Rockwell Diamond Indenters for Hardness Testing

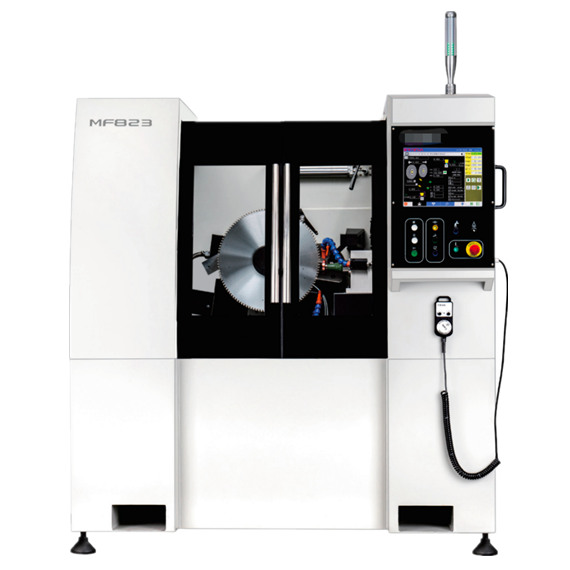

1. Moresuperhard Rockwell hardness tester series combines complex design with technical innovation.

2.A wealth of comfort functions make operation easy, safe, and fast. Modern software and interfaces allow time-saving automation and integration of the hardness tester into any lab.

THE THREE STEPS OF ROCKWELL HARDNESS TESTING

1.The indenter is first pressed into the surface of the specimen with a specific preload F0. This is to exclude influences of the surface on the hardness value, such as scale layers, hardenings, etc. Under this preload, the indenter initially penetrates the specimen by the distance t0. To generate the preliminary test force, the specimen is usually pressed against the indenter until the required test force is applied.

2.In a second step, the additional test force F1 is applied. The indenter now penetrates the specimen by a further amount Dt. The additional test force must be applied (starting from the preload) without shock or vibration and without overshooting within a period of 2-8 s and must be kept constant for 4±2s.

3.In the third step, the load is relieved again up to the preload F0. The indenter moves back upwards by the elastic portion of the deformation tel so that the remaining indentation depth is tbl. The hardness value is either displayed directly on the hardness tester or can be calculated from the measured indentation depth.