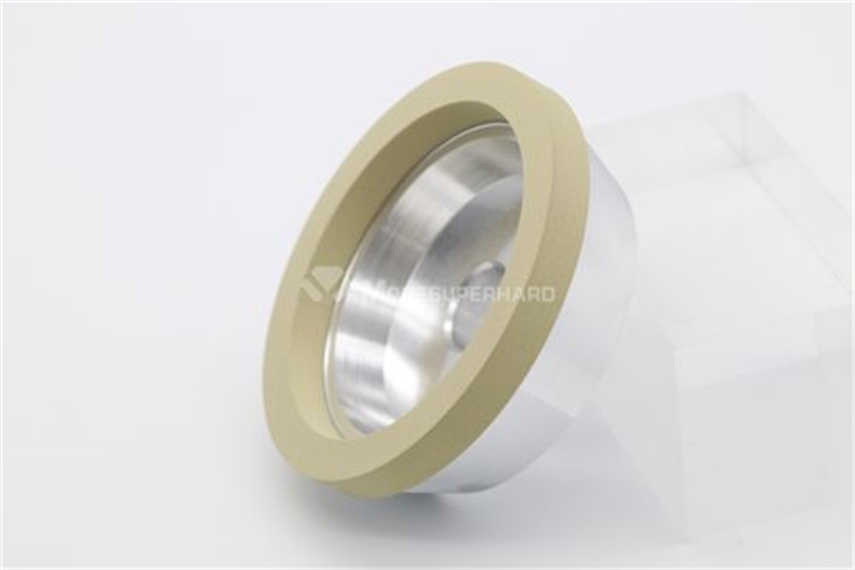

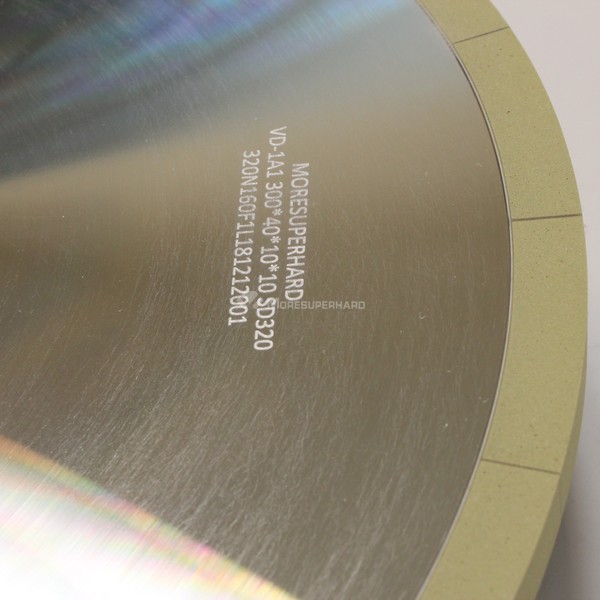

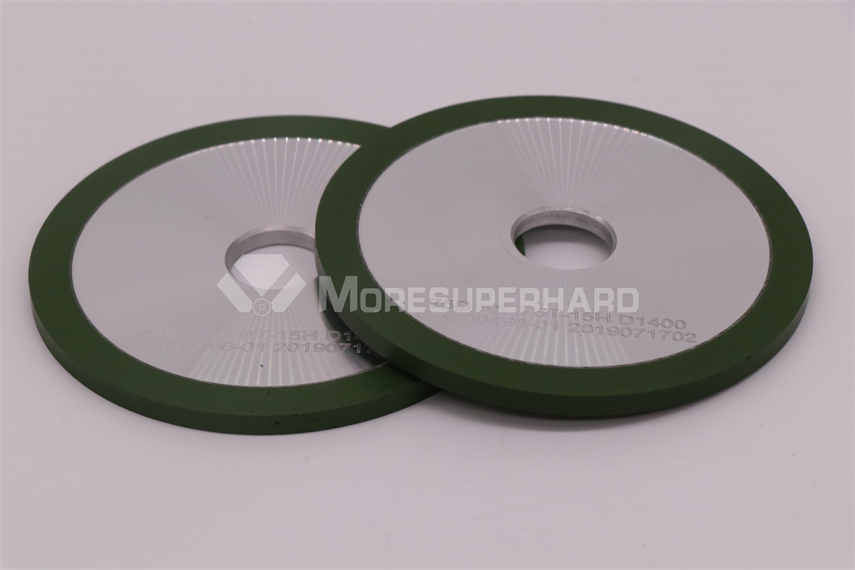

D300 Vitrified bond diamond grinding wheels for sale

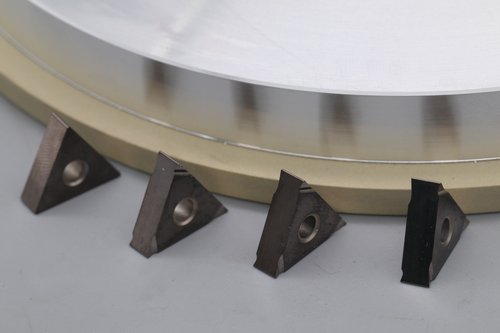

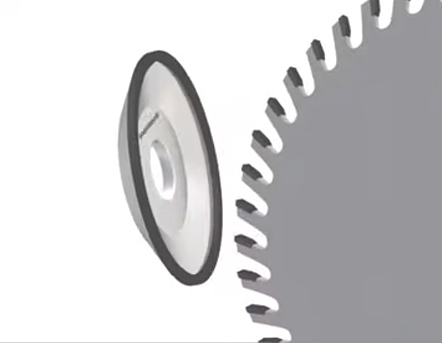

Vitrified bond diamond grinding wheels are mainly used in silicon wafer, semiconductor silicon, Led, polycrystalline diamond compact (PDC), diamond polycrystalline (PCD), diamond cutting tools, cubic boron nitride (CBN), tungsten carbide, ceramics, crystals, magnetic materials, optical glass and other high hard brittle materials machining.

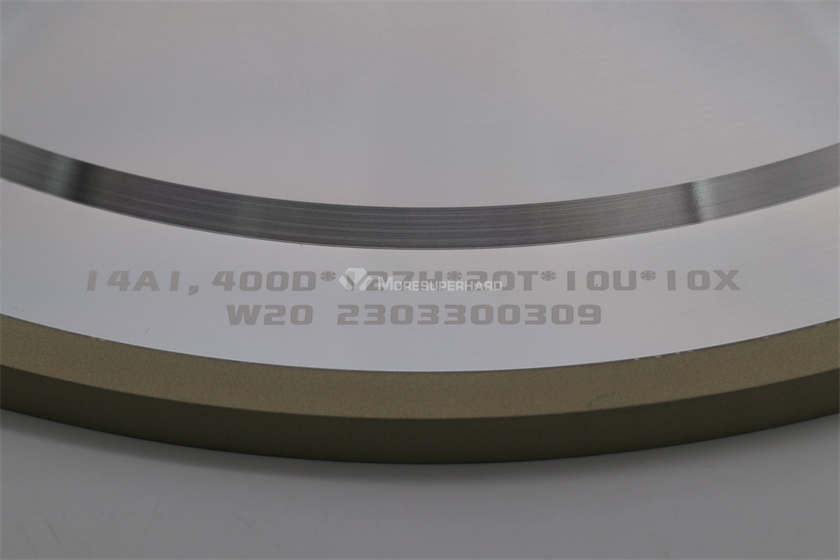

Type: 1a1, 6a2, 14a1, 3a1, 11v9, etc

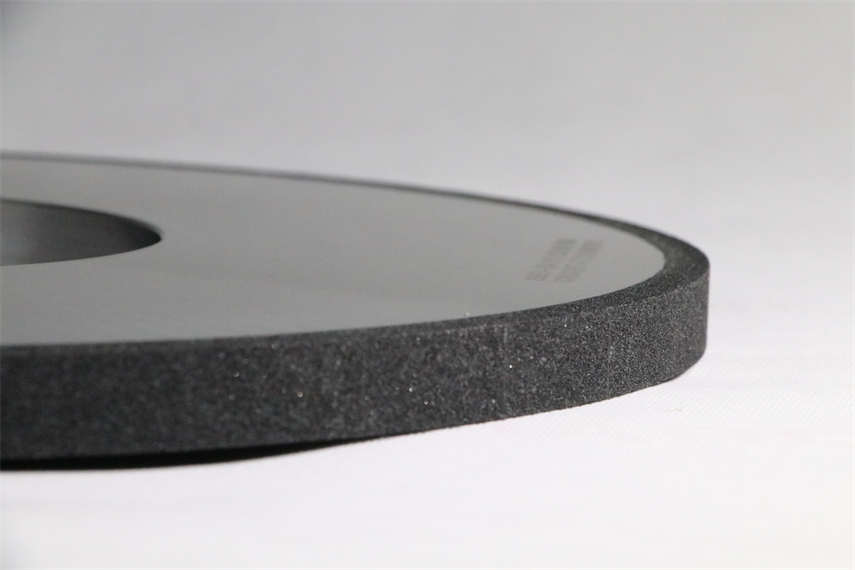

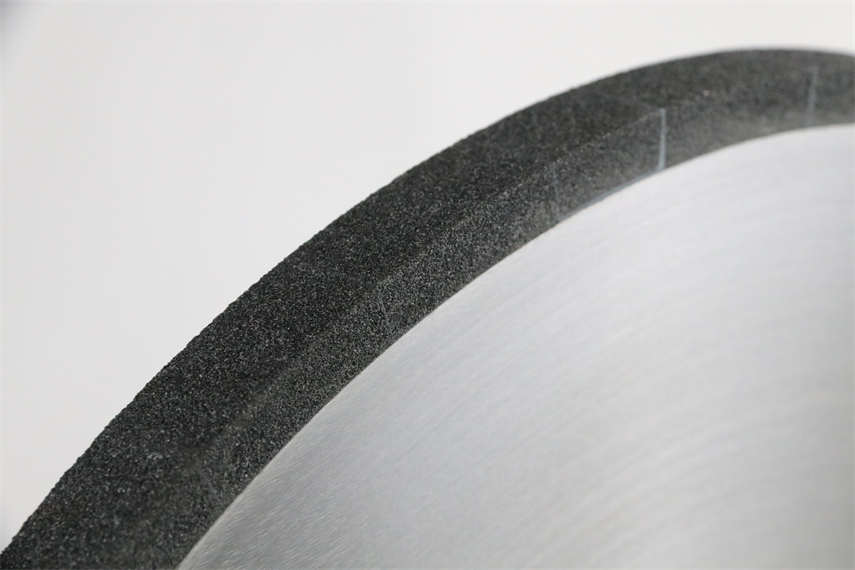

Vitrified bond diamond CBN grinding wheels allow for the custom tailoring of a grinding wheel structure specific to a customer’s material and grinding process, resulting in an efficient grinding process where wheel life and cycle times are optimized for lowest costs and highest work piece quality.

Advantages of vitrified bond diamond grinding wheels

100-300 Times the Life of conventional grinding wheels in comparable applications.

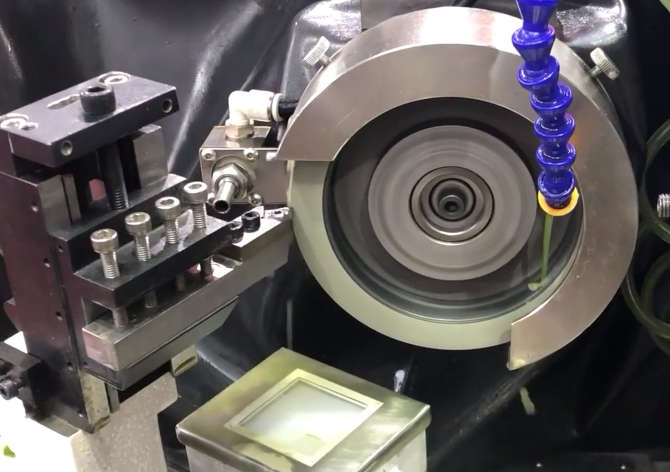

Efficient Heat Removal with open structures that carry coolants into the work zone resulting in less thermal damage to metals when compared with other bond systems.

Improved Cycle Times Decreased down time, wheel dressing and/or wheel changes when compared with conventional and resin bonded superabrasive applications.

Lights Out Operation is possible with dressable structures as layer depths allow for continual renewing of the grinding layer.

Re-Truing of Formed Profiles and formed structures are possible using Diamond tools and rotary dressers.

Customization of grinding wheel specifications for unique customer applications.