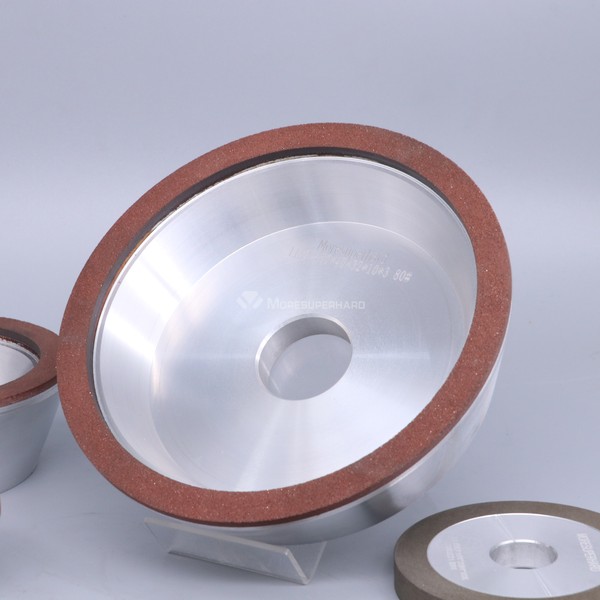

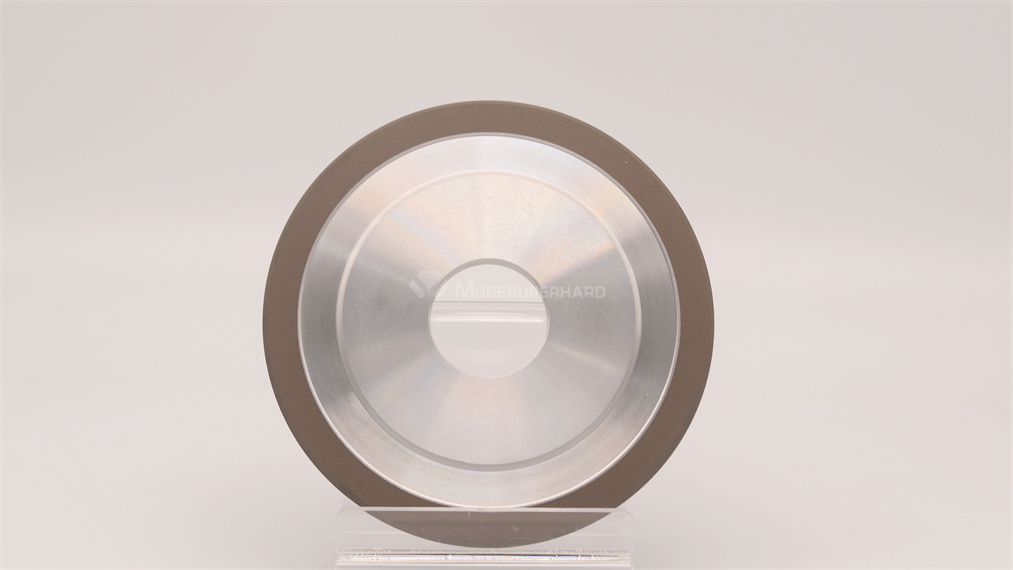

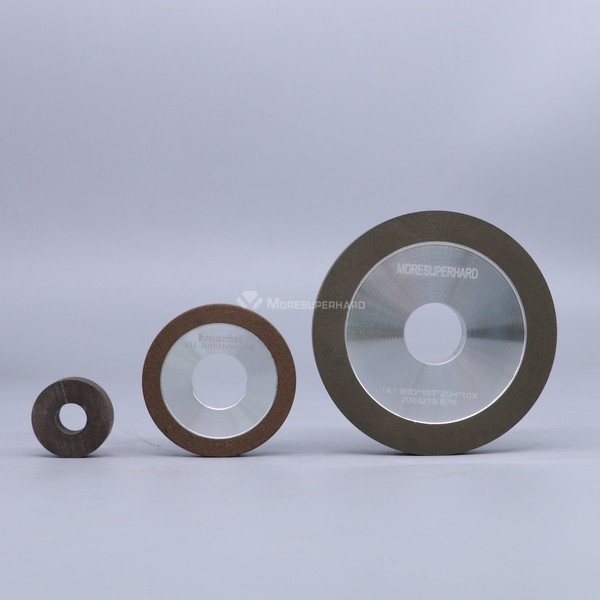

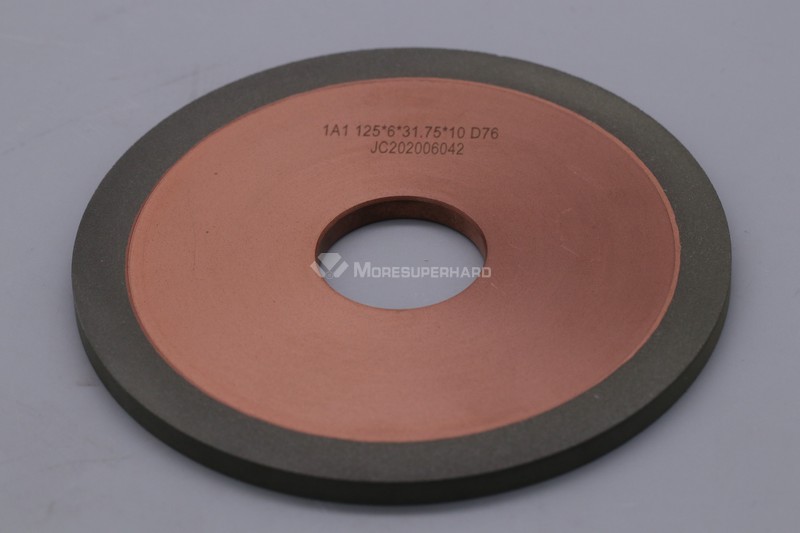

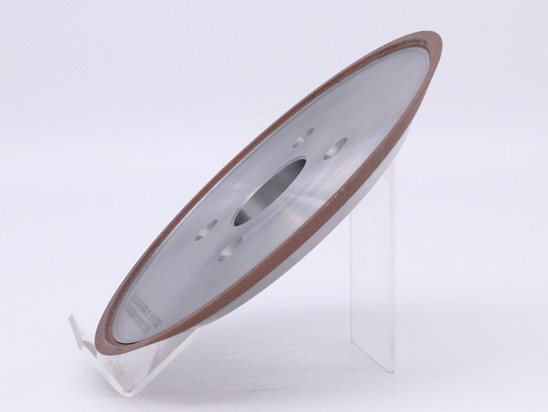

Resin bonded diamond grinding wheel for tungsten carbide

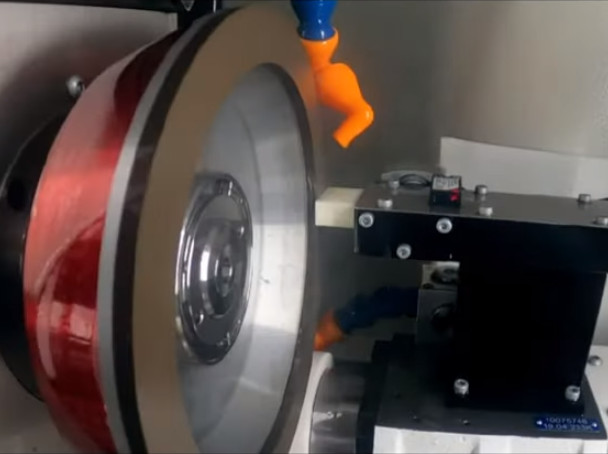

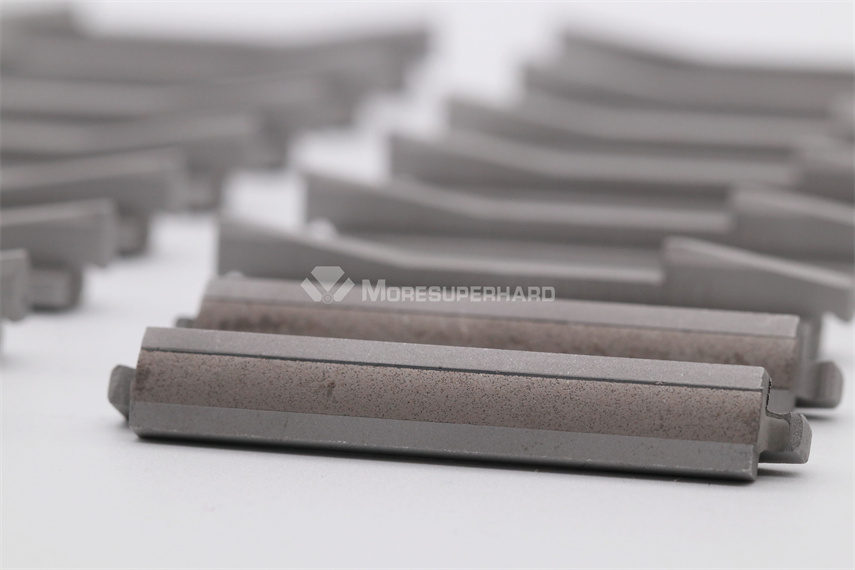

Resin bonded diamond grinding wheels applied to coarse grinding and finish grinding for metal materials, such as PCD and PCBN workpiece and tools, high speed steel, high vanadium steel, stainless steel, steel and hard alloy.

For finishing grinding, polishing and ultra-finish grinding stage processing nonmetallic hard and brittle materials such as glass, stone, ceramics, gem, magnetic, etc.

Application Resin bonded diamond grinding wheel

Resin bond cbn grinding wheel, with high hardness, high strength, strong grinding capability, is mainly used for cutting and grinding alloy, non-metallic materials, such as hard alloy, ceramics,agate, optical glass, semiconductor materials and wear resistant cast iron ,stone etc. With different cbn grits.

Features Resin bonded diamond grinding wheel

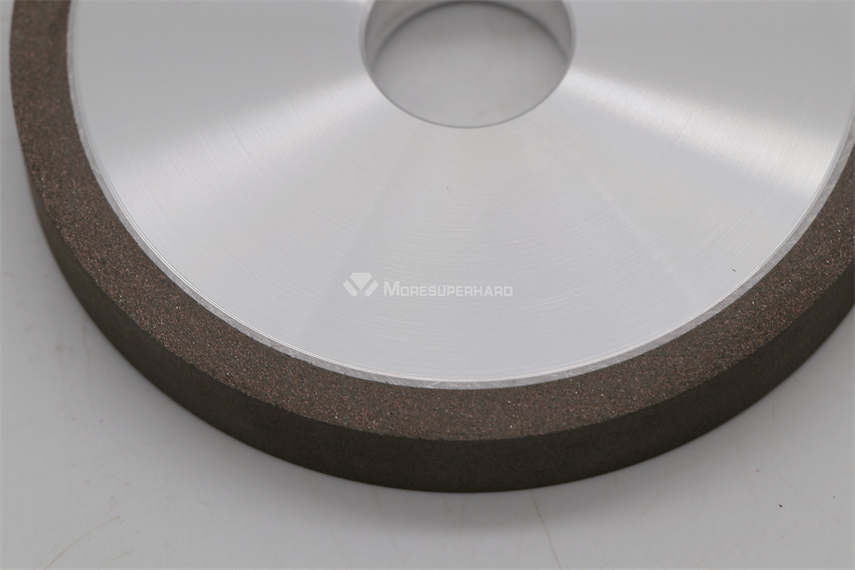

High grinding efficiency, low grinding force: less heat will be generated by the hole in the grinding process. This can decrease or avoid bums and cracks on the surface of the workpiece, and decrease the equipment’s wear and energy consumption.

High wear resistance: grinding cbn wheels’ change in dimension is small. This can lead to good grinding quality and high grinding precision.

Long lifespan, long dressing period: this can greatly increase the work efficiency, and improve the workers’ labor environment and decrease the product’s labor intensity.

Low comprehensive cost : the processing cost of each workpiece is lower.