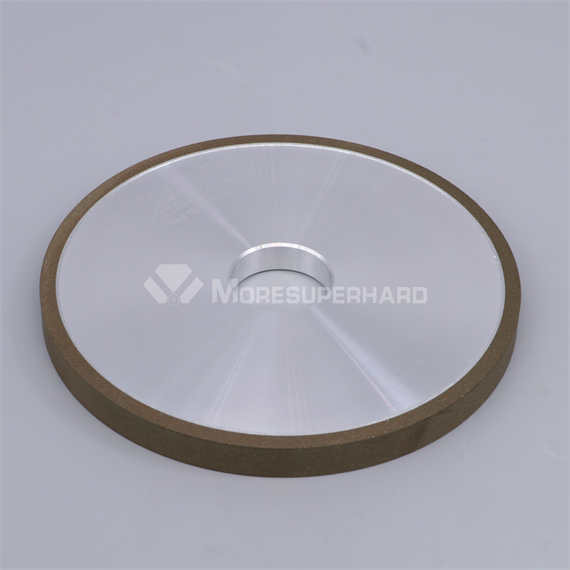

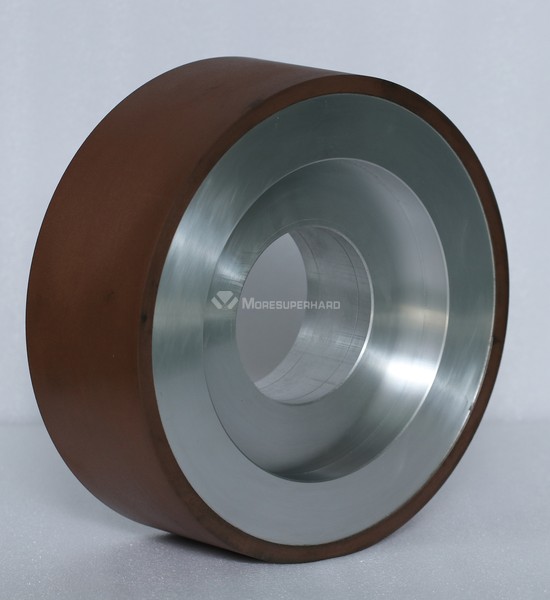

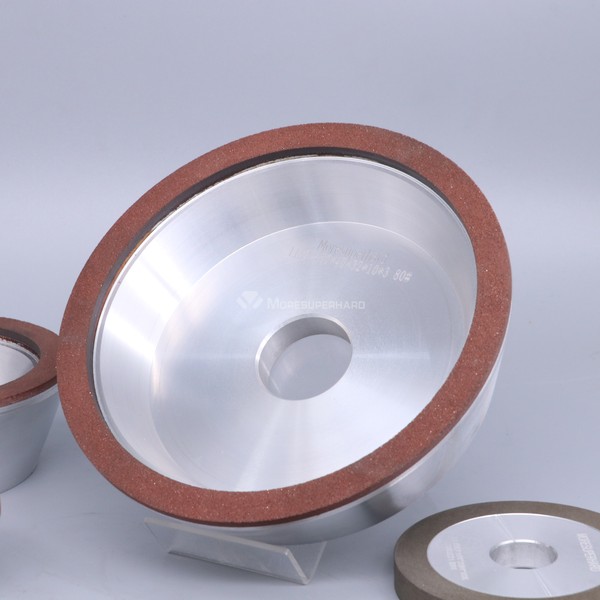

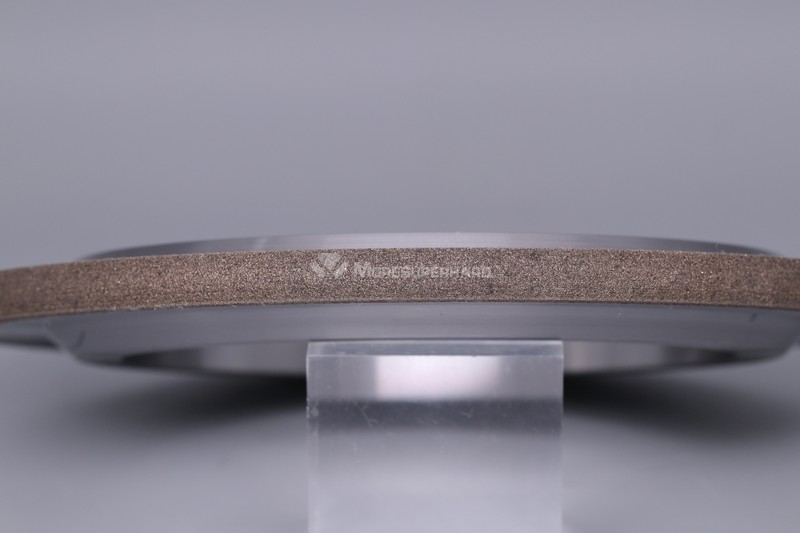

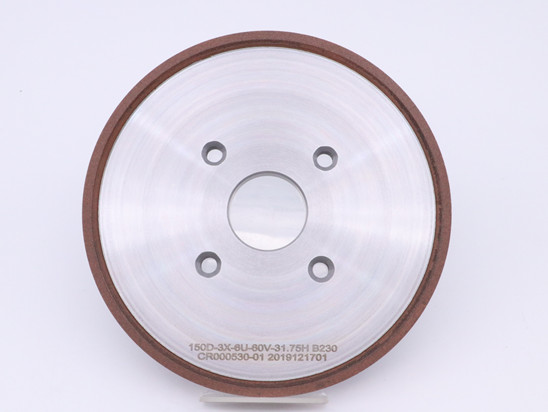

Special-shaped resin diamond wheel for grinding steel workpieces

►Excellent Grinding Action

►less apt to experience loading, and they dress easily for added convenience

►Convenience and Ease of Use

►Grinding abilities apply to both wet and dry tasks on processing objects such as harden steel, glass, ceramic, carbide alloys, ferrite, refractories, semi conductors, and other electrical carbon products.

Resin-bonded synthetic diamond grinding wheels are mainly used for the flat and cylindrical grinding of hard alloy measuring tools, tungsten steel, high-speed steel, alloy steel, glass, gemstones, magnetic materials, ceramics, molds, etc. They can also be used for cutting in grinding and form grinding. Due to the characteristics of diamond abrasives (high hardness, high compressive strength, and good performance), diamond grinding wheels are an ideal tool for grinding hard and brittle materials and hard alloys in grinding processing. Not only High precision, good rtoughness, low grinding tool consumption, and long service life, and can also improve labor conditions. Therefore, it is used for low iron content metal and non-metallic hard brittle materials that are difficult to process with ordinary abrasive tools, such as hard alloy, high aluminum porcelain, optical glass, agate gem, semiconductor materials, stone, etc. Edge grinding, grinding, polishing, etc. for the cylindrical grinding of hard alloy products