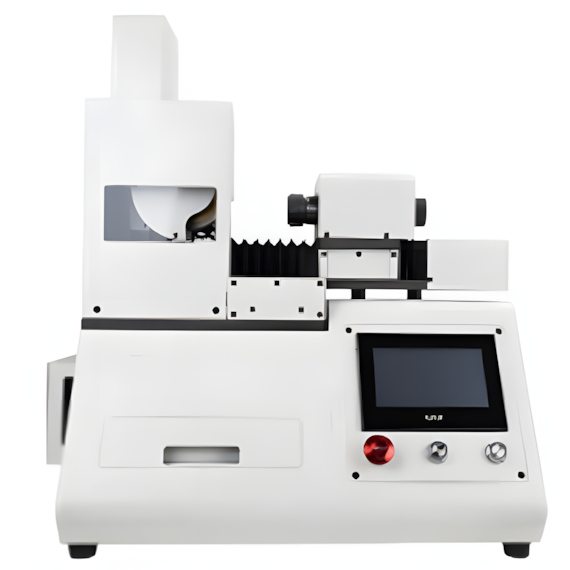

High Precision Conventional Cylindrical Grinders

Cylindrical Grinder Accessories

– Precision Spindle

– V and flat guide rail

– C3 Ball Screw

– Precision hand shovel

– Roller grinding wheel corrector

Conventional cylindrical grinding machine is designed for the grinding of workpieces in single-component or small series production runs. Cylindrical grinder is suitable for use in any industry where precise small components are manufactured.

New Design Concept Of Machine Structure

The frame structure is made of Meehanite cast iron and has a low center of gravity design.With the latest finite element computer-aided analysis, the rigid design is above 108N / m and the lowest natural frequency is designed above 150Hz. This outstanding structural design makes the machine fully shock-proof and shock-absorbing, ensuring its high rigidity and maximum damping performance, thus extending the life of the machine.

Operating Plate Displacement And Feed Mode

The left and right displacement of the operating plate and the grinding wheel head are all manually operated.The operating plate is driven by the oil pressure, and the grinding wheel head is fed manually The operating plate is driven by the oil pressure, the grinding wheel head is fast forwarded and fast-returned, and the feed is manually operated.The operating plate is driven by the hydraulic pressure, the grinding wheel head is fast forwarded and fast-returned, and the feed is automatically operated.Install automatic positioning device.