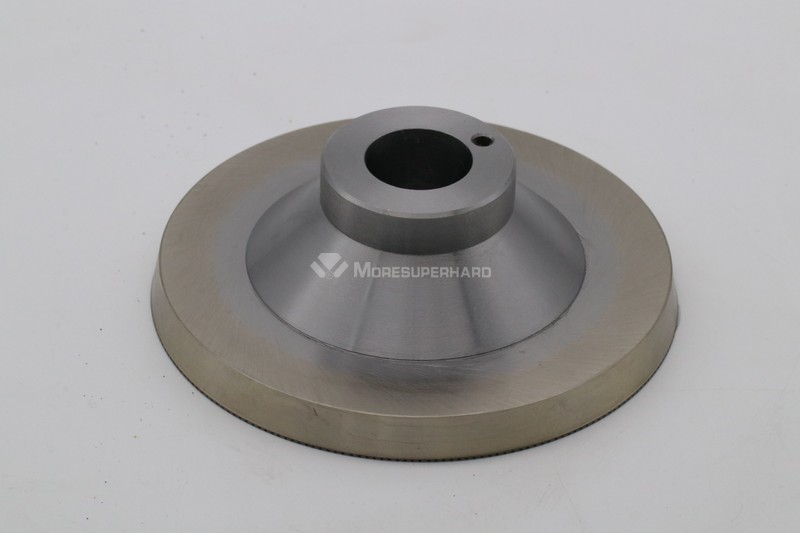

Home » Grinding Wheels » PCD polycrystalline wear resistant supplier

PCD polycrystalline wear resistant supplier

PCD wear surfaces are used for

• Vee Supports

• Backing Plates

• Gauging Fingers

• Gauging Points

Contact US

Get Price

Share:

Content

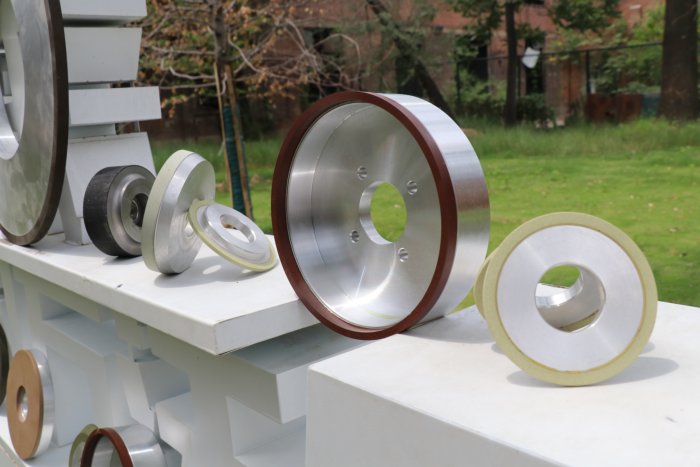

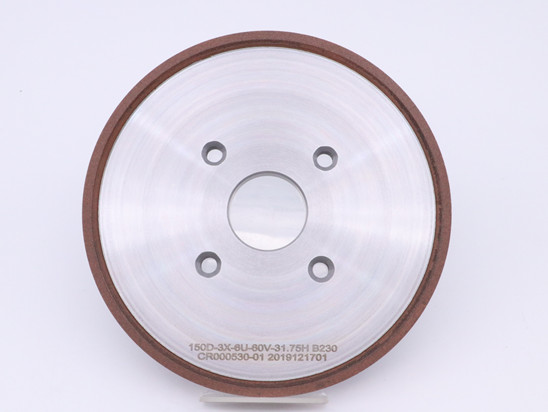

Application of PCD wear resistant parts

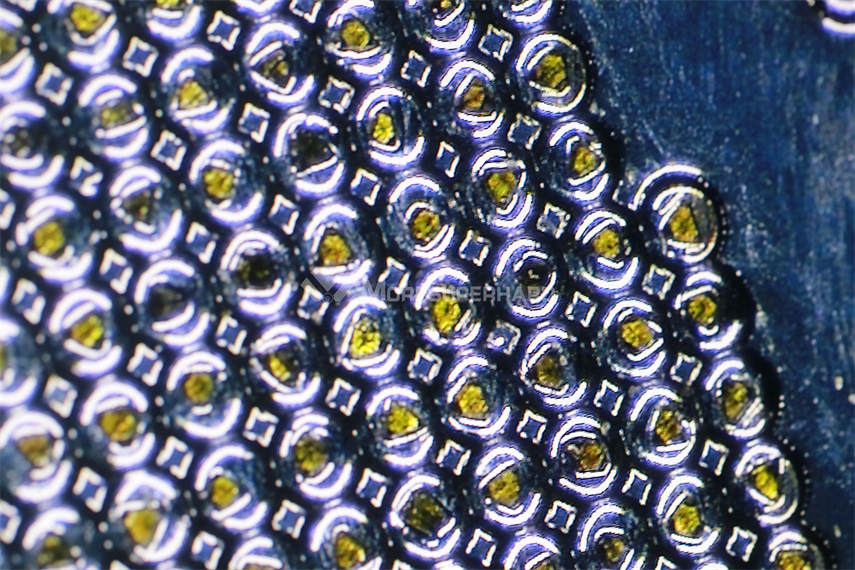

* PCD Bearing, Bearing. Such As Front Plate,Pressure Rotor,Loading Shoe,Backing Plate.

* Electronic Components. Such As Punch Tool,Rounded Shaped Die,Rectangular Shaped Die,Diamond Chip Heater, Bonding Of IC Chips.

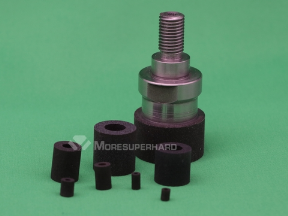

* Machine Tools. Such As Collet, Centerless Blad, Fixed Lathe Centres, Gauge Heads. and Support pads for lathes.

* Automible Industry (Camshaft, Crankshaft, spray nozzles) , Measuring fixtures,Measuring probes and points, Etc

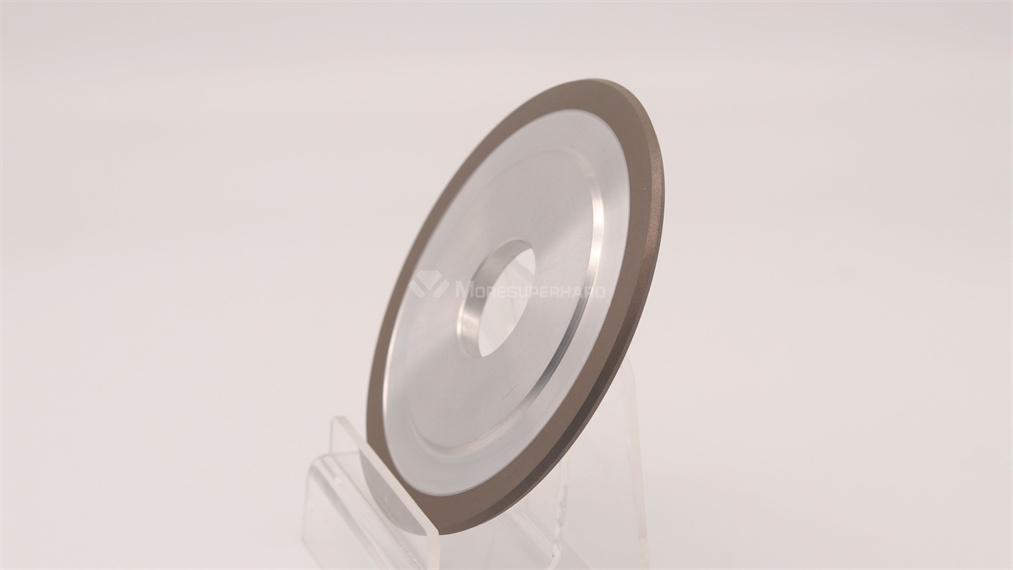

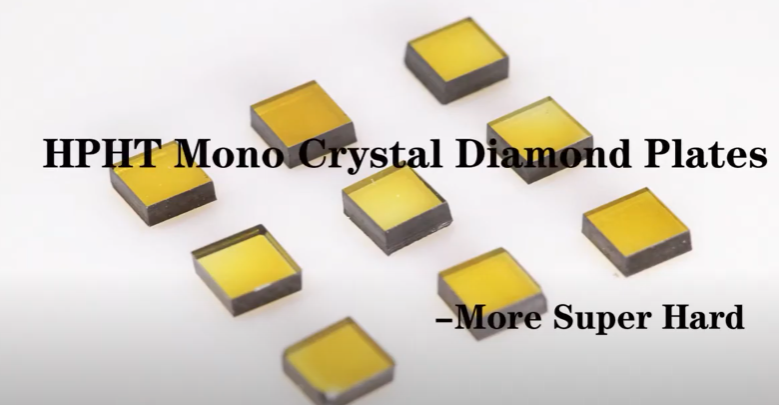

Advatages of wear-resistance components of synthetic diamond and PCBN:

- Surface roughness is equivalent to mirror (Ra<20nm).There is nodamage to surface of works.Can retain the original brightness.2.Compared with cemented carbide and ceramics, diamond has thelowest friction coefficients with ion and steel, this reduces the friction forceand improves the precision of machining of works.

- Long life and wear resistant.Longer Availability work time and lowerwastrel rate,reduce the overall cost.

Inquiry

More Grinding Wheels