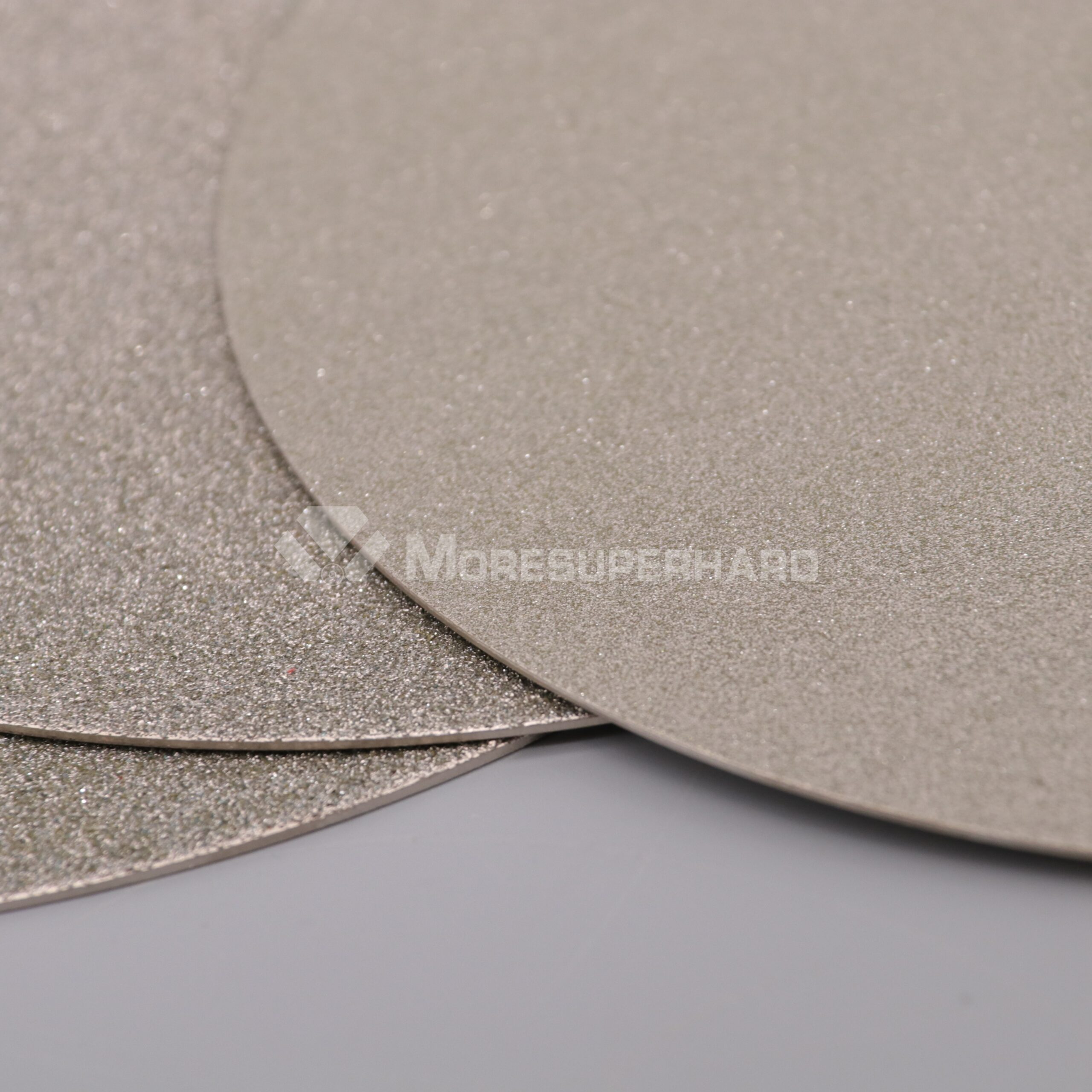

Film Belt for Thermal Spraying Industry

Film belt is for grinding steel, stone, glass, ceramics, mono crystalline silicon, polysilicon, zirconia, alumina, metal-nonmetallic synthetic materials, cemented carbide, aluminum-magnesium alloy, aluminum beryllium alloy, titanium alloy and etc. hard brittle materials.

Introduction:

1. Film belt is for grinding steel, stone, glass, ceramics, monocrystalline silicon, polysilicon, zirconia, alumina, metal-nonmetallic synthetic materials, cemented carbide, aluminum-magnesium alloy, aluminum beryllium alloy, titanium alloy and etc. hard brittle materials.

2. Film belt’s excellent chemical resistance makes it a good choice in areas where many solvents, acids, and oils are present.

3. Features a closed coat construction for finish consistency.

4. wide belts are a good match for larger workpieces like stamped parts, sheet metal parts, or dies.

5. Moresuperhard’s belts are designed with a strong polyester film backing and sharp diamond minerals.

Application:

- Motor commutator: for motor commutator surface grinding and polishing; can effectively remove oxidation layer and stain.

- Rolls: surface polishing of metal rolls, ceramic rolls, carbide rolls, hard castings, etc.; with the advantages of good adhesion and high grinding power.

- Hard disk, magnetic head: polishing of magnetic head, hard disk carbon layer; good durability and high grinding efficiency.

- LCD: mainly used for polishing of LCD color filters; efficient removal of defects and stains.

- Semiconductor materials: edge polishing of semiconductor silicon wafers, removing the damage layer on the edge surface and obtaining low surface roughness.

- Crankshaft, camshaft: used for precision grinding and polishing of crankshaft surface, with high grinding force and good polishing effect.