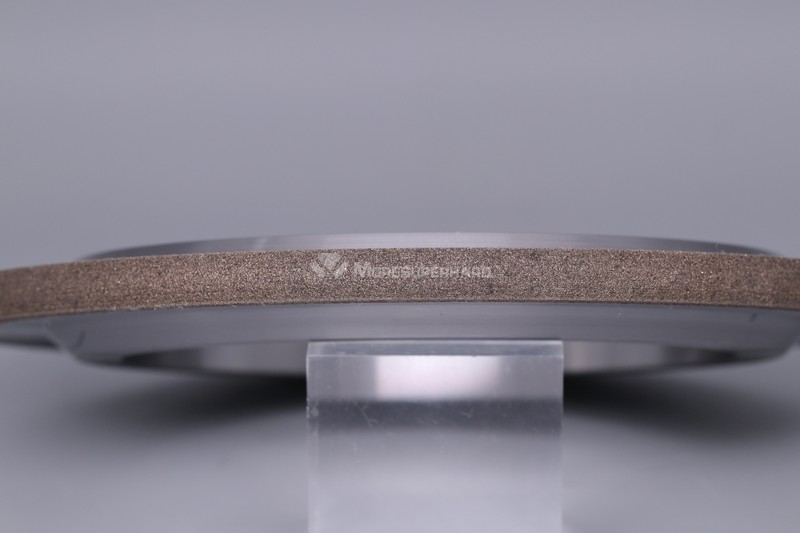

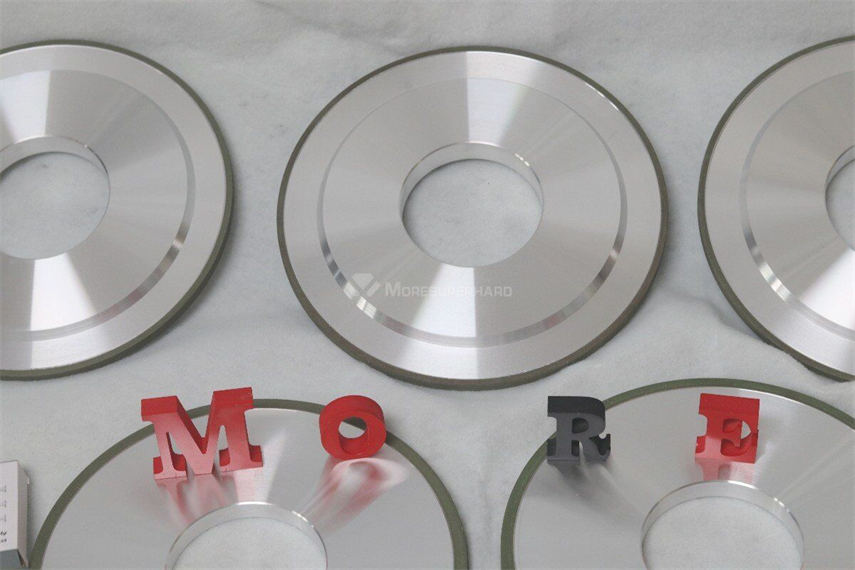

Resin Bond CBN Wheel for Grinding Hardened Steel

Resin CBN grinding wheel for grinding hardened steel is a good choice. Because of the high hardness of hardened steel, it is very hard to be grinded. Also, the hardened steel contains the iron element, we can not use diamond grinding wheel to process it.

Great work for hardened steel grinding – Resin bond CBN grinding wheel

CBN is the second hard thing in the world, only after diamond, it possesses high temperature resistance, and it is very stable that does not reaction with iron or another element.

Recently, we have successful customer case of resin bond diamond grinding wheel for hardened steel. This customer used to use the corundum grinding wheel, but he suffers from its low grinding efficiency and short working life. Then he seeks for a grinding wheel with good grinding ability and longer working life, that he can finish the work in short time, and save time from not changing wheels frequently. He does not have a high demand for surface roughness, but only need a sharp wheel.

He found us from our website and told what he wants. Based on his working condition, we recommend him a resin bond CBN grinding wheel with rough grit size. An important reason is that he can re-sharp this grinding wheel very easily, with one simple corundum stick or wheel is enough.

Finally, he is excited with our resin bond CBN grinding wheel, we help him to get a sharp and long work-life tool. He orders regularly and still explores another possibility of getting business with us in more applications.

What is a resin CBN grinding wheel?

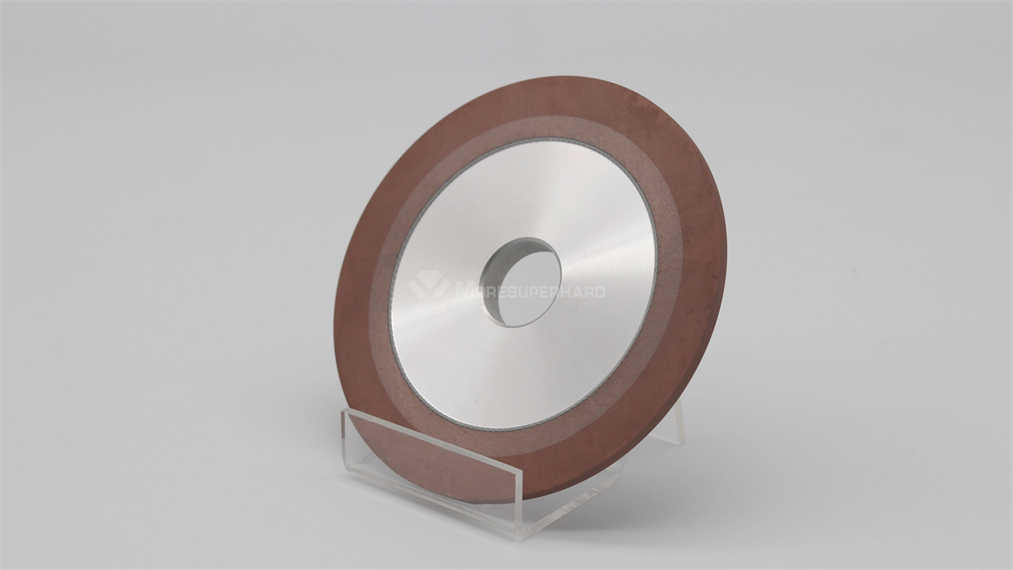

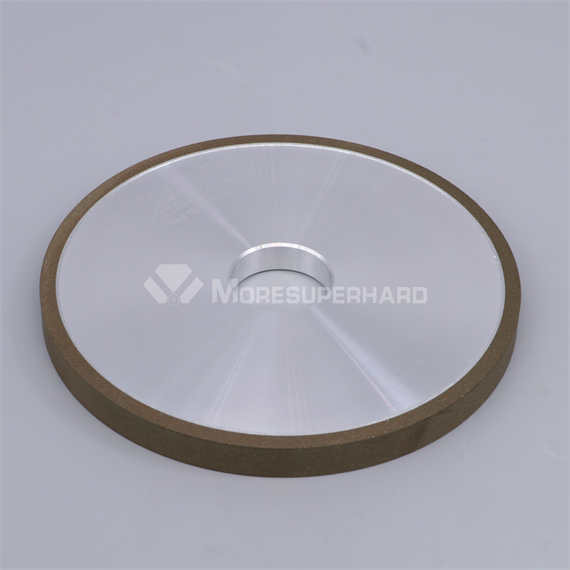

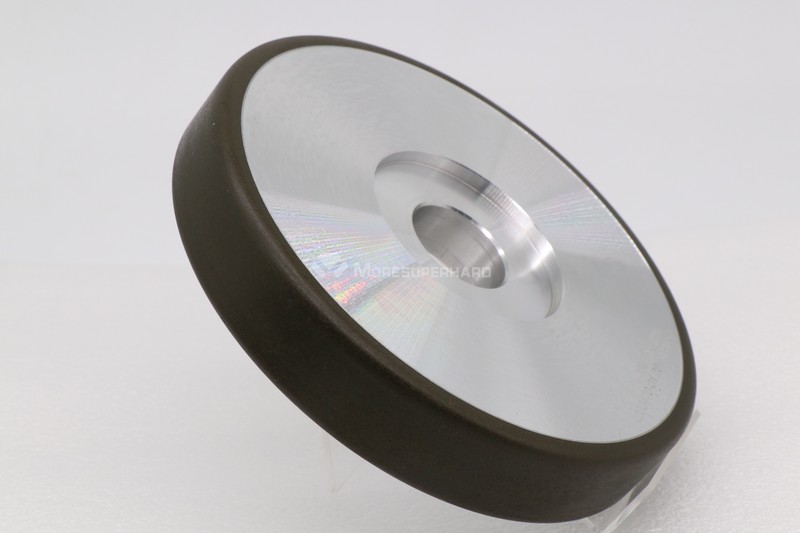

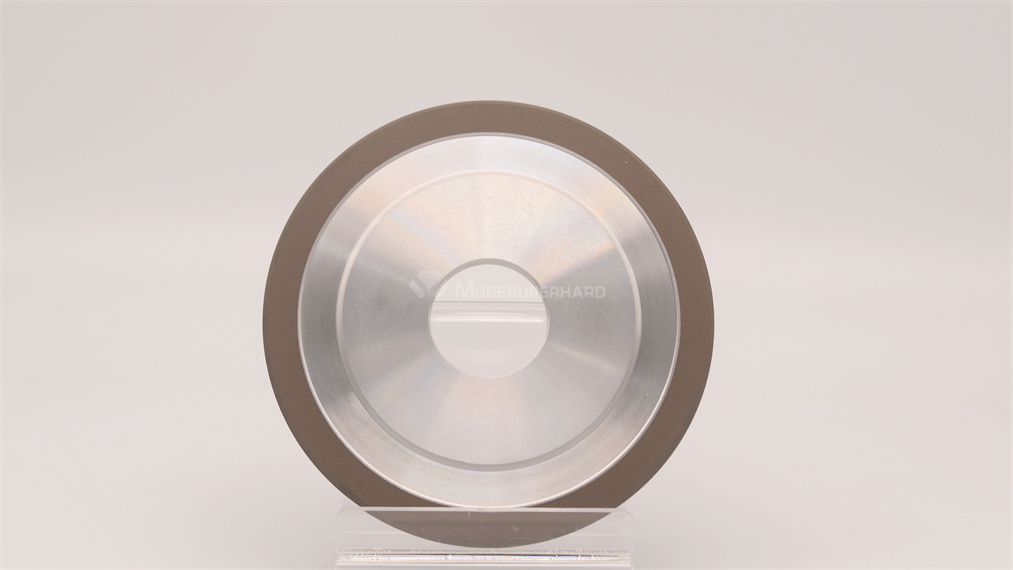

A resin CBN wheel is a grinding tool with a certain degree of rigidity (strength and hardness) by cementing a CBN grain together with an organic polymer compound as a binding agent. Resin CBN grinding wheels can process various metal and non-metal materials, especially in the field of fine grinding and polishing processing with superior processing characteristics.

Resin bonded CBN grinding wheels are widely used in rough processing, fine and polish grinding processes, and the resin bonded CBN grinding wheels have the following characteristics.

(1) High bonding strength. Compared with ceramic bond, resin bonded CBN grinding wheels have high bond strength, and the grinding line speed of resin grinding wheels reaches 80~120m/s, and can withstand large grinding pressure.

(2) It has a certain degree of elasticity. Compared with ceramic bonded CBN grinding wheels, resin bonded grinding wheels have good toughness, a certain degree of plasticity and ductility, and are suitable for preparing various specifications of flake grinding wheels and high-speed cutting grinding wheels. Due to a certain elastic deformation, it can buffer the effect of grinding force and thus has good grinding effect, polishing effect and can improve the roughness of the processed surface.

(3) It can be made into abrasives with various complex shapes and special requirements. Due to the low hardening temperature of resin bonded CBN grinding wheels, they can be hardened at room temperature and have a small shrinkage rate, so they can be made into grinding wheels of various complex shapes and special requirements.

(4) It helps to prevent burns on the workpiece being ground. The heat generated by the workpiece in the grinding process causes the resin to carbonize, prompting the blunted abrasive to fall off automatically, revealing new sharp abrasive grains, reducing the heat in the grinding area and avoiding workpiece burns.

(5) Low hardening temperature. Resin CBN grinding wheels have low hardening temperature, short production cycle, simple equipment, and are conducive to specialized production.