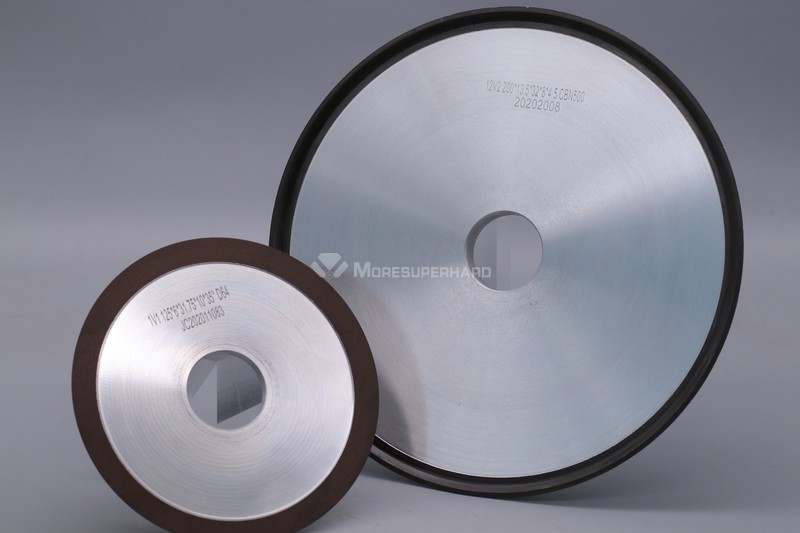

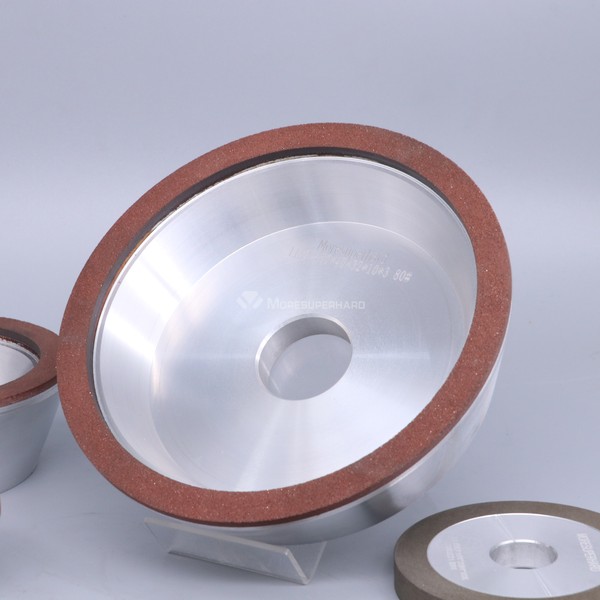

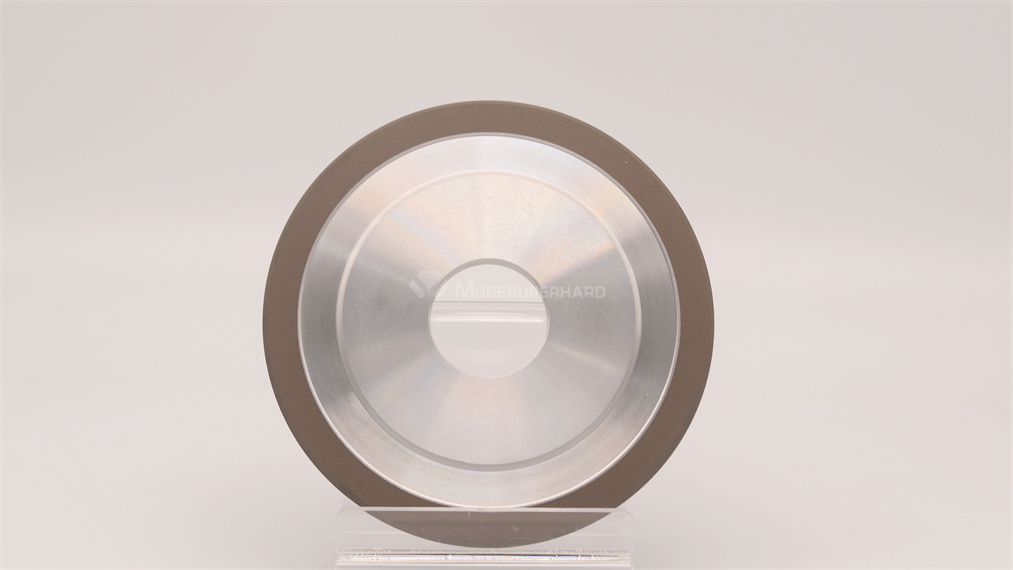

Resibond diamond wheel for face of quartz

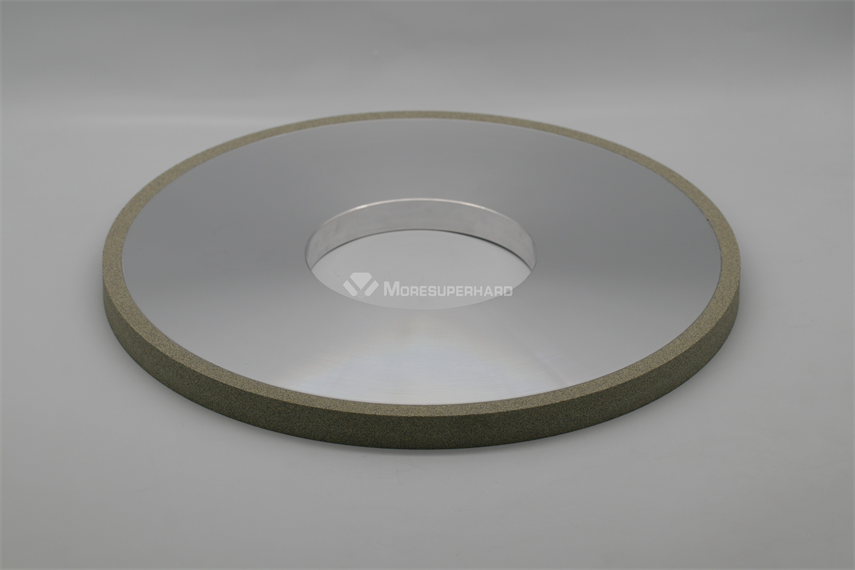

Resin diamond grinding wheels are widely used in semi-precision grinding, fine grinding and polishing of cemented carbide tools, PDC cutter, PDC drill bits, ceramics, magnetic materials, crystals and face of quartz, etc

Performance characteristics of resin bond diamond grinding wheels

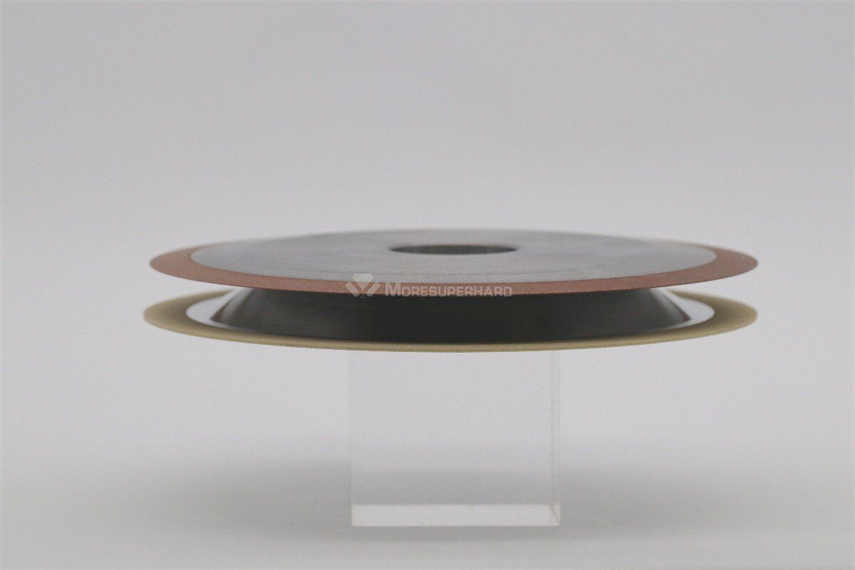

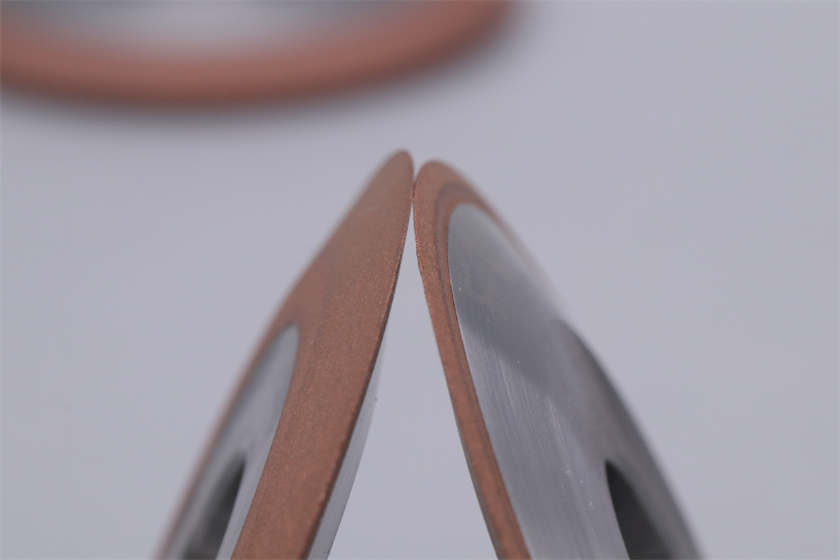

* The resin bond diamond grinding wheel has good self-sharpening, elasticity and good polishing and grinding performance

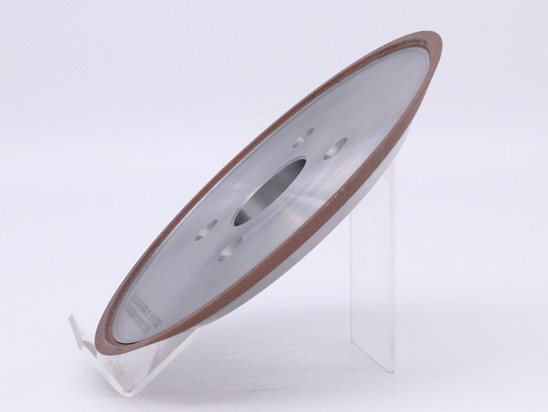

* It is not easy to block and generate heat, has high grinding efficiency, good quality, and is easy to repair

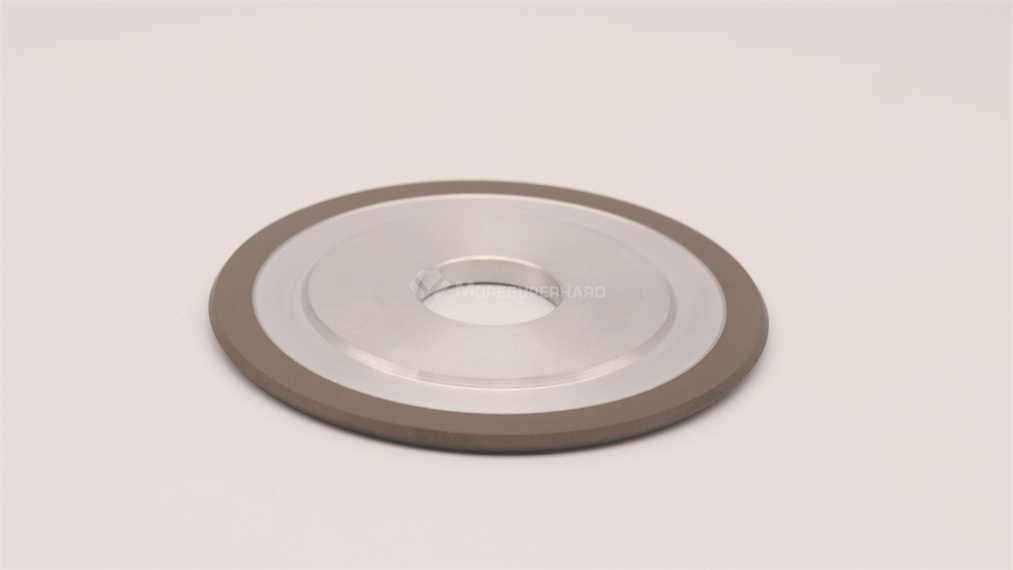

*Resin bond is usually made with heat-cured resin mainly composed of phenolic resin. Resin bond wheel has excellent grinding ability, surface finish and minimal chipping. It is widely applied for difficult-to-machine materials such as cemented carbide, ceramics, glass, and silicon as well as ferrous materials such as high-speed steels and sintered ferrous metals

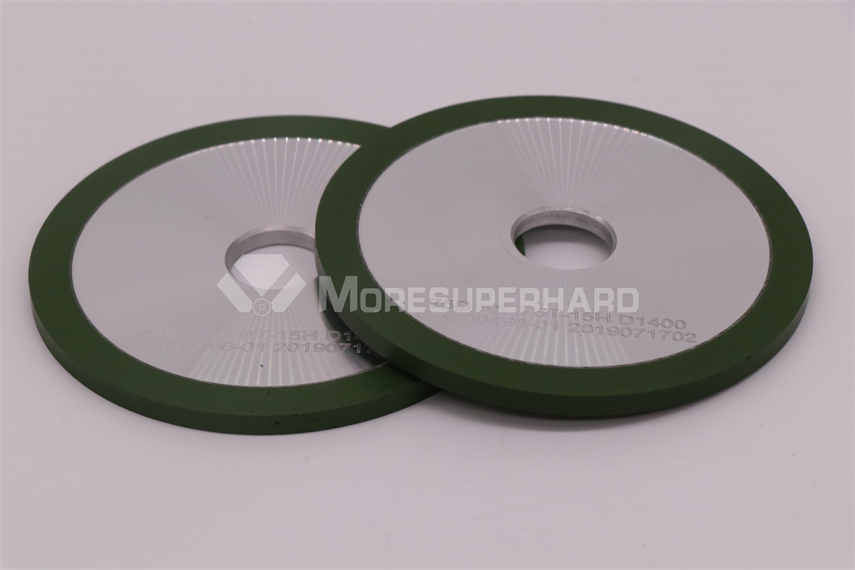

* Resin bond usually has some added filler such as organic and inorganic materials, metals, etc. into the phenolic resin in order to control its wear resistance, heat resistance, grit retention and lubrication.

* Resin wheels are low in Young′s modulus ; therefore they have excellent characteristics in: processing efficiency, free cutting, surface finish, and minimal chipping

* Resin bond wheels have shorter wheel life because the adhesion between the grit and the bond is not as strong as that of metal bond wheels. However, resin bond has much better cutting ability when processing hard-to-grind materials such as cermets, ceramics, etc