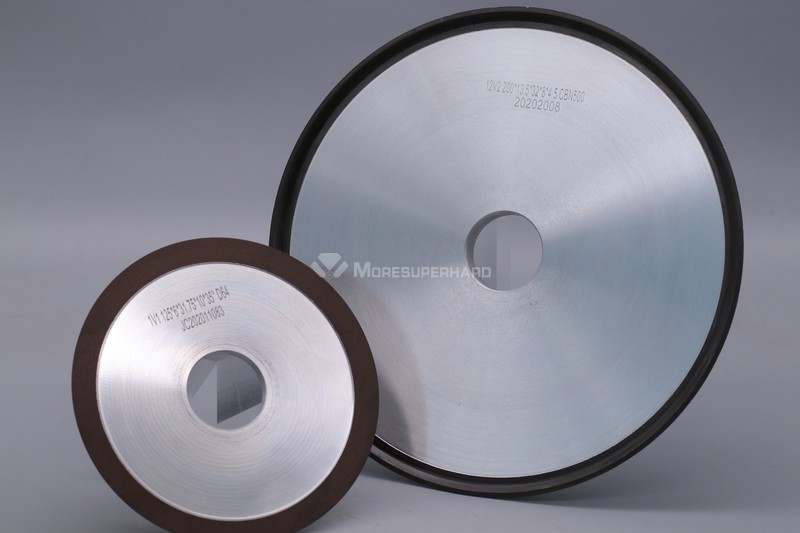

Dish Type Resin diamond grinding wheel online purchase

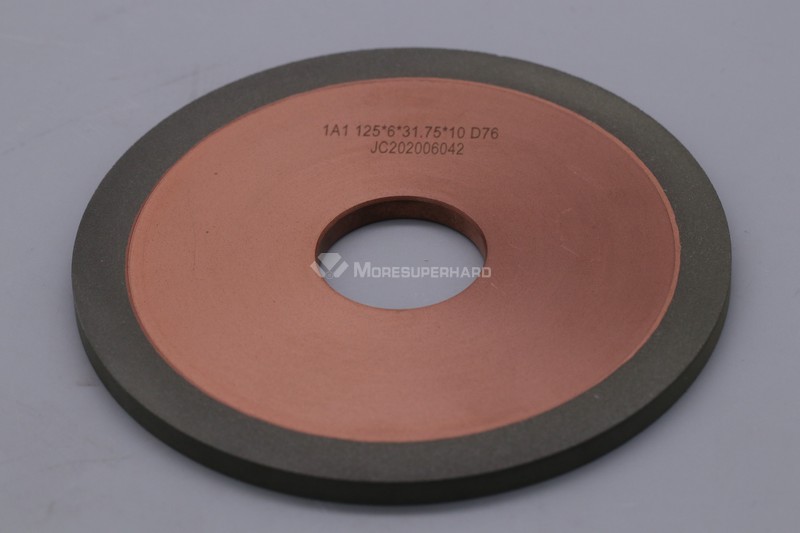

Resin Bond diamond wheels are mostly used for precision grinding of cemented carbide, cermets and ceramics.

Resin diamond grinding wheel have shorter wheel life because the adhesion between the grit and the bond is not as strong as that of metal bond wheels. However, resin diamond grinding wheel has much better cutting ability when processing hard-to-grind materials such as cermets, ceramics, etc.

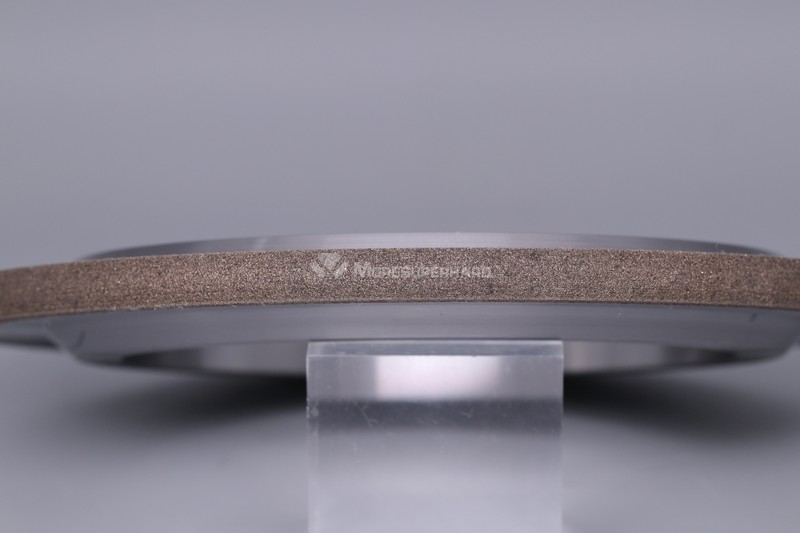

* The diamond and CBN abrasives used for resin bond wheels are different from those used for metal bond. Resin diamond grinding wheels are irregular-shaped and easy to microfracture. By doing so, they also create new cutting edges constantly while grinding. In order to improve grit retention, the diamond is metal-coated and the surface is more uneven shaped.

Resin diamond grinding wheels are typically used for wet grinding, but they can be used for dry grinding by adding some filler to reduce heat generated by grinding and improving their cutting ability.

Applications of resin diamond grinding wheel

* Resin Bond diamond wheels are mostly used for precision grinding of cemented carbide, cermets and ceramics.

* Because of the bond elasticity, they are used for finish grinding of silicon, glass, ceramic-made electrical parts, etc. which require excellent surface finish.

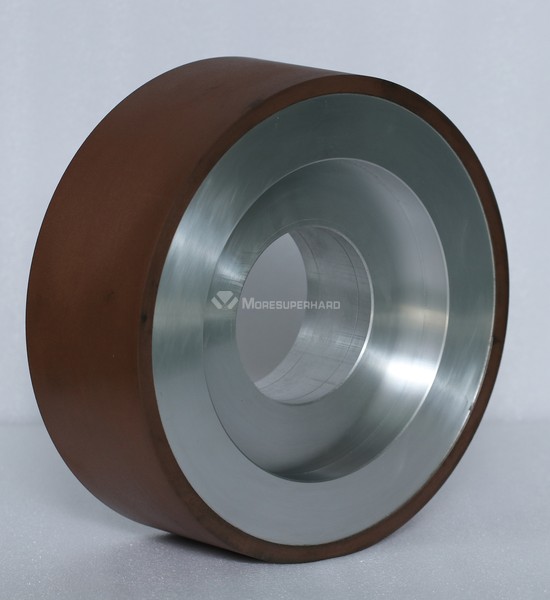

Application of resin cbn grinding wheel

* Resin bond wheels are suitable for grinding ferrous metals such as cast iron, high speed steels, and sintered iron.

* Resin cbn grinding wheels are suitable for processing hard to machine materials because CBN grains are much stronger than conventional abrasives.

* Resin cbn grinding wheels can perform precision grinding because they wear much less than conventional abrasives.