The differences between electroplated diamond film belt and resin diamond film belt

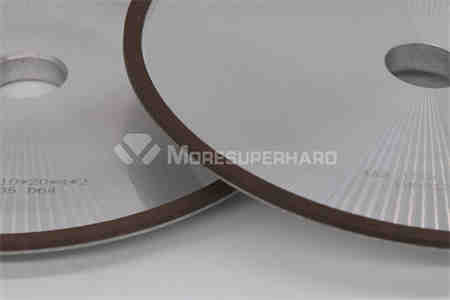

► Bond: Metal nickel plating electroplated bond & Resin bond (resin bond also consists of flexible and hard type)

► Length: 150mm – 5000m

► Width: 5mm – 350mm

► Grit: #60,#100,#120,#200,#400,#800,#1500,#2000,#3000,#5000

What is the difference between electroplated diamond abrasive belt and resin diamond abrasive belt?

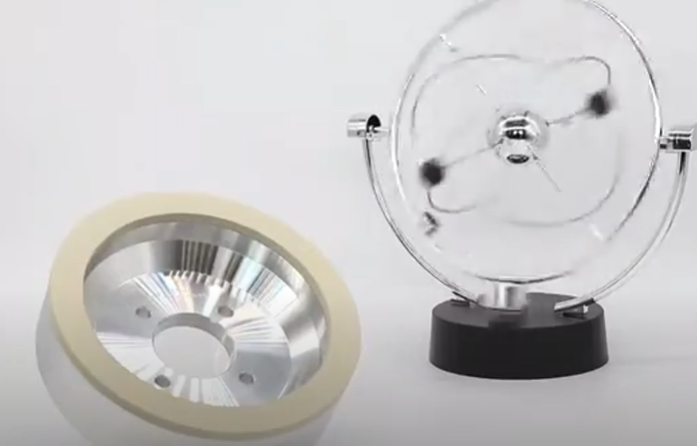

1. In terms of bond, resin diamond abrasive belt mainly uses phenolic resin and a small amount of metal powder as the bond, while electroplated diamond abrasive belt is a kind of abrasive belt production process that deposits nickel drill alloy on the surface of metal matrix and fixes diamond abrasive by electrodeposition.

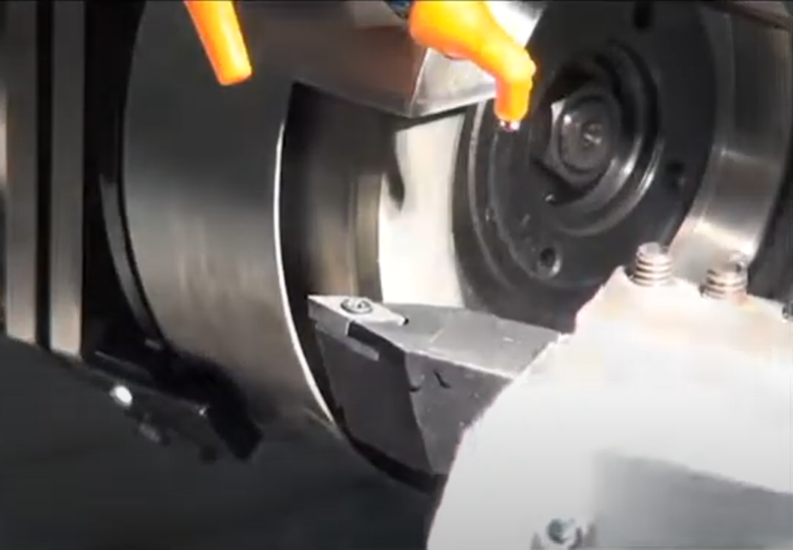

2. In terms of processing efficiency, because the electroplated diamond abrasive belt uses higher-grade abrasive and has only one layer of abrasive, it has its own advantages in heat dissipation performance, so the processing efficiency of the electroplated diamond abrasive belt is higher.

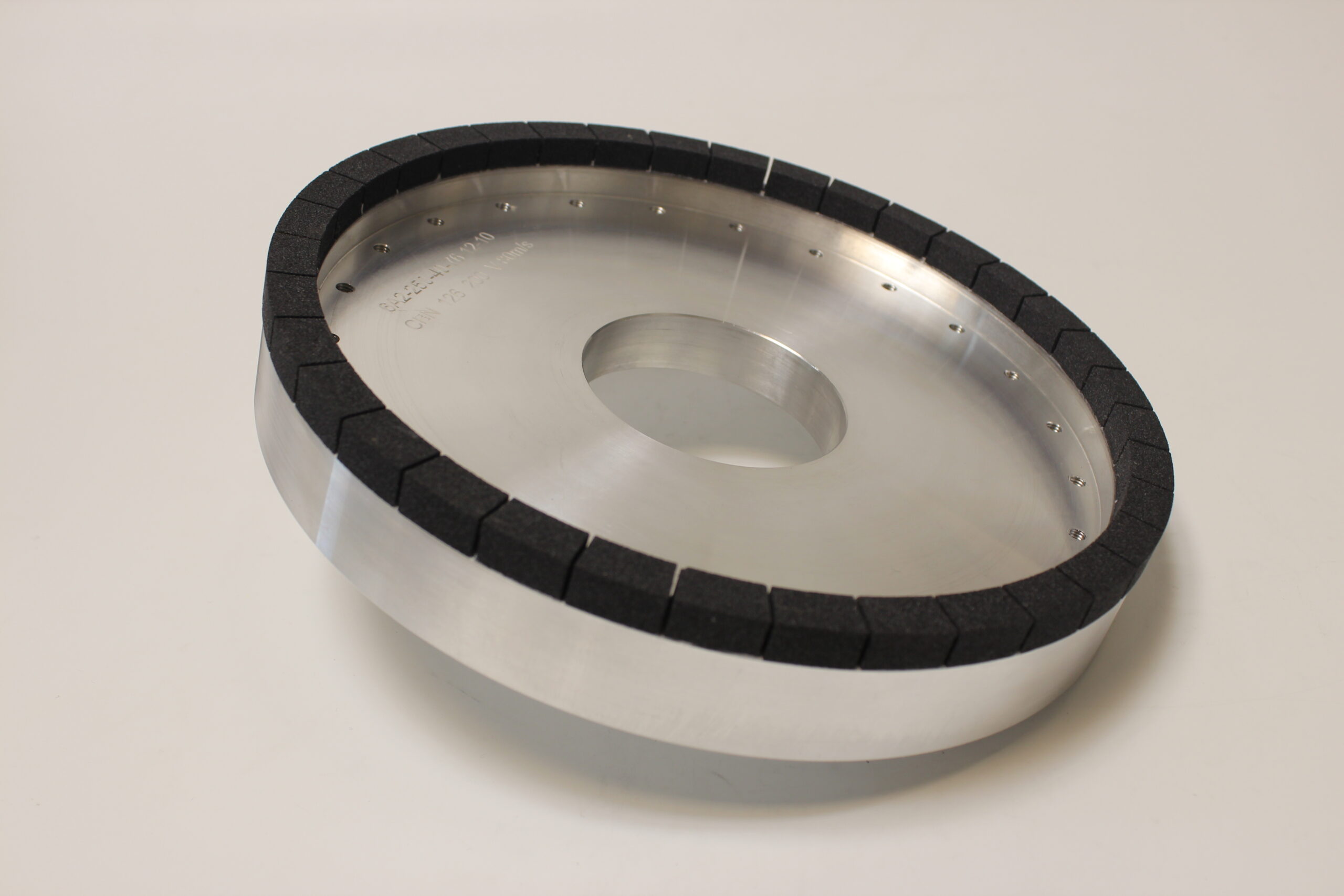

3. In terms of service life, the electroplated abrasive belt has only one layer of abrasive, so the service life of the electroplated abrasive belt is inferior to that of the resin diamond abrasive belt.