Diamond/CBN Grinding Head for Internal Grinding

Usage:

1. Especially used for internal grinding of complex workpieces.

2. Used for dressing abrasive tools.

3. Used for processing industrial ceramics.

4. Suitable for processing and polishing cemented carbide, various molds, stone, glass, jade, gems, teeth, bones, high-speed steel and various high-hardness materials.

What is the diamond/CBN internal grinding head?

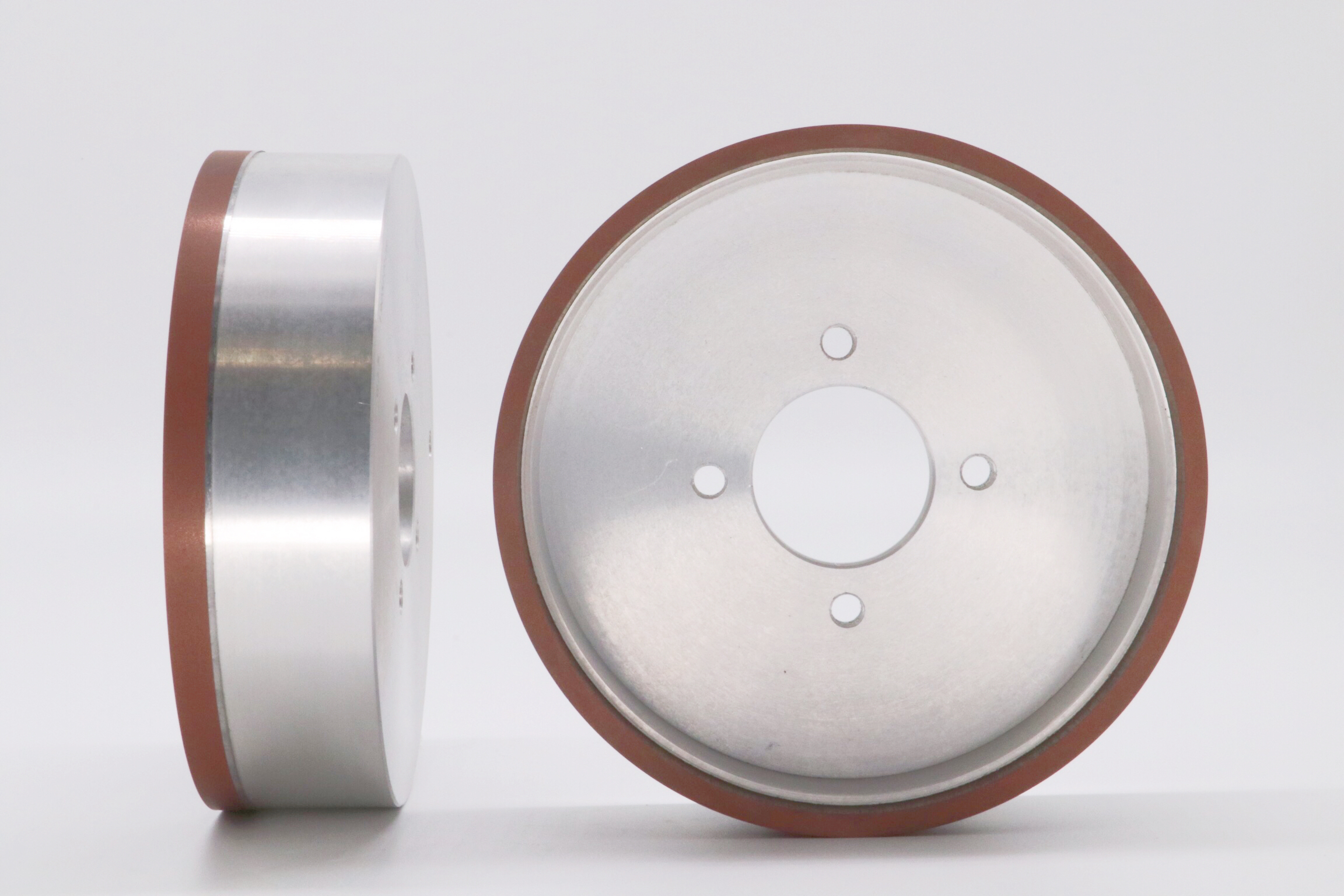

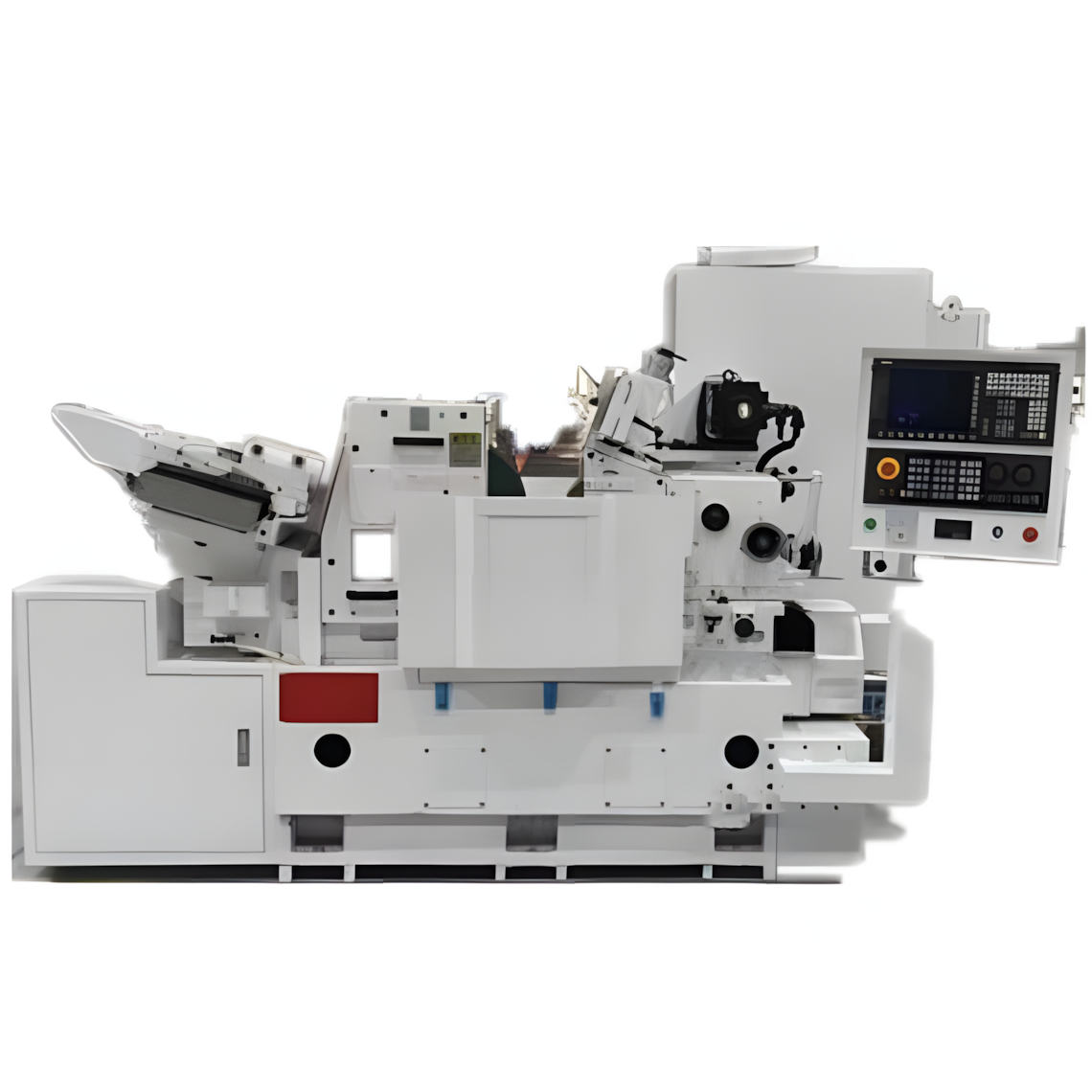

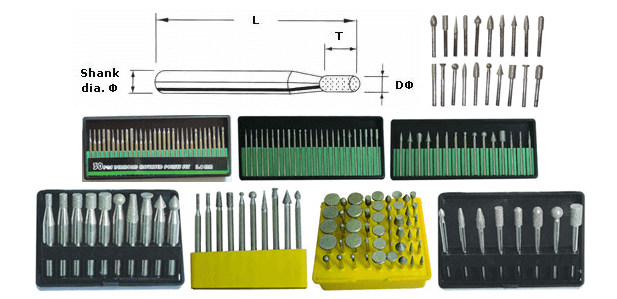

Details: The diamond/CBN grinding head is one kind of grinding head and abrasive, which is bonded with a certain bonding agent, generally installed in grinder, grinding machine, polishing machine, or special installation tools, etc. It is widely used in optical lenses, prism, watch glass, sapphire glass. It is widely used for the optical lens, prism, watch glass, sapphire glass, etc. By processing various workpieces, it can achieve the effect of grinding, polishing and buffing. According to the use, it is mainly divided into the following types of grinding heads:

What are the types of internal grinding?

- Grinding type. The internal grinding head is mainly installed on the grinding machine to grind and polish the workpiece, such as internal grinding, external grinding, etc. It can be divided into rough grinding and fine grinding.

- Burnishing type. Generally used to grind the burrs of the workpiece or to process the surface of the workpiece with low precision. Use the grinding machine, electric, pneumatic tools and other high-speed operation to achieve the effect of grinding.

- Polishing type. Specially used for processing with high requirements for the surface finish (roughness), which is a separate processing process.

Main common shapes: cylindrical grinding head, hemispherical grinding head, circular grinding head, spherical grinding head, conical grinding head, bullet-shaped grinding head.

The main common grit sizes of Moresuperhard’s diamond/CBN internal grinding head: 80#, 100#, 120#, 150#, 180#, 220#, 320#, 400#, 600#, 800#, 1000#, 1200#, 1500#, 2000#, etc. As long as the customer has a sample drawing, we can make satisfactory products according to the customer’s requirements, no matter in terms of product performance or specifications.