Diamond /cbn internal wheels grinding heads manufacturer

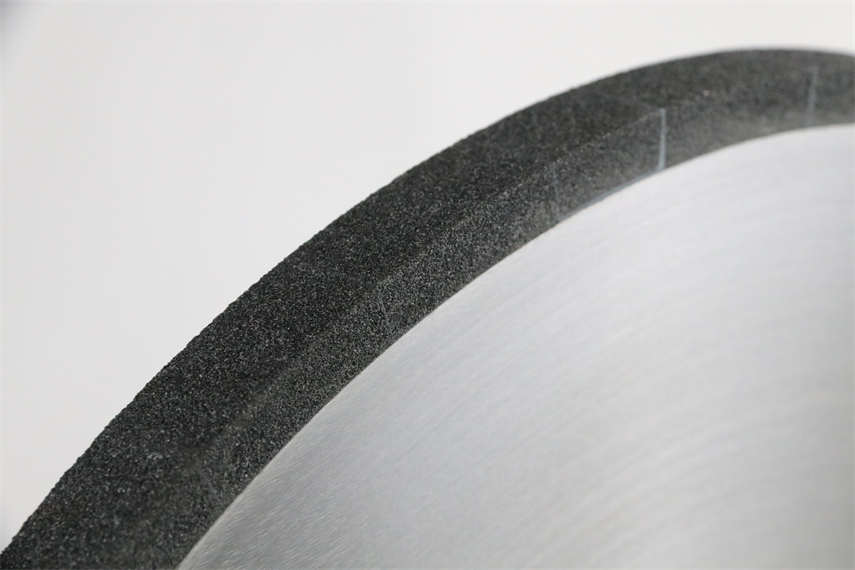

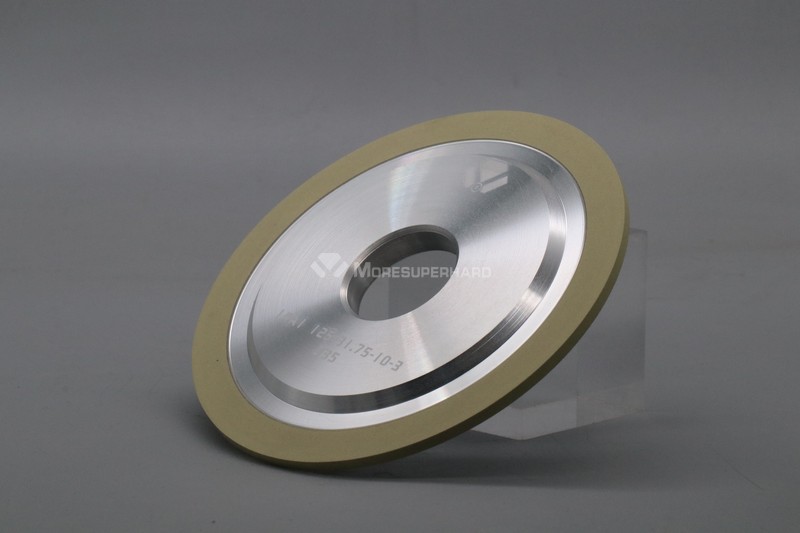

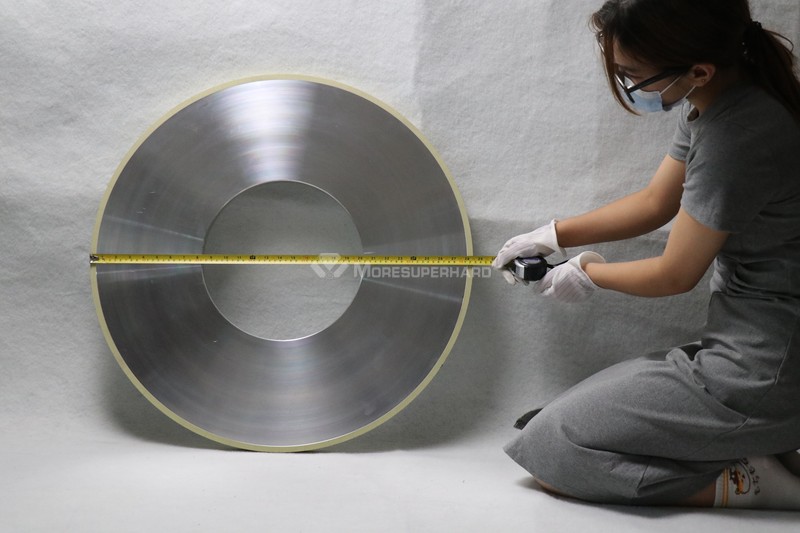

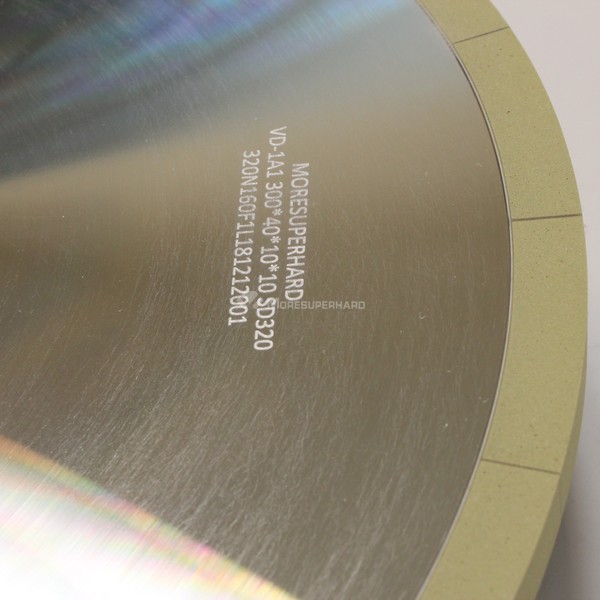

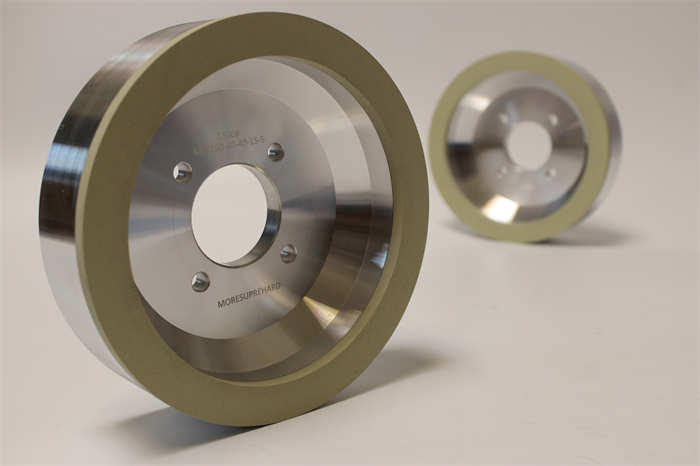

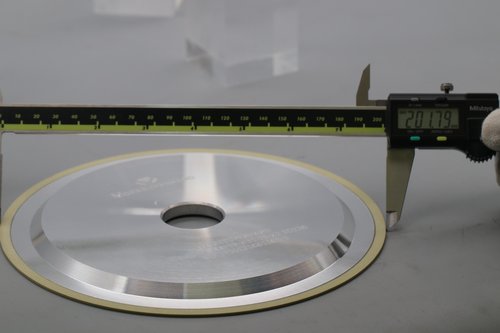

Diamond and CBN (cubic boron nitride) internal grinding wheel produced by moresuperhard’s factory can achieve a small diameter of 1.5 mm, and the wear resistance is very good, and there is no need to frequently trim the outer circle. Batch processing of small holes of parts can ensure the consistency of roundness, perpendicularity and diameter tolerance accuracy, high temperature resistance during the grinding operation, and no burns on the workpiece and the grinding wheel.

Grease grinding fluid must be added during the grinding process To cool down and remove chips (tap water can not be added directly, tap water will carbonize the high-temperature grinding CBN raw materials), to avoid the large amount of metal scrap generated during the grinding process from squeezing the hole wall of the workpiece and blocking the pores on the surface of the cubic boron nitride grinding head .

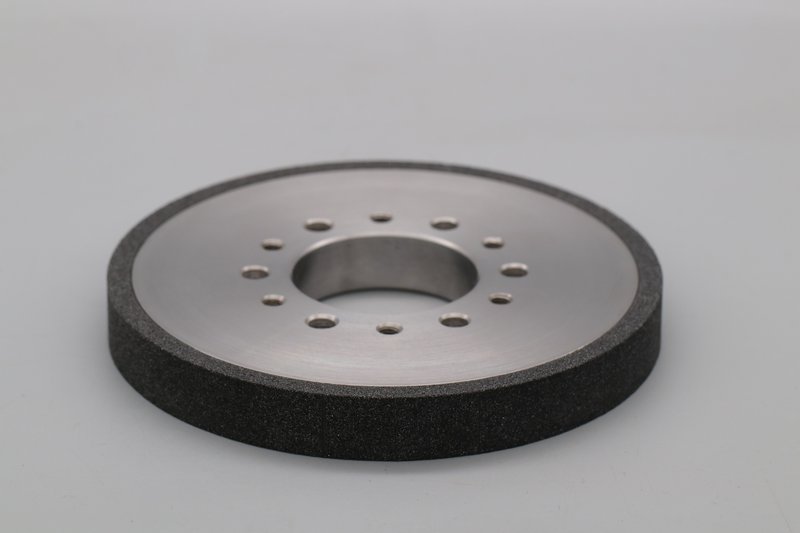

Diamond /cbn internal wheels

Processing HRC35-HRC70 degree steel parts (20 chromium steel, 40 chromium steel, tool steel, die steel, bearing steel, alloy steel, structural steel, high-speed steel, ductile iron, heat-resistant steel, titanium alloy, 38 chromium molybdenum aluminum, special Structural steel, etc.) Customized production of diamond/CBN internal grinding wheels and grinding heads for grinding small holes.

Parts with small holes within 5 mm in diameter require heat treatment or nitriding treatment before grinding to increase the hardness of the surface of the part, and enhance the wear resistance and compression resistance. According to different requirements, the hardness will be controlled between HRC35-HRC55 degrees, and there are also special requirements that the hardness will reach HRC70 degrees or more after treatment. The deformation of the parts after heat treatment or nitriding (also ** is the amount of grinding) is generally between 0.10mm and 0.15mm.

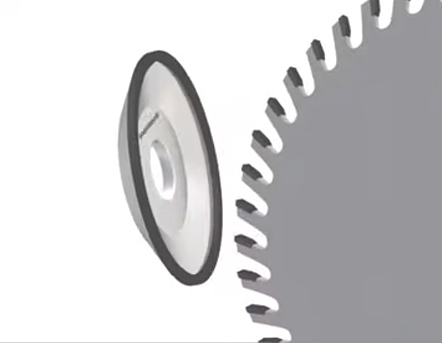

The diameter of the workpiece hole is small and the hardness is high. These two characteristice cause the difficulty of grinding. Users usually buy small grinding wheels of white corundum, brown corundum or green silicon carbide for internal grinding.

The advantages of these three materials of grinding wheels (also called grinding heads) are that they are cheap and easy to trim the outer circle after bonding with the tool holder (small diameter of about 6 mm, like grinding the inner hole of 3 mm, the outer diameter needs to be repaired to 2 mm Can only be used), Diamond /cbn internal wheels is very easy to repair with artificial metal pens or natural gold fountain pens. But the shortcomings are also obvious. The grinding loss is very fast. The inner hole of the part cannot guarantee the accuracy (there is a bell mouth, one hole is large and the other is small), and the outer circle needs to be frequently trimmed to work, which is time-consuming and labor-intensive.