High Precision PCD wear resistant parts supplier

PCD wear parts are used for workpiece support and reference, such as Dead Centre and Centre points,Support pads for lathe machines, Centring and positioning components,Measuring probes and points, Master gauges, others PCD wear parts

Application of PCD wear resistant parts

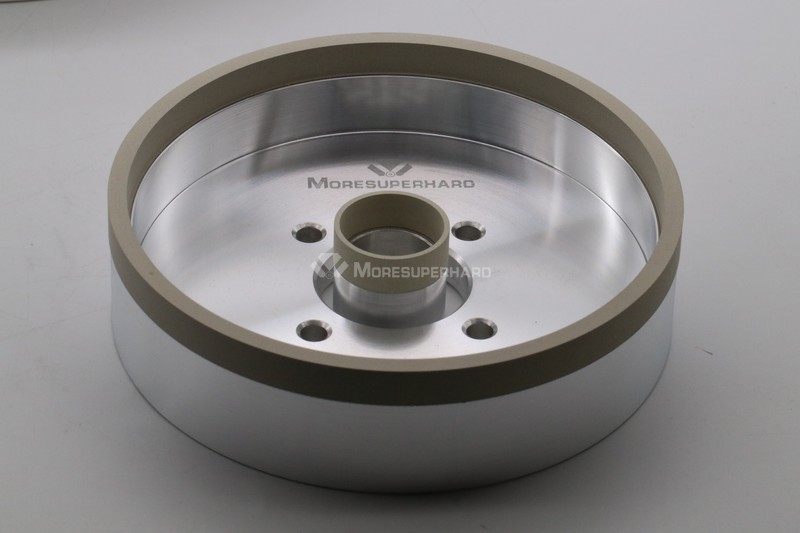

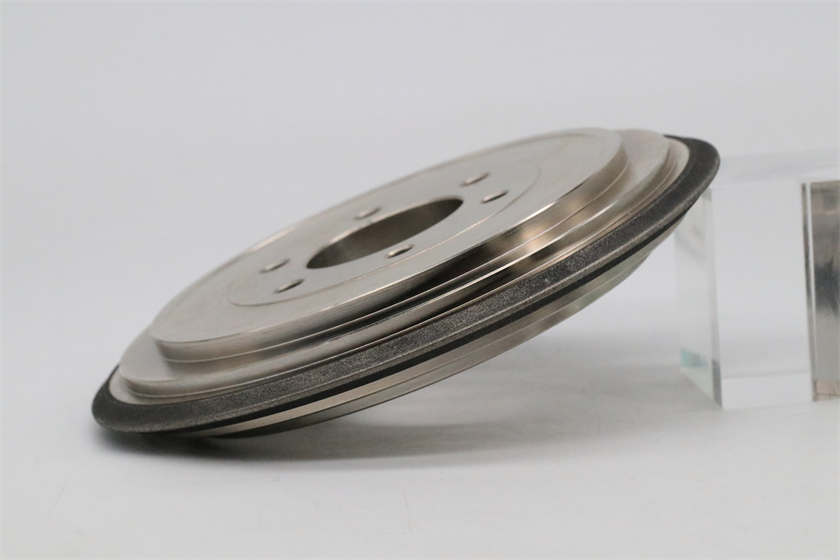

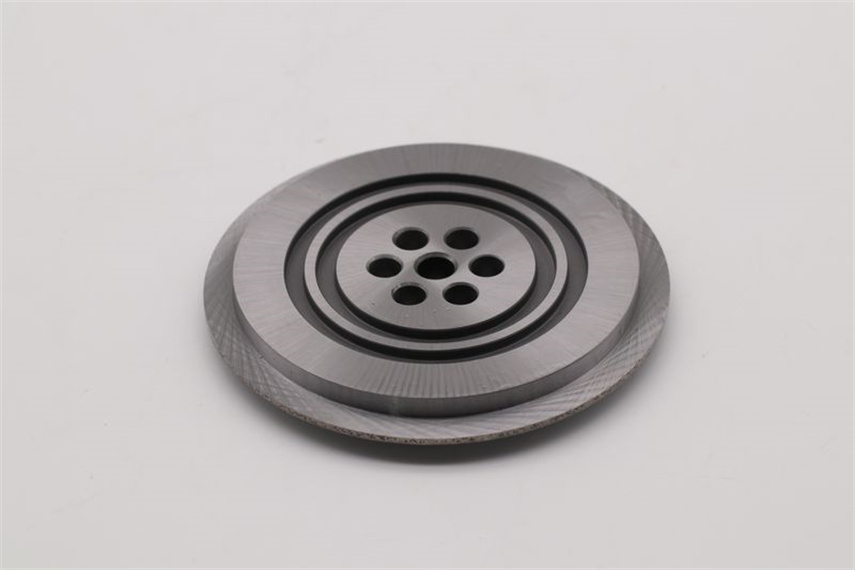

* PCD Bearing, Bearing. Such As Front Plate,Pressure Rotor,Loading Shoe,Backing Plate.

* Electronic Components. Such As Punch Tool,Rounded Shaped Die,Rectangular Shaped Die,Diamond Chip Heater, Bonding Of IC Chips.

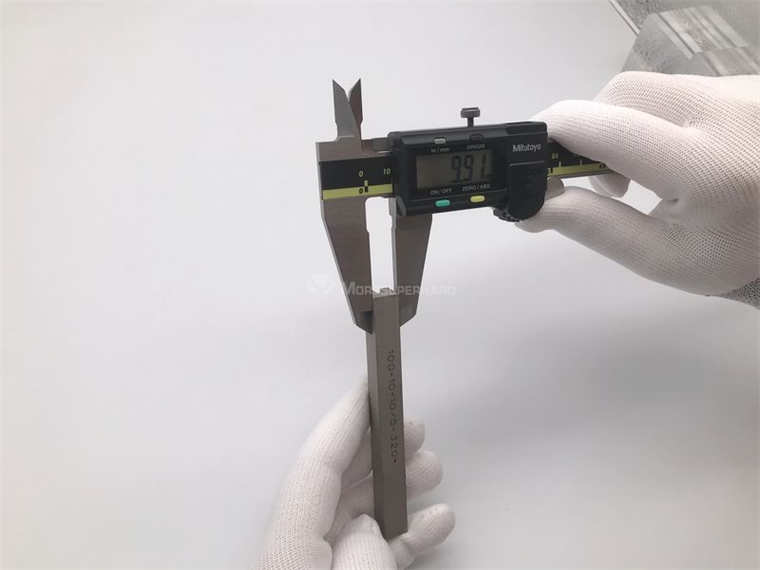

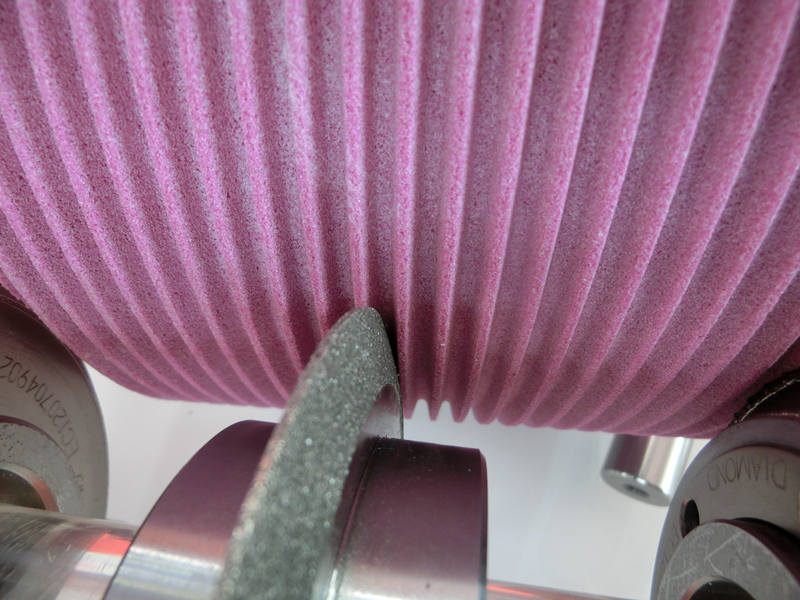

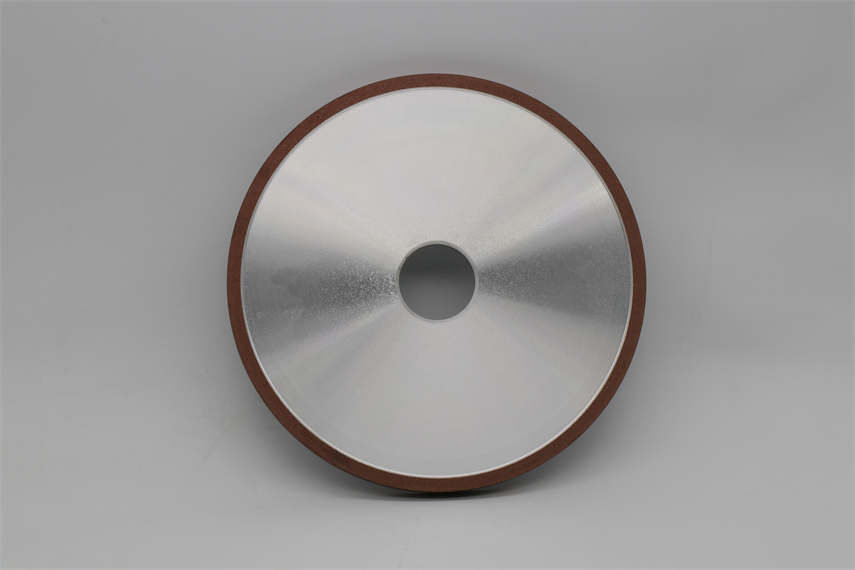

* Machine Tools. Such As Collet, Centerless Blad, Fixed Lathe Centres, Gauge Heads. and Support pads for lathes.

* Automible Industry (Camshaft, Crankshaft, spray nozzles) , Measuring fixtures,Measuring probes and points, Etc.

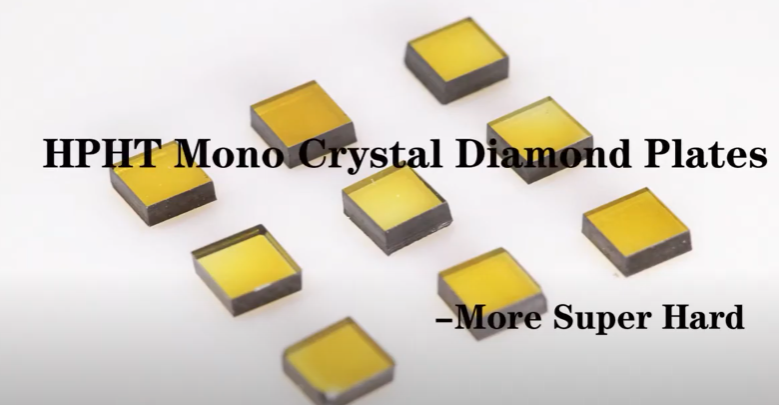

Advantages of PCD polycrystalline wear parts

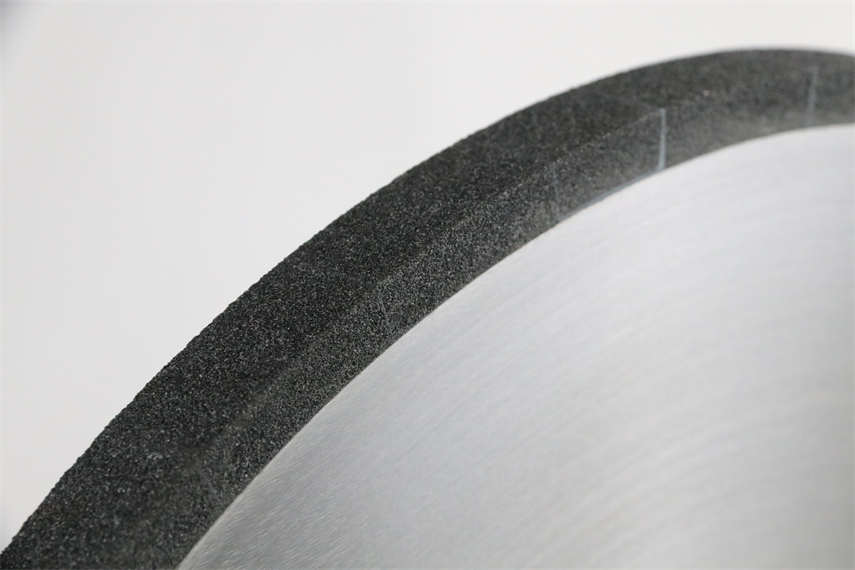

- High hardness, synthetic diamond is nearly 10 times the hardness of ordinary cemented carbide, and it is more resistant to wear;

- Good hardness and high temperature resistance, and can withstand the environment with slight chemical reagent solution, stable and non-reaction;

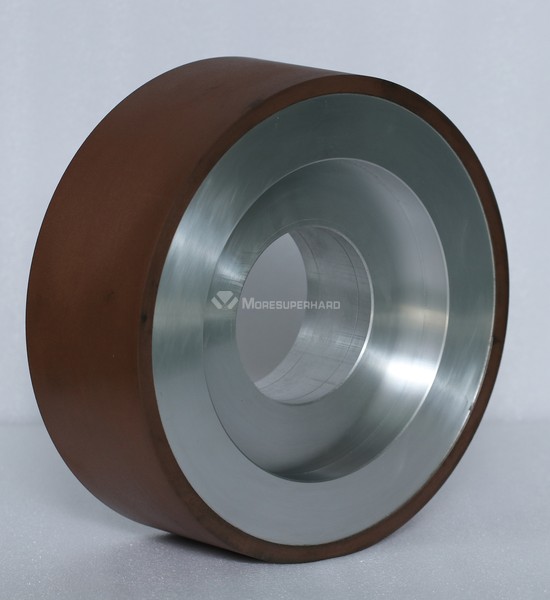

- Vacuum welding technology can be combined with metal material welding, which can perfectly replace conventional hard alloy wear parts;