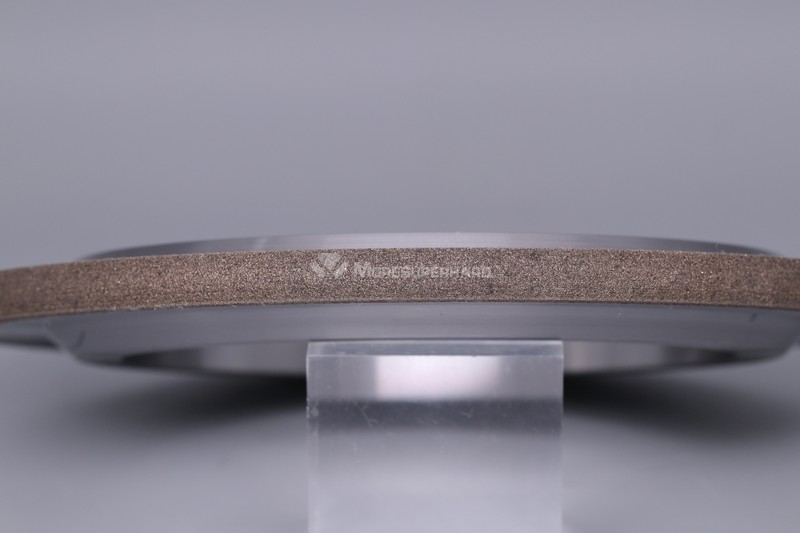

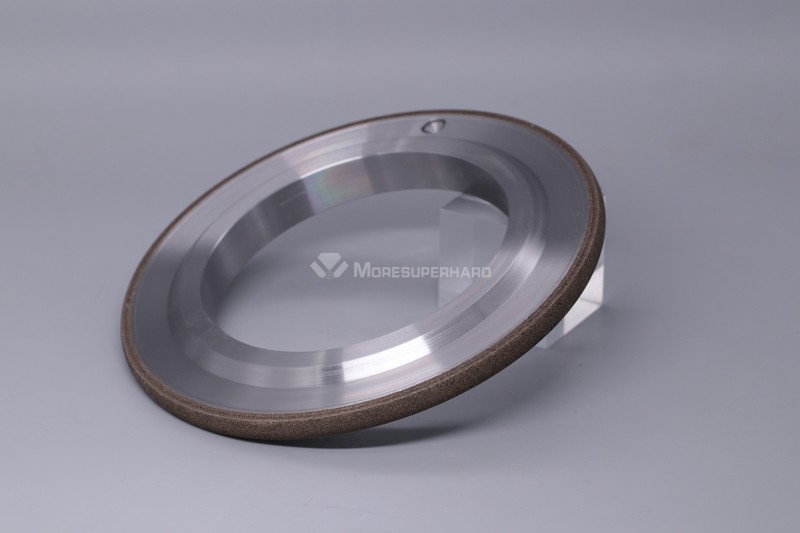

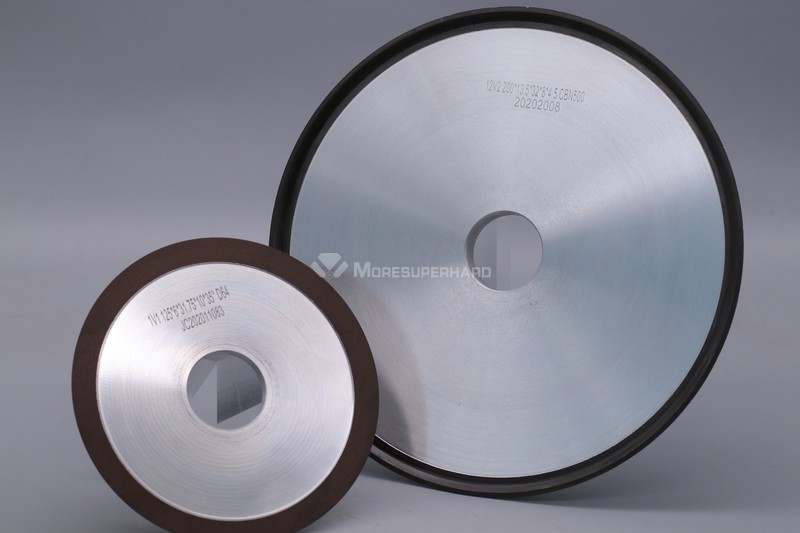

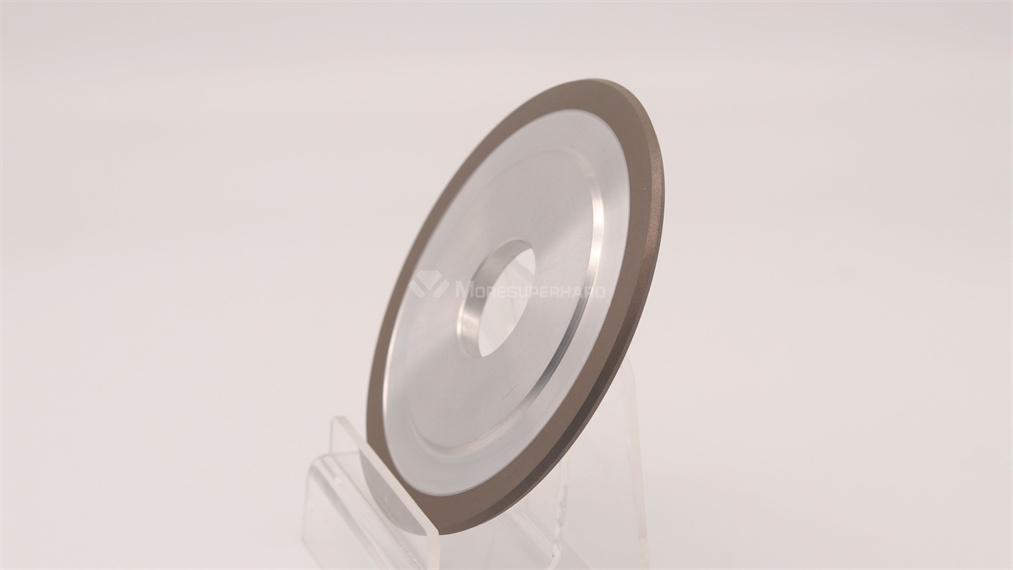

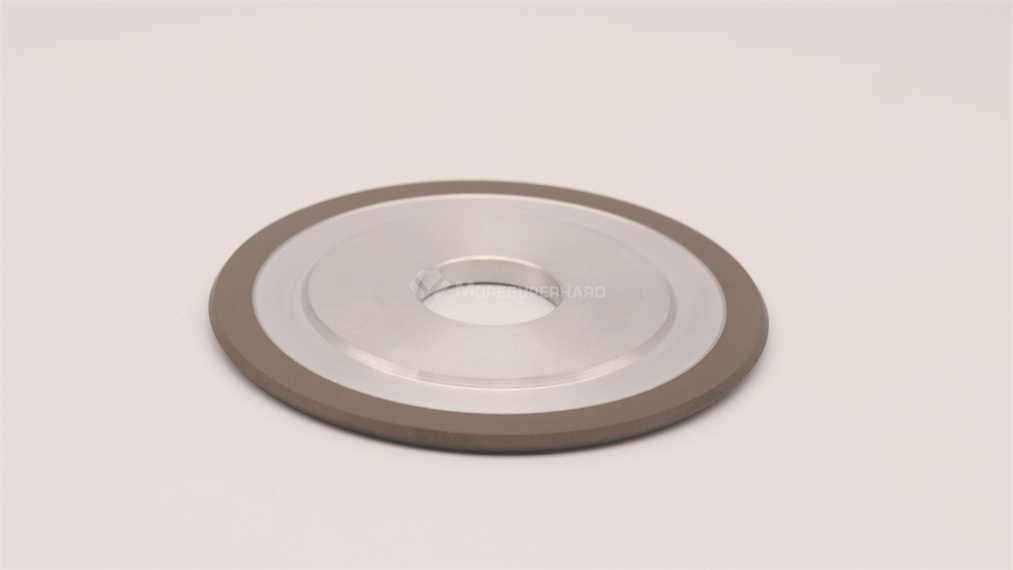

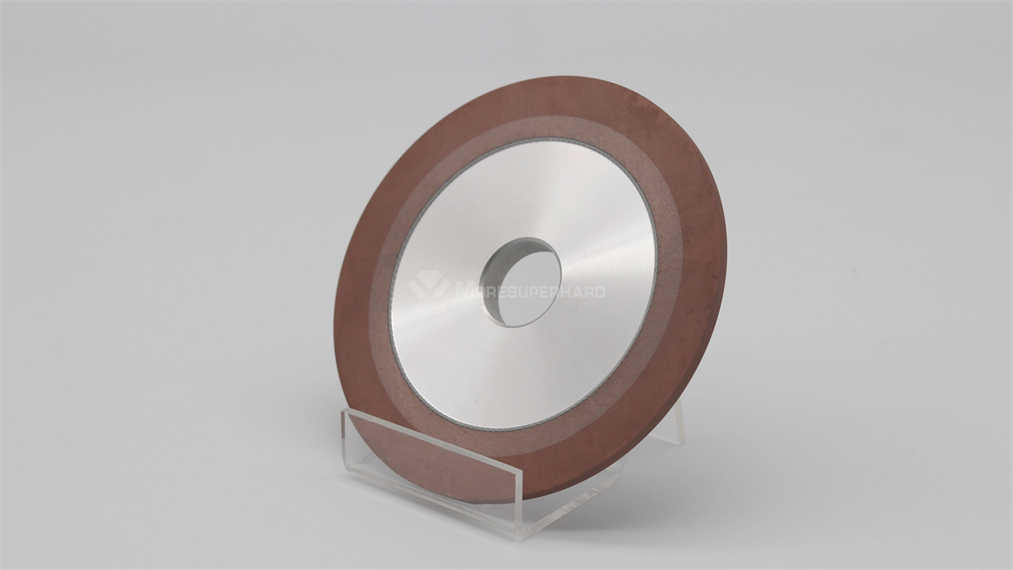

Resin bonded diamond grinding wheel factory

Resin bonded diamond grinding wheel

• For grinding tungsten carbide and steel materials

• High material removal volumes at low grinding forces

• For wet and dry grinding

• High flexibility by mixing in suitable additives

• For fine grinding operations

Diamond resin grinding wheel has high hardness, high strength and strong grinding ability. It is mainly used for grinding high and hard alloys, non-metallic materials, cutting hard and brittle hard alloys, and non-metallic minerals. Such as cemented carbide, ceramics, agate, optical glass, semiconductor materials, wear-resistant cast iron, stone, etc.

Cubic boron nitride (CBN) resin grinding wheels are mainly used for grinding brittle and hard metal materials: ① high manganese steel, high carbon steel, stainless steel, die steel, bearing steel; ② high chromium, nickel, molybdenum and other heat-resistant and high-hardness alloy steels ③Chilled cast iron (HS80~90); ④Various types of hardened steel (HRC55~65); ⑤Various types of cast iron (HB200~400), etc., and have been processed in domestic automobiles (gears, flywheels, shafts, bearings, etc.) , Rolls, slurry pumps (impellers, volutes, guard plates, sheaths, etc.), molds, cylinder liners; it solves the cutting processing of high-hardness and difficult-to-machine materials in various industries, and can improve work efficiency and greatly save Processing man-hours and electricity have obtained huge economic benefits.

The diamond (CBN) resin grinding wheel has a good polishing effect. The grinding wheel is sharp and not easy to be blocked during grinding.