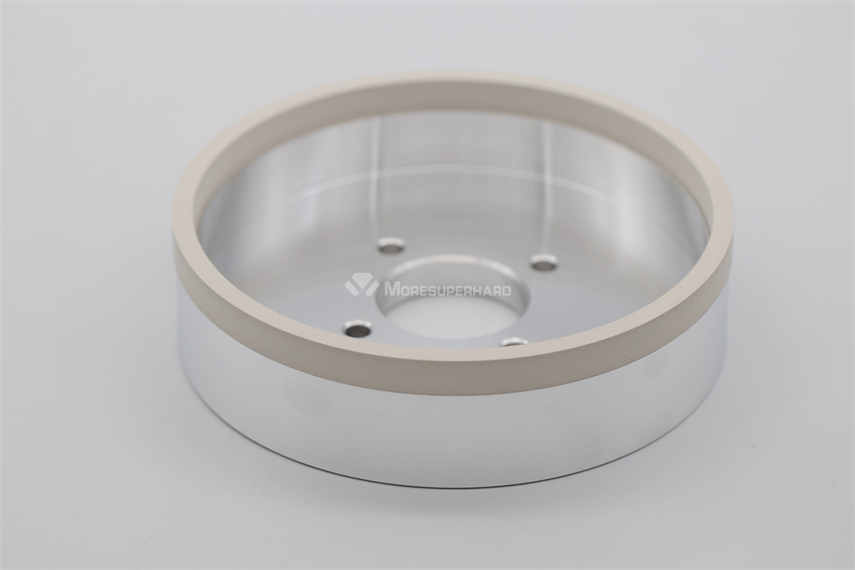

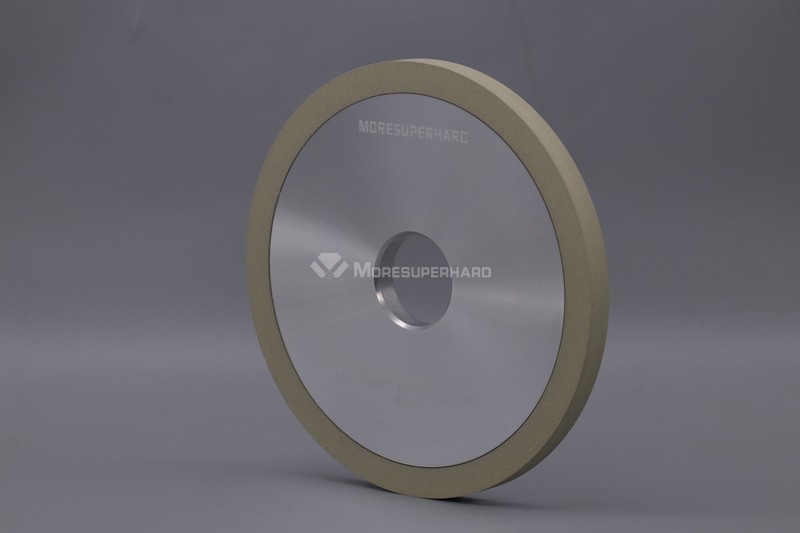

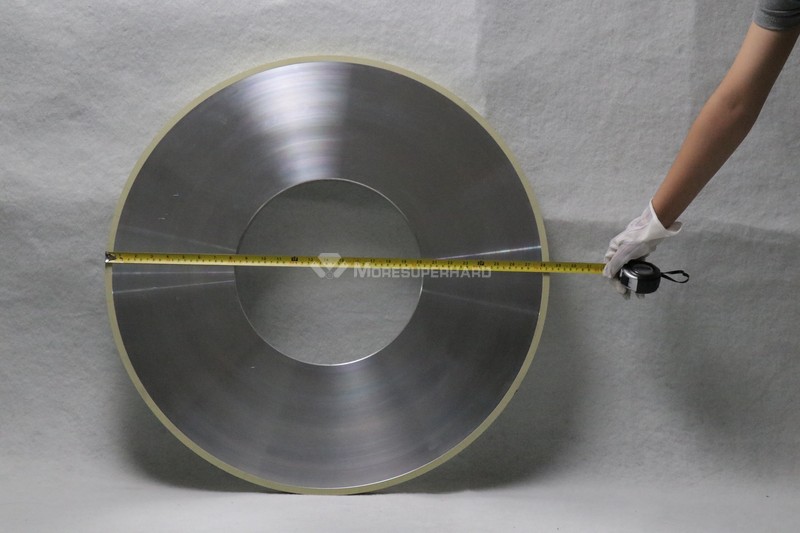

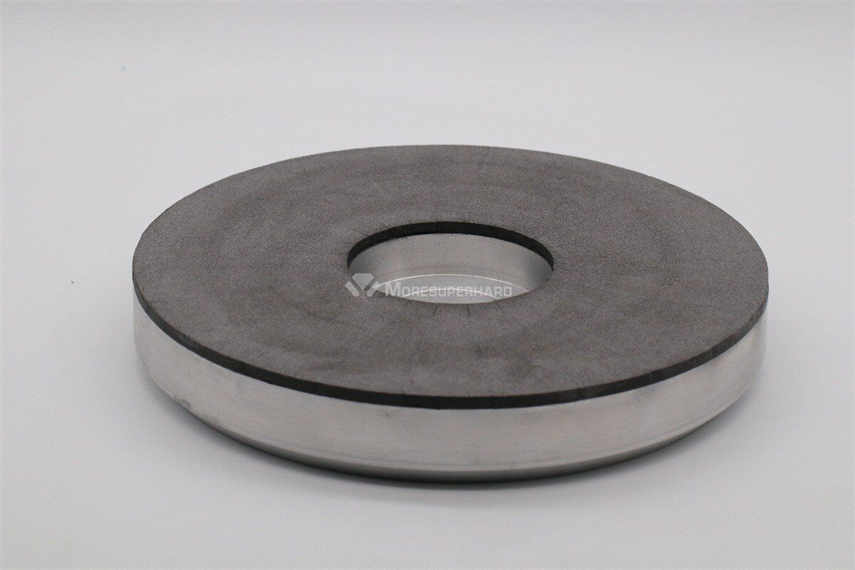

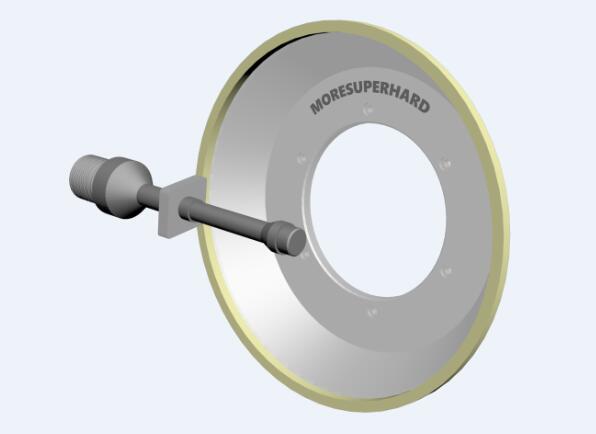

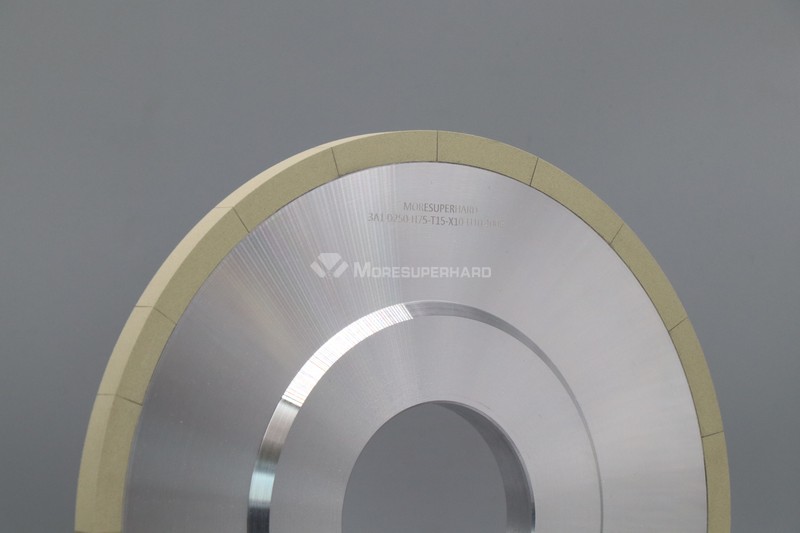

High Precision vitrified bond diamond cylindrical wheel

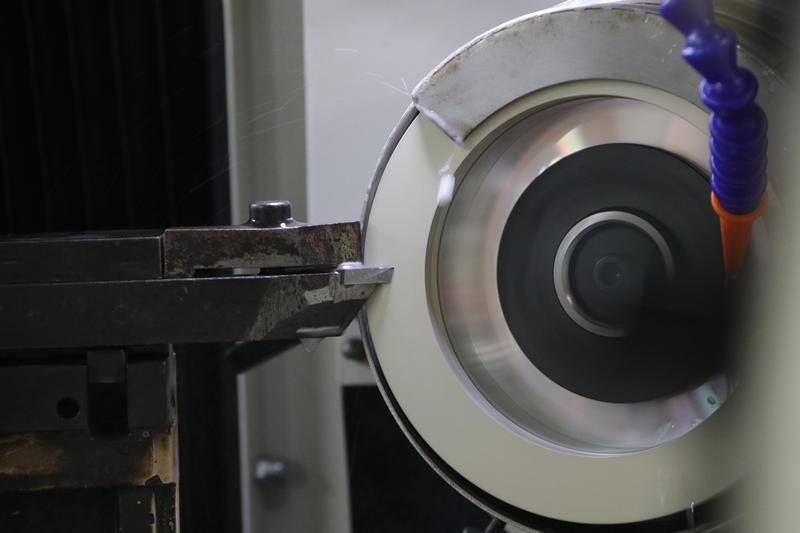

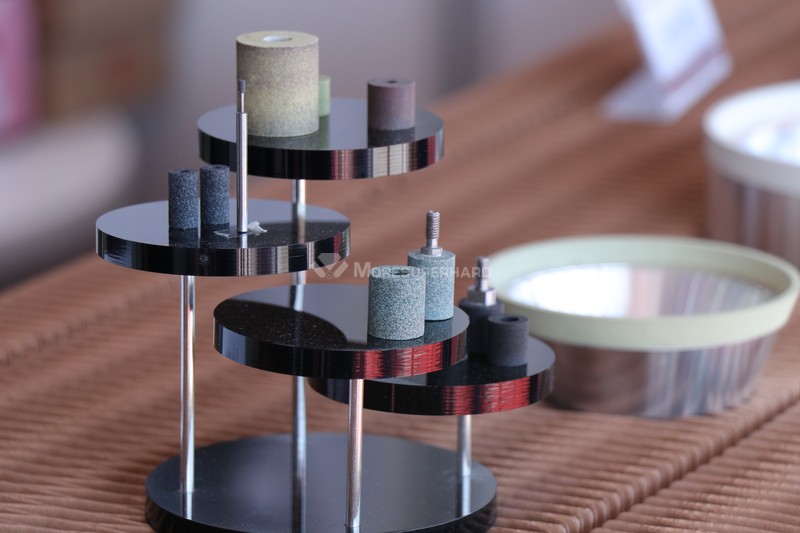

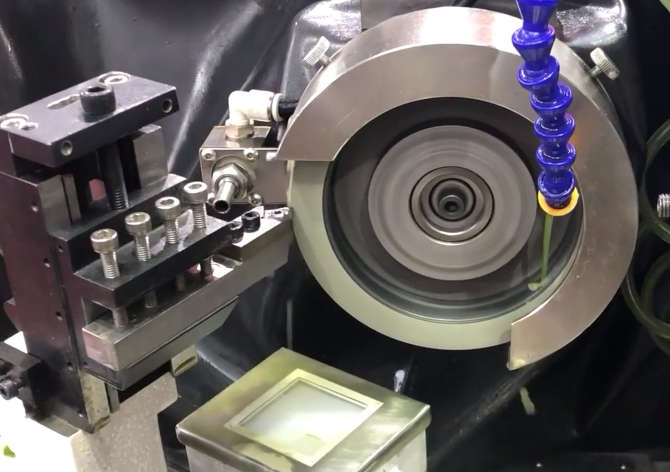

vitrified bond diamond cbn wheels are suitable for surface grinding, OD grinding, centerless grinding, internal grinding, tool grinding, cylindrical grinding and profile grinding, etc

What is Cylindrical Grinding

cylindrical grinding (also called center -type grinding) is used to grind the cylindrical surface and shoulders of the workpiece. There are five different types of cylindrical grinding: outside diameter (OD) grinding, inside diameter (ID) grinding, plunge grinding, creep feed grinding, and centerless grinding. The various grinding methods include straight cylindrical, taper, end face, and total shape grinding.

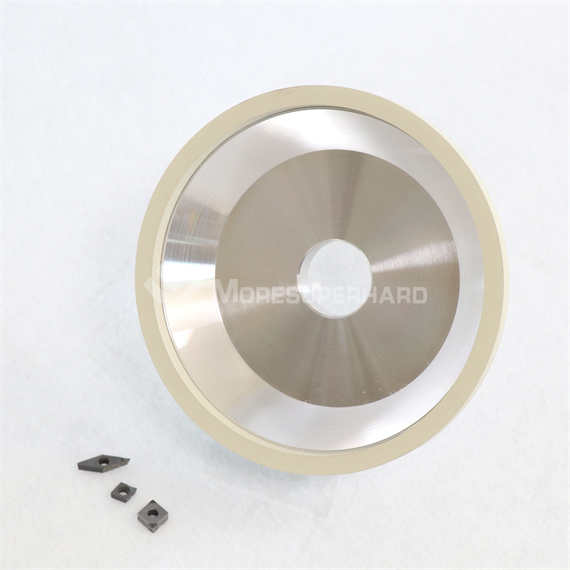

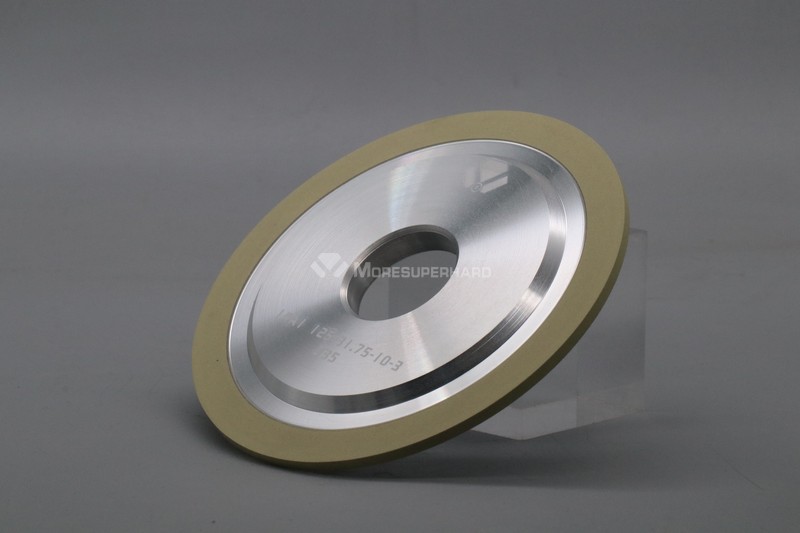

Vitrified bond diamond wheels compared with resin bond and metal bond

Bond is a kind of material with high bonding ability. Vitrified bond can bond the diamond grains together and play the role of connecting and fixing.

Bond usually has high strength and good heat resistance, and also has proper hardness. The surface roughness of the bond is good, and the filler is economical and the grinding efficiency is high.

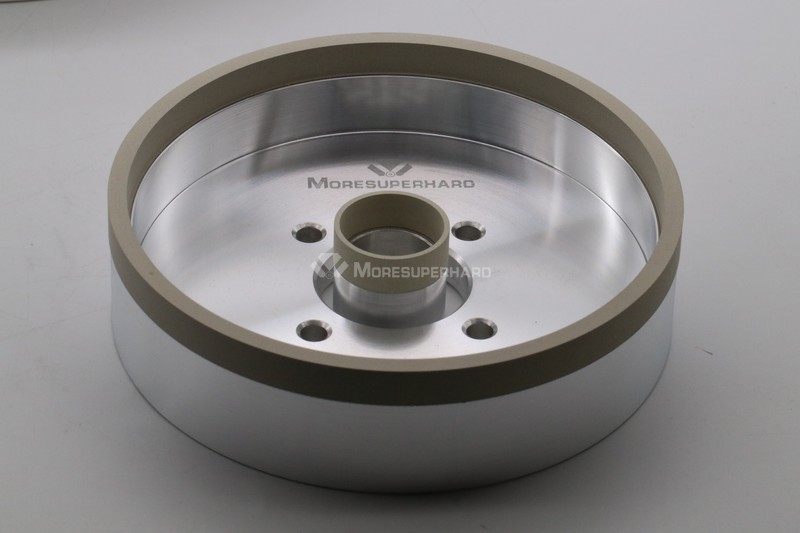

Applications of vitrified bond diamond cylindrical wheels

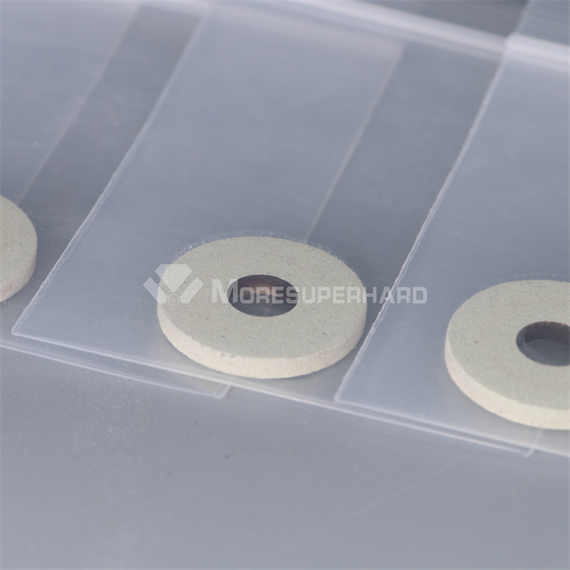

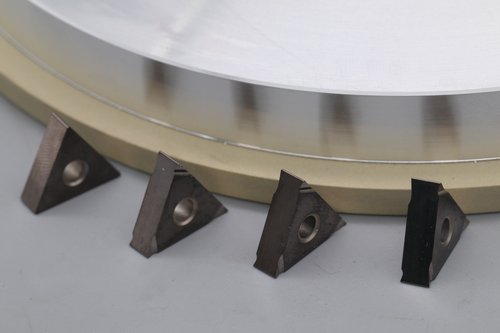

Vitrified bond diamond grinding wheel is used for rough grinding, finish grinding and super-finish grinding of ceramic sleeve pin for optical fiber and telethon.

Grinding silicon wafer, silicon carbide, silicon nitride, and other engineering ceramic, etc