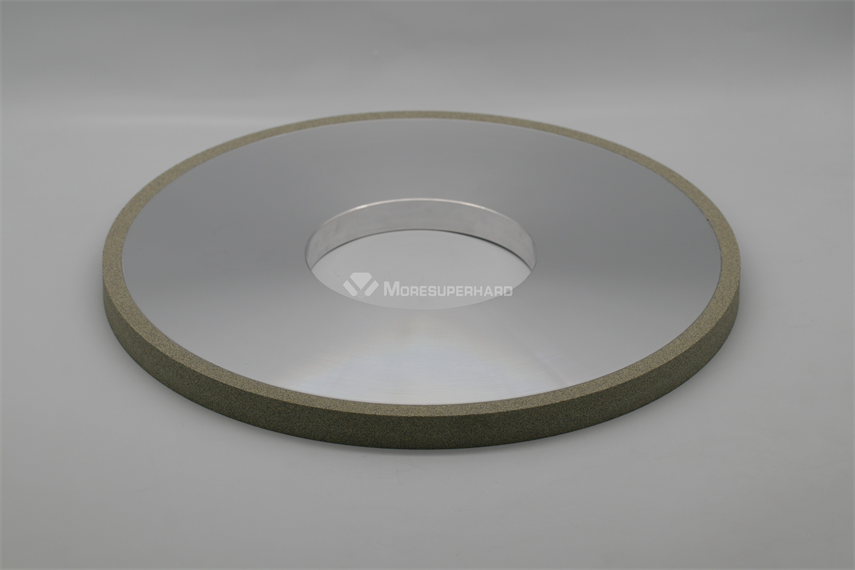

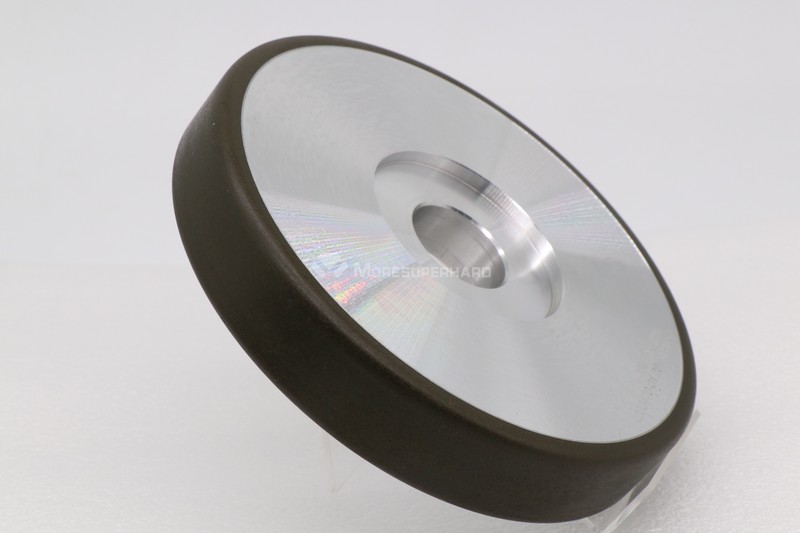

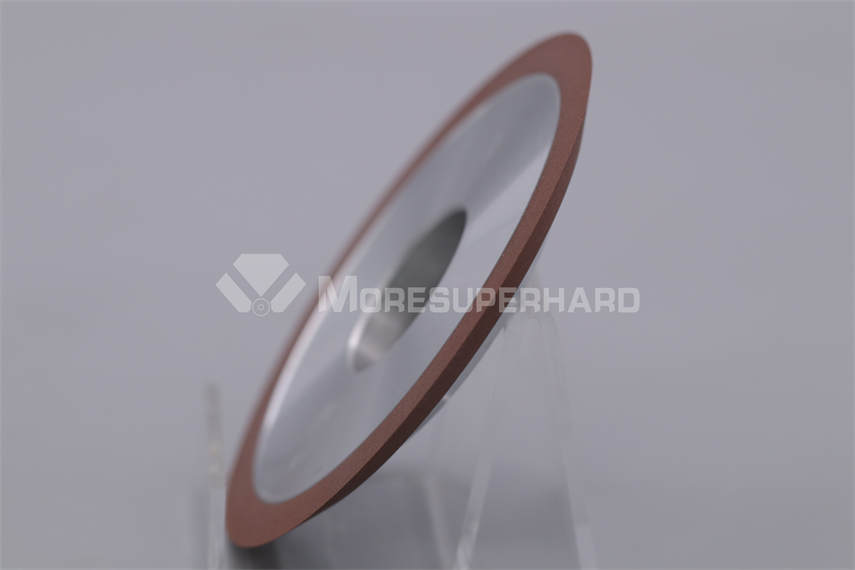

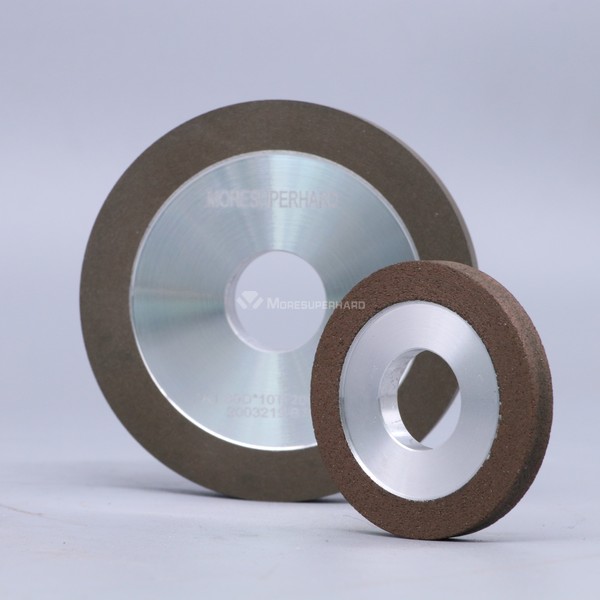

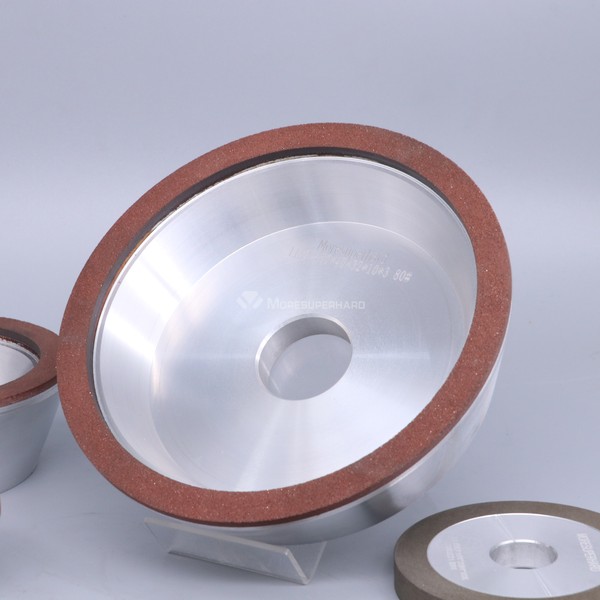

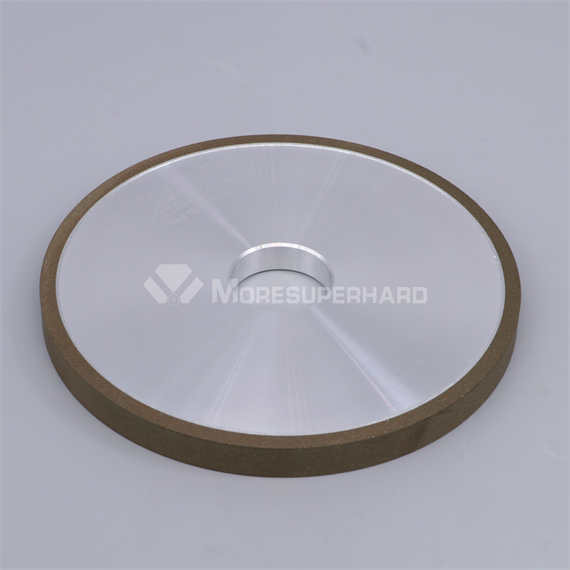

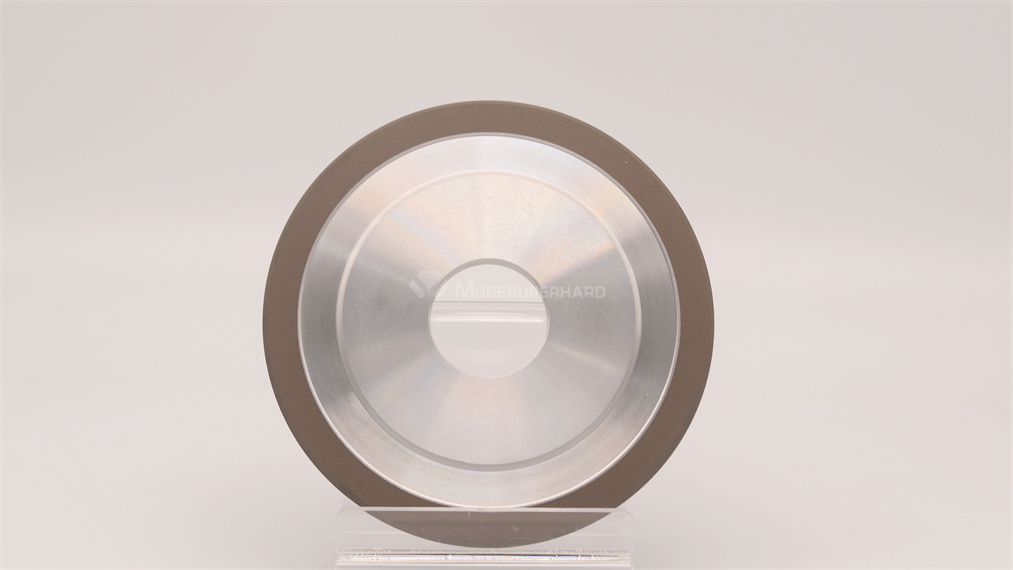

Resin bond diamond cylindrical grinding wheel

Resin bond diamond cylindrical grinding wheels for the oil and gas industry, providing precise solutions for resin bond diamond cylindrical grinding wheel for PCD/carbide, wear parts and gage blocks for oil & gas drill manufacturing.

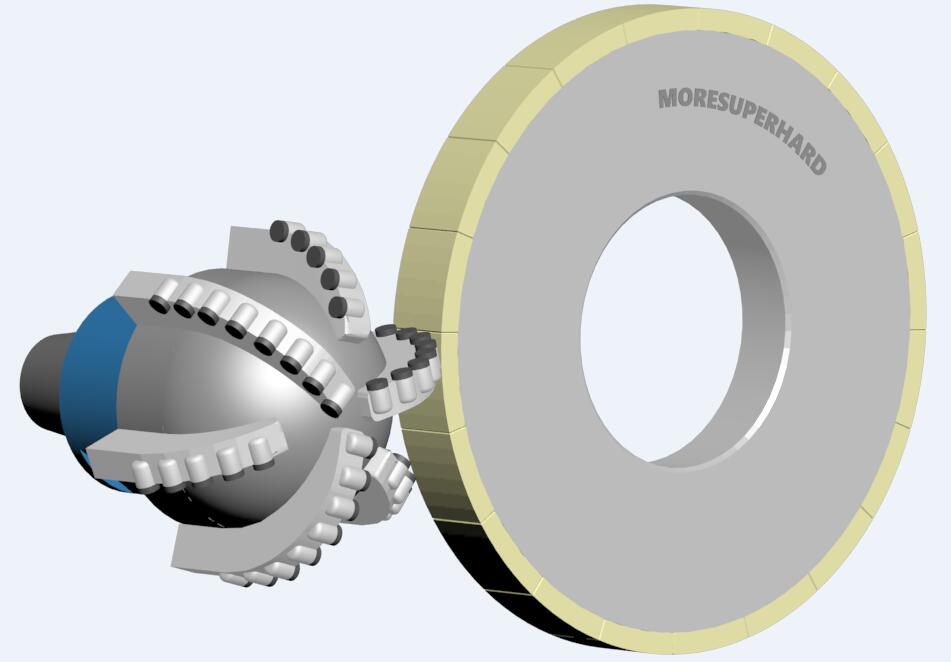

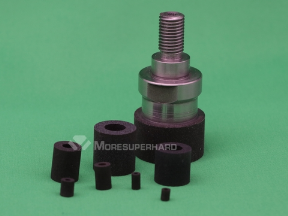

PDC (Polycrystalline Diamond Composite) drill bits grinding

Resin bond diamond cylindrical grinding wheel applicable industries: manufacturers of PDC drill bits (for example: geological drill bits, oil field mining drill bits, etc.)

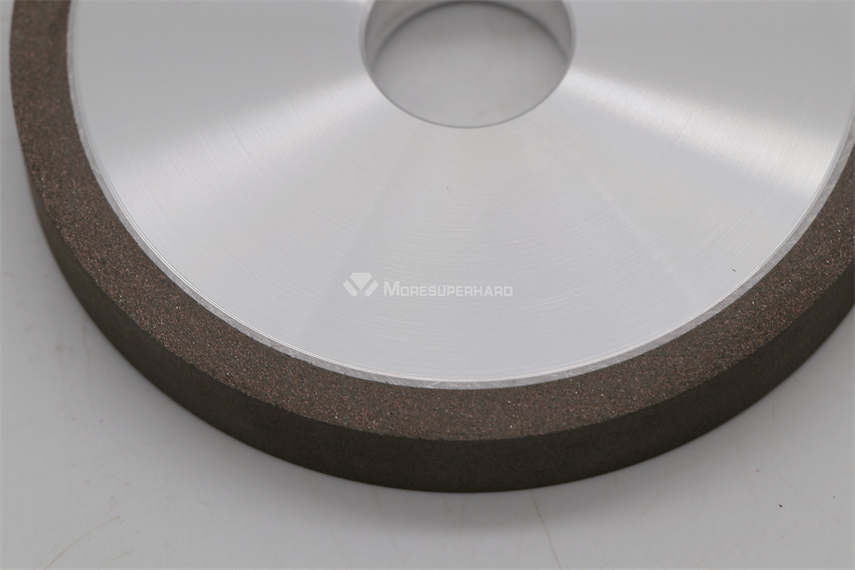

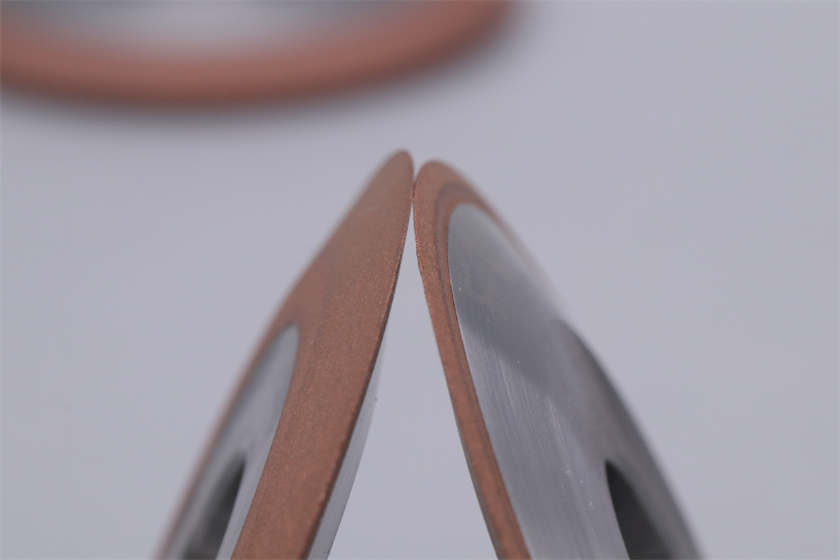

Features of Resin bond diamond cylindrical grinding wheel

Because the resin bond is soft, it is easy to deform during grinding; the metal bond has poor self-sharpening properties due to its strong ability to bond abrasive grains, and the grinding efficiency is low, and the metal bond grinding wheel will cause serious damage to the workpiece ; In terms of comprehensive grinding efficiency, abrasive durability and processing quality of workpiece surface, ceramic diamond grinding wheel is the choice for processing PDC.

Vitrified bond diamond grinding wheel combines the common characteristics of diamond and vitrified bond. It has strong grinding power, lower temperature during grinding, and less abrasive wear; it can adapt to the action of various coolants; the shape of the abrasive during grinding Good retention, high precision of grinding workpiece; There are more air holes in the grinding tool, which is beneficial to chip removal and heat dissipation during grinding, and it is not easy to block or burn the workpiece; the self-sharpening of the grinding tool is relatively good, and the time between dressing Long. Grinding advantages: 1. High grinding efficiency; 2. Very high wear resistance; 3. Small grinding force and low grinding temperature; 4. High precision, good surface quality and good surface quality of the workpiece. Good shape retention.