How to choose electroplated diamond film belt and resin diamond film belt

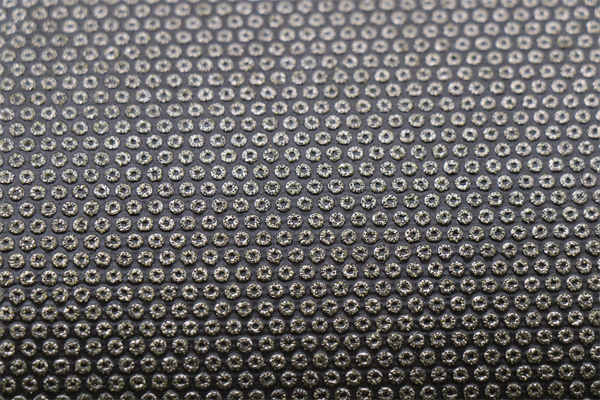

► Bond: Metal nickel plating electroplated bond & Resin bond (resin bond also consists of flexible and hard type)

► Length: 150mm – 5000m

► Width: 5mm – 350mm

► Grit: #60,#100,#120,#200,#400,#800,#1500,#2000,#3000,#5000

Advantages of electroplated diamond belts:

1. Electroplating process is simple, investment is small, and production is convenient

2. Easy to use.

3. The single-layer structure determines that it can reach a high operating speed

4. Although there is only a single layer of diamond, it still has enough life.

Shortcomings of electroplated diamond belts:

1. There is no strong chemical metallurgical bonding between the coated metal and the substrate and the abrasive interface. The abrasive is actually only mechanically embedded in the coated metal, so the operating force is small, and the diamond particles are heavily loaded. Efficient grinding is easy to fall off (or the coating falls off in pieces), resulting in overall failure.

2. In order to add control force, it is necessary to add coating thickness. As a result, the exposed height of abrasive particles reduces the chip space, the abrasive belt is easy to block, the heat dissipation effect is poor, and the workpiece surface is easy to burn.