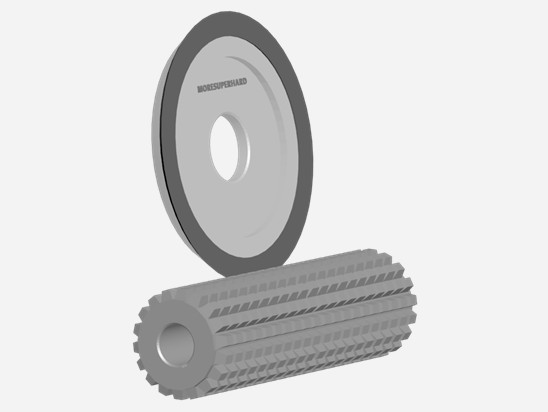

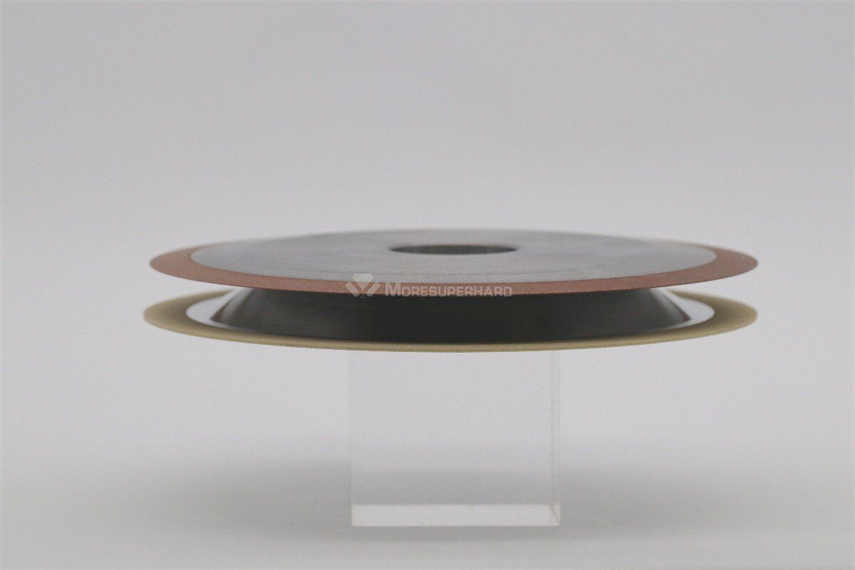

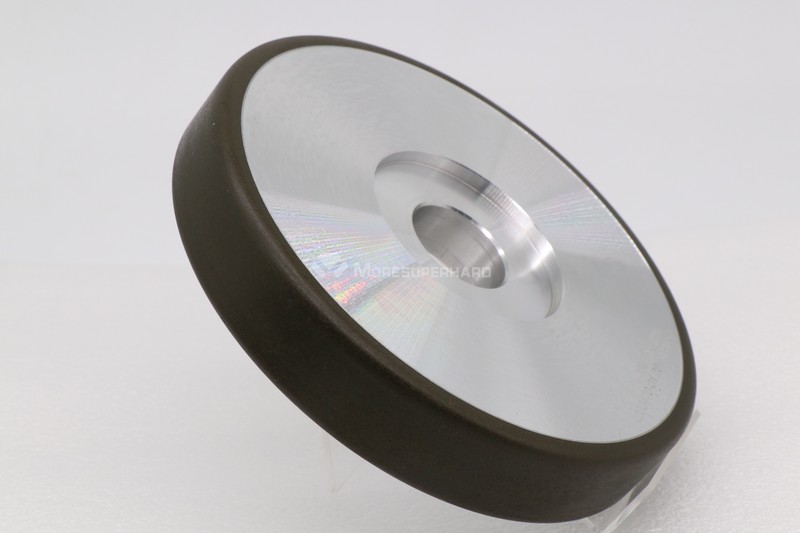

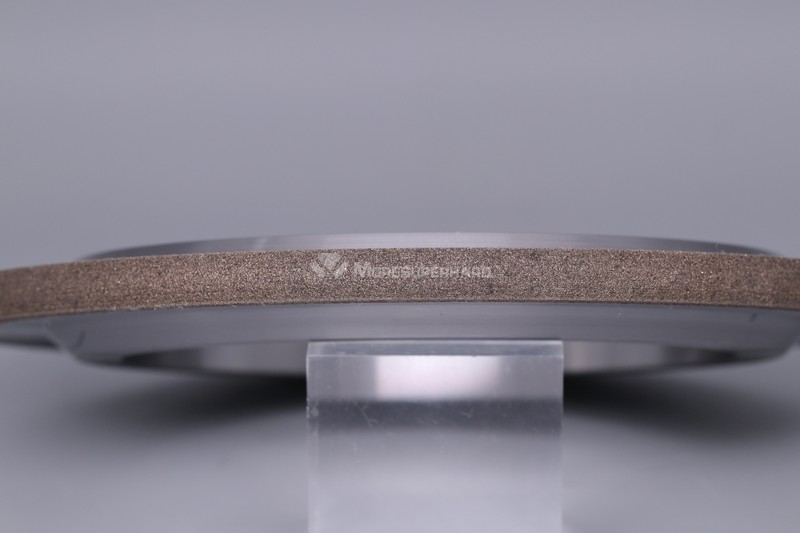

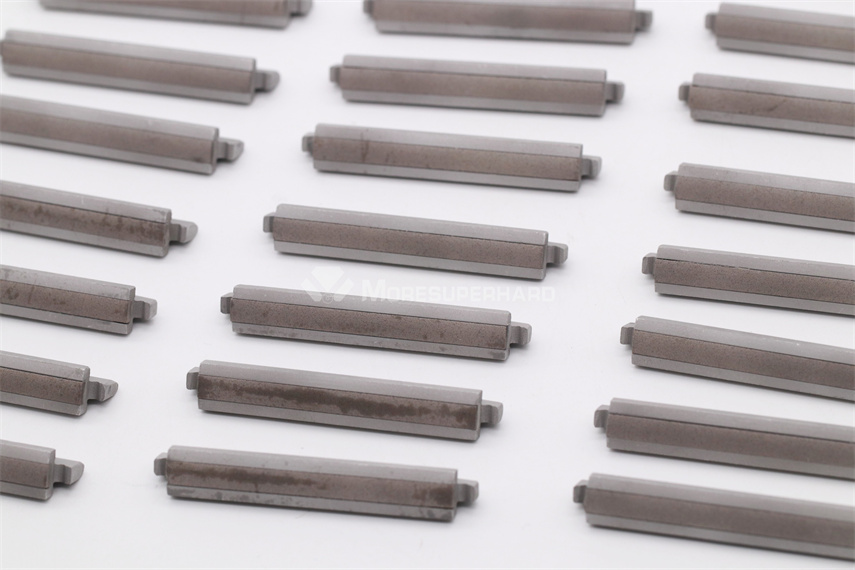

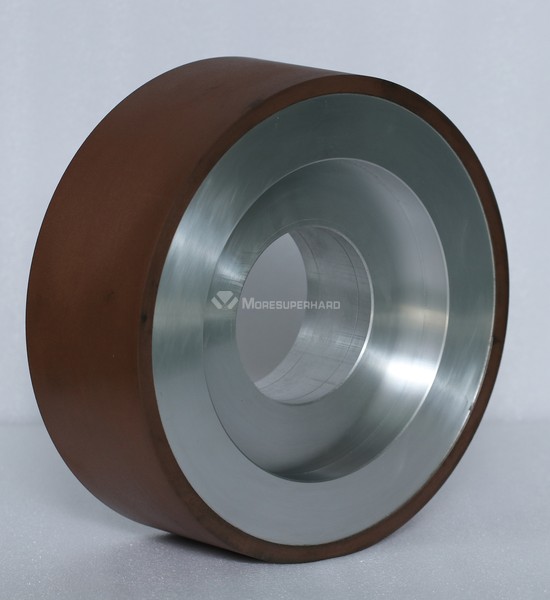

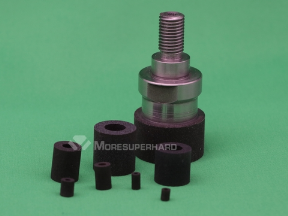

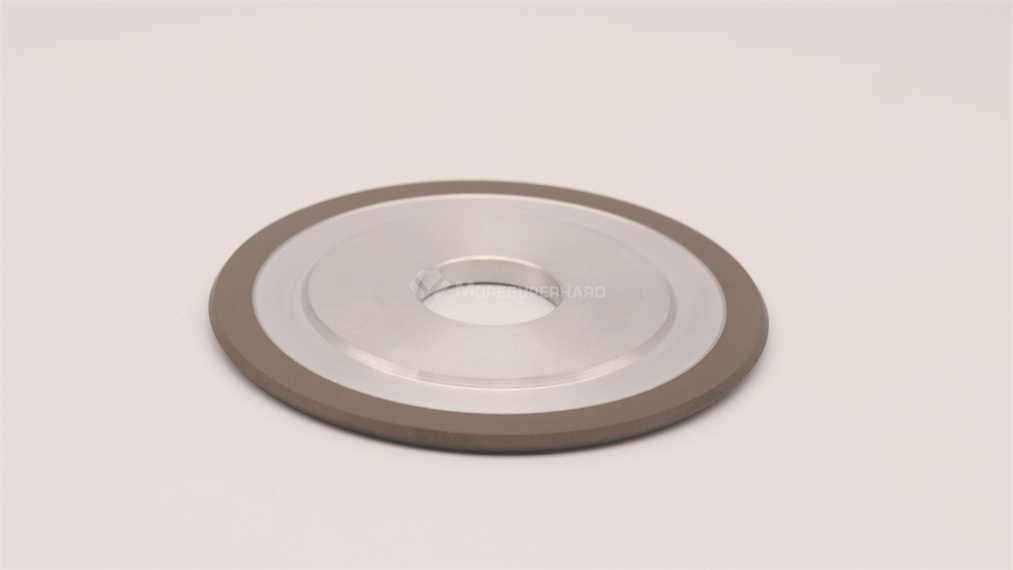

Resin diamond wheels for cylindrical grinding PDC drill bits

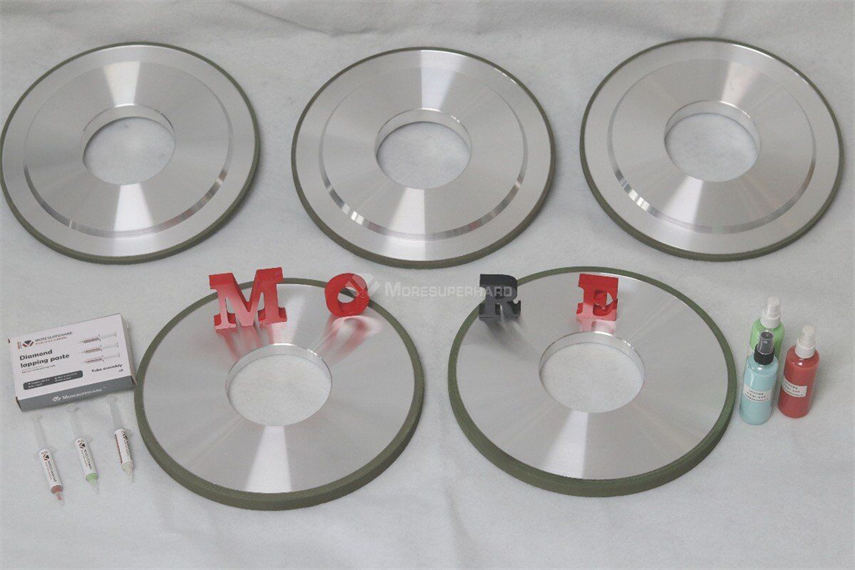

Resin Diamond Wheel for PDC Cutter / Drill Bits Grinding.

Resin bond diamond wheel is widely used in semi-precision grinding, fine grinding and polishing of cemented carbide, pdc composite sheet, PDC drill bits, ceramics, magnetic materials, crystals and other materials.

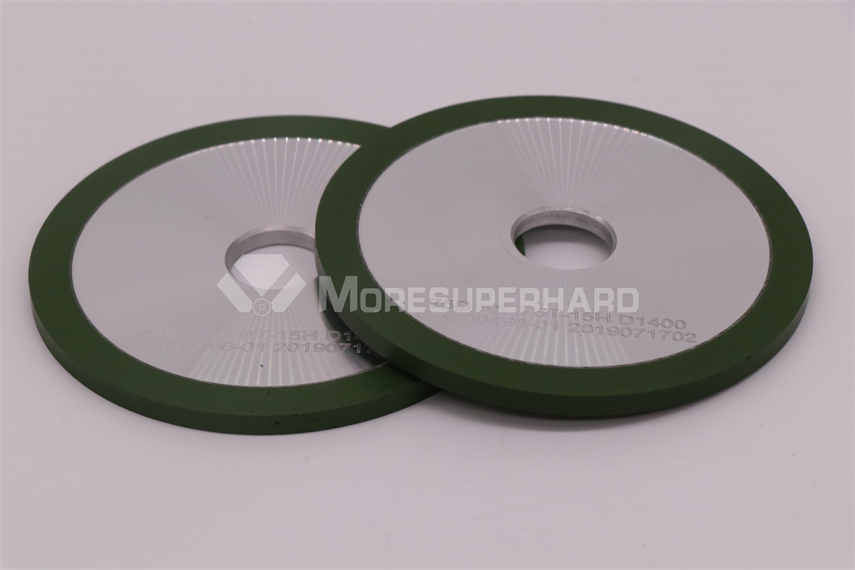

Resin bond diamond wheel is widely used in semi-precision grinding, fine grinding and polishing of cemented carbide, pdc composite sheet, PDC drill bits, ceramics, magnetic materials, crystals and other materials. Resin CBN grinding wheel: mainly used for grinding cast iron, high-speed steel containing tungsten and molybdenum, vanadium alloy steel, cobalt alloy steel, and quenched steel. Performance characteristics: The resin bond diamond grinding wheel has good self-sharpening, full of elasticity and good polishing and grinding performance; it is not easy to block and heat, high grinding efficiency, good quality, and easy to dress.

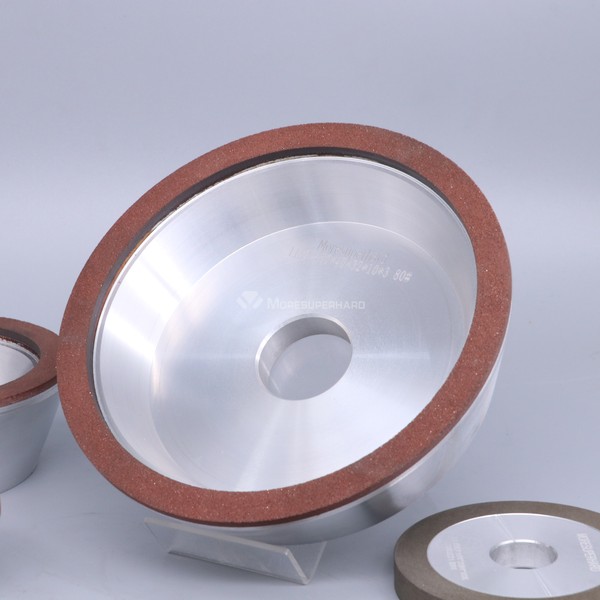

Pay attention to the time when choosing a resin bond diamond wheel:

(1) The hardness of the grinding wheel should not be too soft, otherwise, it is not easy to maintain the corners of the grinding wheel. When grinding the side surface of the spline, choose the hardness. • When grinding the bottom diameter of the spline, the contact area is large and the workpiece is easy to work. The hardness of the grinding wheel is better.

(2) When grinding hardened steel, choose 4~70# grain size; when grinding quenched and tempered californium, it is easy to stick iron chips, choose 46», ZR:, looser grinding wheel.

(3) When the diameter of the grinding wheel is 150~200 mm, the hardness can be softer, and when the diameter is 100 mm, the hardness of 2 Gen should be selected.

(4) When the longitudinal cutting speed is low and the cutting depth is large, a softer grinding wheel can be selected.