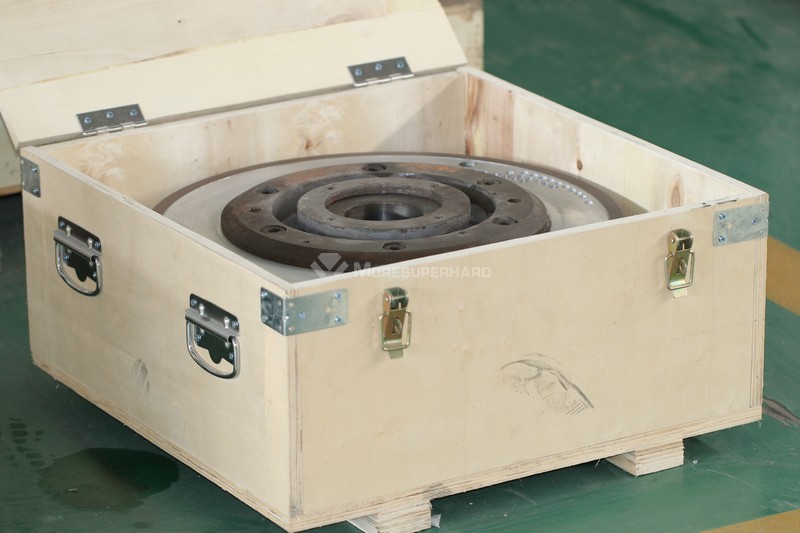

Resin bond diamond wheel factory

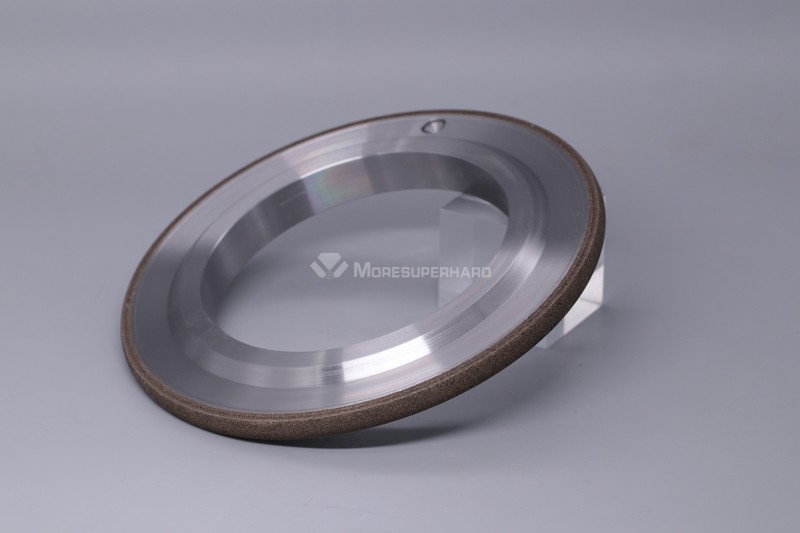

Resin bond diamond wheel is solidified at low temperature, the production cycle is short, and the equipment and supply process are relatively simple; because the resin has fluidity, it is easy to form a grinding wheel with a complex surface.

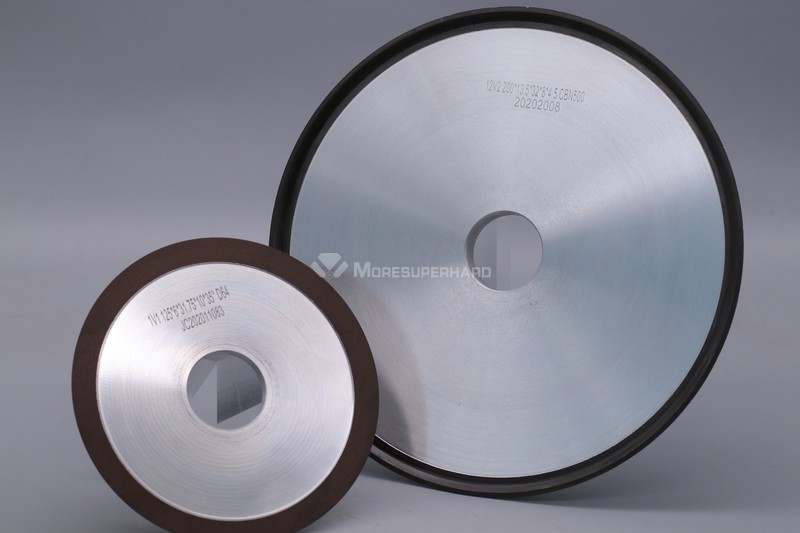

Diamond resin grinding wheel can be selected according to the product model (parallel grinding wheel, parallel arc grinding wheel, double-sided concave grinding wheel, double bevel grinding wheel, bowl grinding wheel), etc.

Applications of resin bond diamond wheel

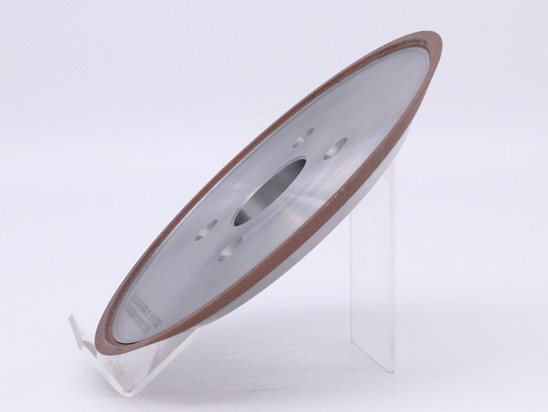

Parallel grinding wheel: mainly used for cylindrical grinding and blade machining of cemented carbide

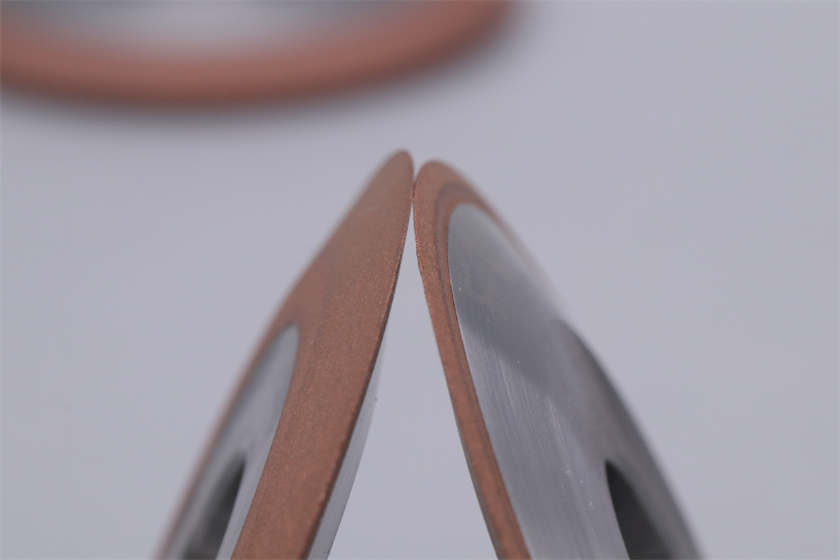

Parallel arc grinding wheel: mainly used for forming grinding of cemented carbide and forming grinding of arc surfaces

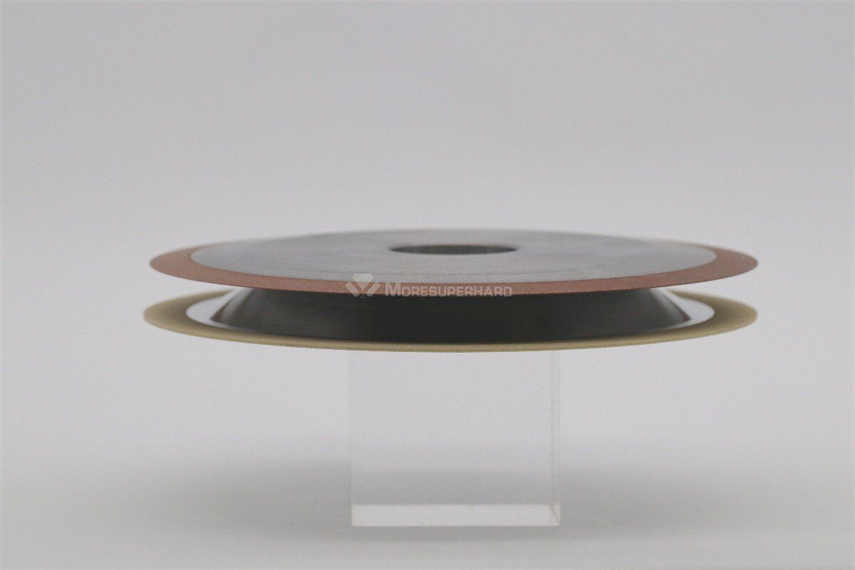

Double-sided concave grinding wheel: mainly used for grinding measuring tools and coreless grinding wheels

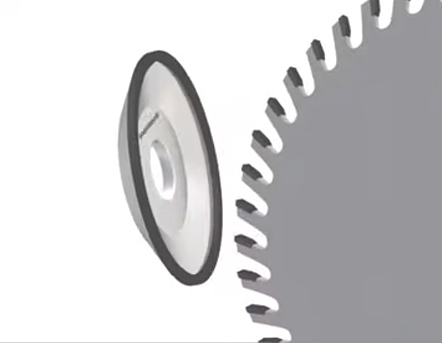

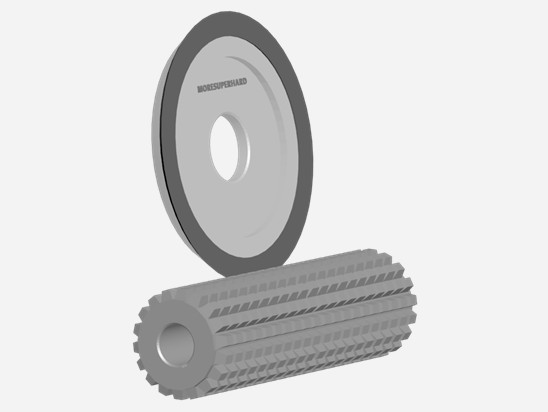

Double bevel grinding wheel: mainly used for forming grinding of carbide gear hobs and thread cutters

Bowl-shaped grinding wheel: mainly used for the sharpening of cemented carbide tools and high-speed steel tools, and can also be used for milling